Motorized valve and control

Instructions for mounting of motorized thermo-

electric valve assembly

(see "Components" table)

The thermo-electric valve must be mounted on the unit after the unit •

installation. For this operation follow gures, depending on model.

Assembly (Fig. 30)

For models 42GWD (4-pipe), the valve assembly for the cold

water coil must be installed rst

.

Connect the valve assemble to the coil and • x it by a 30Nm torque.

Insulate the valve assembly.

Fit the actuator on the valve body, route the cable through the grommet

ref. “e” and x them to the casing using the assembled screw.

To connect the steel pipes to the system, ensure they are aligned and •

supported to avoid excess strain on the unit. If the system is lled

with water, check all tting seals.

After ending the hydraulic connections, make sure there are no leaks. •

Insulate the valve using the shell, x it by means of the clips and make

sure that all cold parts are insulated (g. 29 – 30).

For 4-pipe hot water coil, repeat all the operations with gas adaptors, •

as per the table.

NOTE:

The seal eciency of the valve assembly is factory tested. Any

system losses are therefore due to an incorrect installation.

Operation of the thermo-electric valve (See g. 31)

This 2- 3-way valve is of the OPEN/CLOSE type with very slow travel. •

It is not a modulating valve so it has no PTC.This valve is driven, as a

sensible element, by the ambient thermostat of the “cassette” unit.

The 2-way valve is normally closed to the coil with no powered •

actuator side. The 3-way valve is normally closed to the coil with no

powered actuator side while is open to the bypass way side. When the

room temperature does not satisfy the thermostat, the valve opens

after about 3 minutes about to allow water to circulate in the coil.

If the room temperature satises the thermostat or if the electric •

power has been switched o, the valve is closed after about 3 minutes

towards the coil and is opened towards the bypass.

If an emergency occurs, the valve may be manually opened, removing •

the electric head, unscrewing the ring nut.

When the emergency ends, remember to reset the valve to

automatic operation, repositioning the electric head; failure to

do this can result in condensate formation due the water pipes,

even if the unit is switched o.

Instructions for eld supplied valves

Water connection

Install valves following manufacturer's instructions; refer to the •

relevant gures for connection to the unit.

Carefully insulate pipes, valve assemblies and coil connections (cold •

water side) to avoid condensation forming on the pipes and dripping

on the false ceiling.

Electrical wiring

Connect the room control following instructions for the control used.•

WARNING:

Pass cables through the control panel cable-conduit.

Connect the valves according to the instructions and the wiring •

diagrams attached to the machine documents.

Valves, closing the unit water inlet when there is no power •

supply, must be used.

ON-OFF valves (230V)

The chilled water valve must be operated by the 230V on-o signal •

from terminal 1 of TB3 and the hot water valve from terminal 2 of TB3.

If these connections are not made as described the drain pan •

condensate may overow.

Valves should open only when the fan is working, that is, when one of •

terminals V1, V2, V3 is energized by L mains supply.

The optional electric heater (mod. 42GWE) which can only be factory •

installed, must only be energized when the fan is working.

The electric heater (if any) is operated only if a 230 V voltage is •

supplied to terminals 2 and 4 of the electronic board.

NOTE: When the system is lled with water, verify all couplings •

for tightness.

The manufacturer does not accept responsibility for the tightness •

of the eld - installed valve assembly and this is not tested in the

factory.

He declines any responsibility for non functioning of these •

assemblies and for damage due to dripping.

