Do you have a question about the Carrier XCT 7 40VU005~018C-7S-QEE and is the answer not in the manual?

| Category | Heat Pump |

|---|---|

| Cooling Capacity (kW) | 5.0 ~ 18.0 |

| Refrigerant | R410A |

| Operating Temperature Range (Heating) | -15°C to 24°C |

| Power Supply | 380-415V/3Ph/50Hz |

All products conform to European provision: Machinery Directive and Electromagnetic Compatibility.

Products conform to directive 2011/65/UE on Restriction of Hazardous Substances in Electrical and Electronic Equipment.

Informs consumers about the appropriate disposal of electrical and electronic products as per directive 2012/19/UE.

Product marked with symbol indicates not to mix with household waste; professional disposal is required for environmental safety.

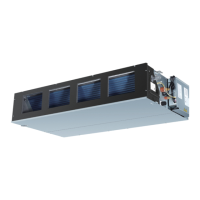

Details the components of the indoor unit, such as the electrical cabinet, inlet grid, air cleaner, and wind deflector.

Covers critical safety considerations for installation, including warnings about improper installation, wiring, and environmental factors.

Details operational cautions regarding grounding, circuit breakers, and attention points for safe operation and maintenance.

Details the regular tasks for maintaining the air conditioner, including cleaning the filter and air inlet grid.

Provides instructions on how to clean the air cleaner filter using a vacuum cleaner or water, and how to dry it properly.

Guides on how to mount the gauze and the air inlet grid back into the indoor unit after cleaning.

Instructions for cleaning the air outlet port and the unit's shell using appropriate cleaning agents and methods.

Advises on how to clean the wind deflector without using forceful water jets to prevent discoloration.

Outlines maintenance tasks required before the operating season and after the operating season for optimal performance.

Lists common operational concerns and their possible causes, including sounds, smells, and indicator issues.

Addresses common problems like bad cooling or heating effects, guiding checks for blockage, settings, and temperature.

Guides on selecting suitable locations for indoor units, avoiding specific environmental conditions and ensuring proper clearance.

Details the required distances between the ceiling hole, the indoor unit, and the hoisting studs for proper installation.

Provides steps for drilling the ceiling hole and reinforcing the area for secure indoor unit foundation.

Guides on hoisting the indoor unit using studs and ensuring it is level, including details on the drainage pump and floater switch.

Instructions for preparing and fitting the trim panel, including checks for angle, water level, and screw fastening.

Details the mounting of the decorative panel, including alignment, screw fastening, and connecting wiring for motors and remote controls.

Specifies piping materials, requirements for heat insulation to prevent condensation, and drainpipe installation guidelines.

Describes how to use the attached hose for eccentricity adjustment and proper placement of the hose with a clamp.

Details the permissible lift height for the drainpipe and procedures for confirming proper drainage during the test run.

Covers tubing length, height difference, materials, specifications, and refrigerant filling quantity requirements.

Provides instructions for connecting refrigerant tubing using flare nuts, including torque specifications and proper connection techniques.

Covers safety warnings for electrical connections, grounding, wire types, and general wiring precautions for safe installation.

Illustrates supply wiring diagrams for outdoor and indoor units, detailing circuit breaker requirements and voltage specifications.

Presents a detailed signal wiring diagram illustrating connections between outdoor, indoor, and wired controllers.

Specifies wiring dimensions, cross-sectional areas for power and signal lines, and grounding requirements.

Explains the definition and description of SW01 for setting indoor unit capabilities and addresses for wired controllers.

Details the definition and description of SW03 for setting indoor unit addresses and centralized controller addresses.

Outlines essential checks before performing the test run, including voltage, leakage, connections, and insulation.

Describes the method for conducting a test run, including compulsive running and checking temperature regulator functionality.

Provides a table of failure codes for wired controllers and indoor unit LEDs, with corresponding fault descriptions for diagnosis.

Provides information according to Directive 2006/42/EC regarding manufacturer details and material composition for safe scrapping.