1 2

4 3

C00070b

SEE DETAIL

DETAIL A

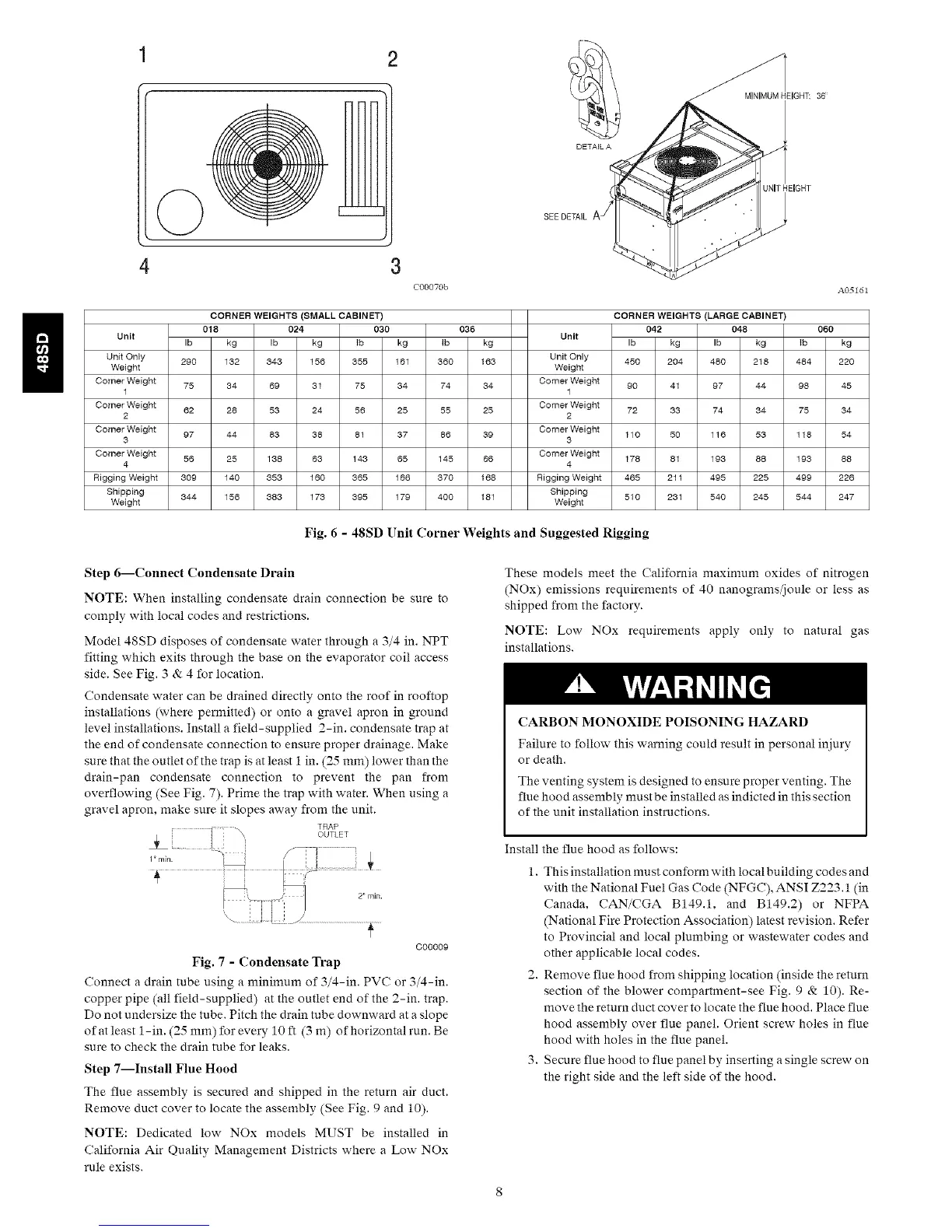

CORNER WEIGHTS (SMALL CABINET)

018 024 030 036

Unit Unit

Ib kg Ib kg Ib kg Ib kg

Unit Only 290 132 343 156 355 161 360 163 Unit Only

Weight Weight

Corner Weight 75 34 69 31 75 34 74 34 Corner Weight

1 1

Corner Weight 62 28 53 24 56 25 55 25 Corner Weight

2 2

Corner Weight 97 44 83 38 81 37 86 39 Corner Weight

3 3

Corner Weight 56 25 138 63 143 65 145 66 Corner Weight

4 4

Rigging Weight 309 140 353 160 365 166 370 168 Rigging Weight

Shipping 344 156 383 173 395 179 400 181 Shipping

Weight Weight

MINIMUMHEIGHT: 36'

UNITHEIGHT

A05161

CORNER WEIGHTS (LARGE CABINET)

042 048 060

Ib kg Ib kg lb kg

450 204 480 218 484 220

90 41 97 44 98 45

72 33 74 34 75 34

110 50 116 53 118 54

178 81 193 88 193 88

465 211 495 225 499 226

510 231 540 245 544 247

Fig. 6 - 48SD Unit Corner Weights and Suggested Rigging

Step 6--Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Model 48SD disposes of condensate water through a 3/4 in. NPT

fitting which exits through the base on the evaporator coil access

side. See Fig. 3 & 4 for location.