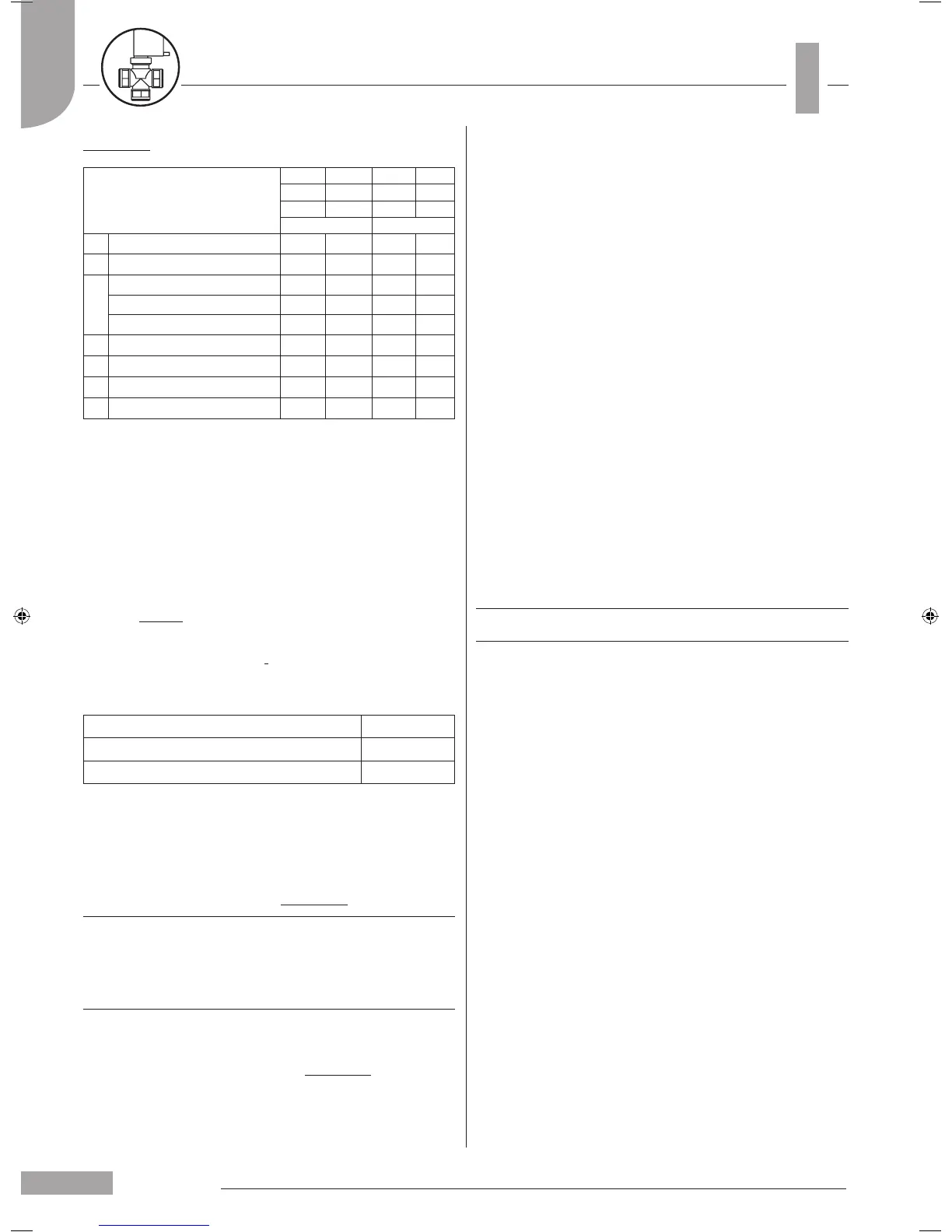

Mod. 42GW...B

004 012 004 020

008 016 008

010 020 010

2-pipe 4-pipe

Ref.

Description q.ty q.ty q.ty q.ty

a Actuator 1 1 2 2

b

Valve 1"gas pre-assembled 1 1

Valve 3/4" gas pre-assembled 1 1 1

Valve 1/2" gas pre-assembled 1

c Shell 1 1 1 1

d Clips 3 3 3 3

e Cable holder 1 1 1 1

f Gasket 2 2 4 4

Motorized thermo-electric valve assembly and components

(See g. 28).