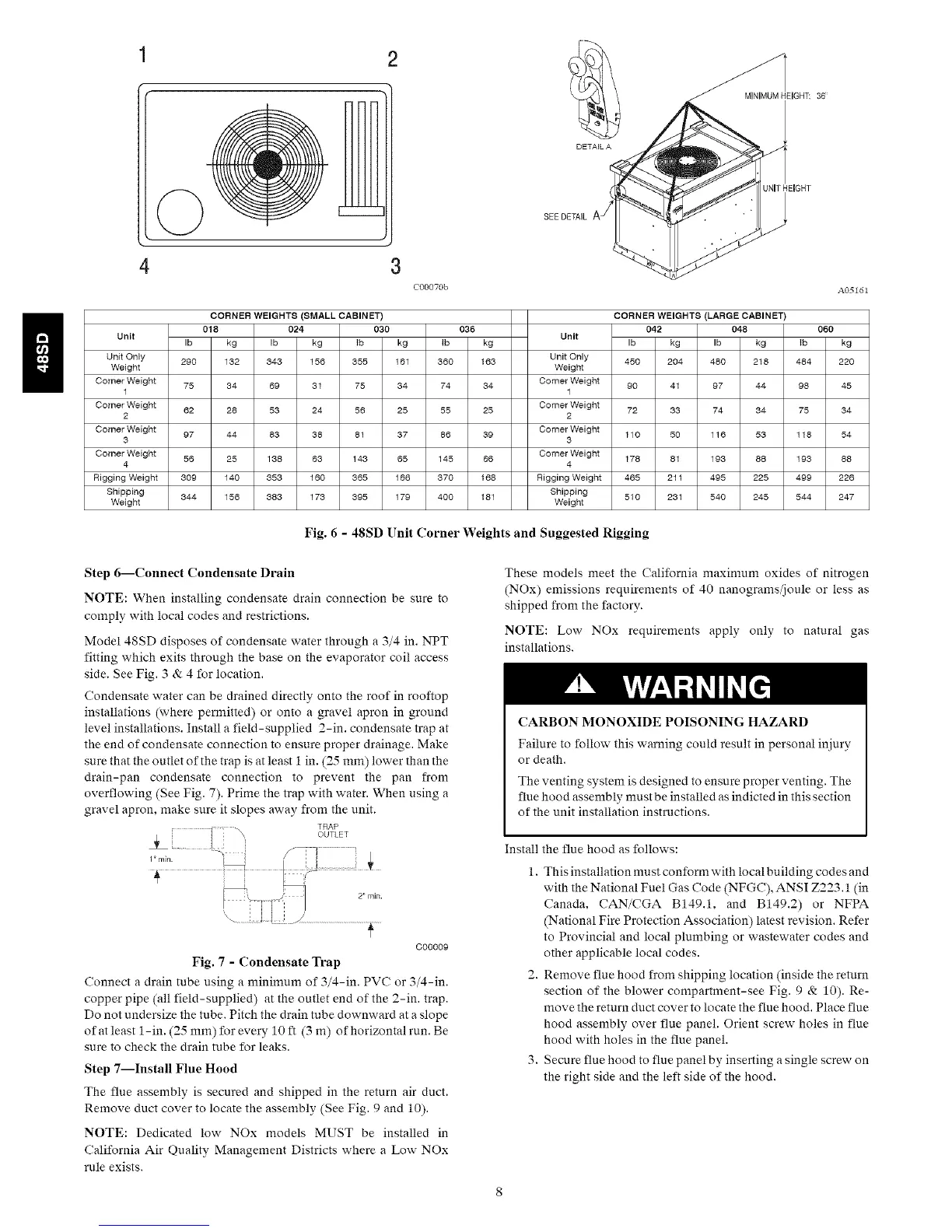

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in ground

level installations. Install a field-supplied 2-in. condensate trap at

the end of condensate connection to ensure proper drainage. Make

sure that the outlet of the trap is at least i in. (25 mm) lower than the

drain-pan condensate connection to prevent the pan from

overflowing (See Fig. 7). Prime the trap with water. When using a

gravel apron, make sure it slopes away from the unit.

TRAP

OUTLET

C00009

Fig. 7 - Condensate Trap

Connect a drain tube using a minimum of 3/4-in. PVC or 3/4-in.

copper pipe (all field-supplied) at tire outlet end of the 2-in. trap.

Do not undersize the tube. Pitch the drain tube downward at a slope

of at least 1-in. (25 mm) for every 10 ft (3 m) of horizontal run. Be

sure to check the drain tube for leaks.

Step 7--Install Flue Hood

The flue assembly is secured and shipped in the return air duct.

Remove duct cover to locate the assembly (See Fig. 9 and 10).

NOTE: Dedicated low NOx models MUST be installed in

California Air Quality Management Districts where a Low NOx

rule exists.

These models meet the California maximum oxides of nitrogen

(NOx) emissions requirements of 40 nanograms/joule or less as

shipped from the factory.

NOTE: Low NOx requirements apply only to natural gas

installations.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

The venting system is designed to ensure proper venting. The

flue hood assembly must be installed as indicted in this section

of the unit installation instructions.

Install the flue hood as follows:

1. This installation must conform with local building codes and

with the National Fuel Gas Code (NFGC), ANSI Z223.1 (in

Canada, CAN/CGA B149.1, and B149.2) or NFPA

(National Fire Protection Association) latest revision. Refer

to Provincial and local plumbing or wastewater codes and

other applicable local codes.

2. Remove flue hood from shipping location (inside the return

section of the blower compartment-see Fig. 9 & 10). Re-

move the return duct cover to locate the flue hood. Place flue

hood assembly over flue panel. Orient screw holes in flue

hood with holes in the flue panel.

3. Secure flue hood to flue panel by inserting a single screw on

the right side and the left side of the hood.

Loading...

Loading...