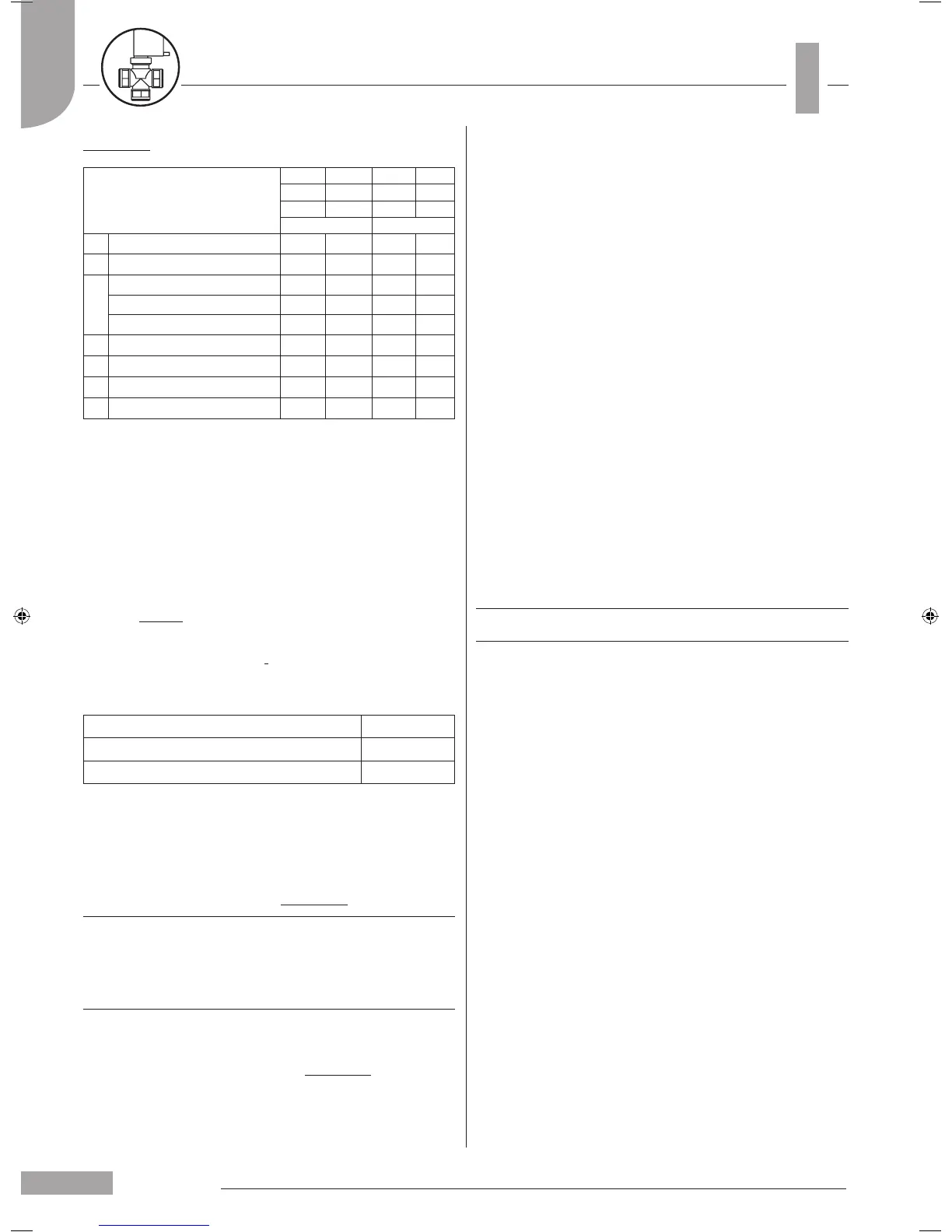

Gasket type Nm

Rubber 10/12

Fibre 25/30

Loading...

Loading...