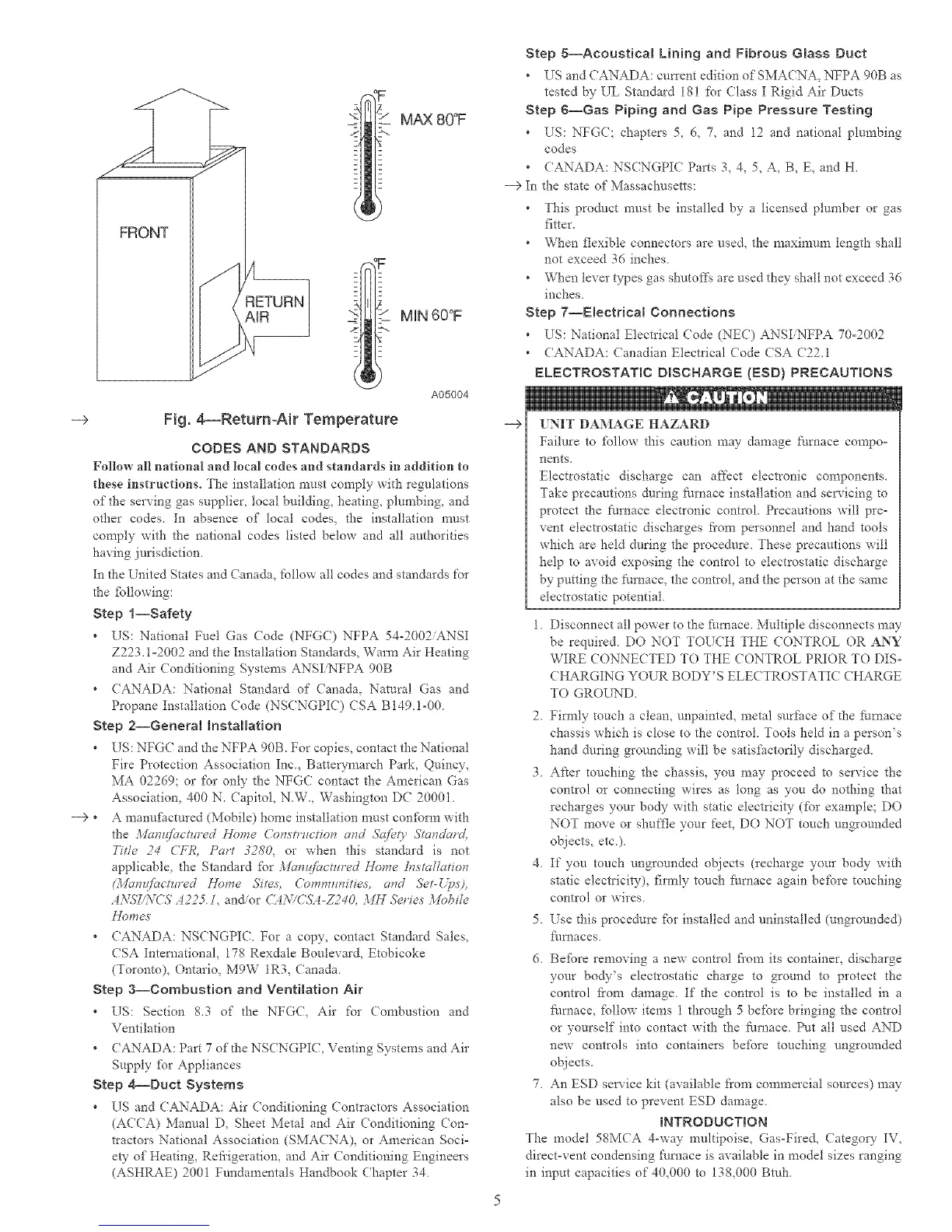

"} MAX 80°F

--z

FRONT

RETURN

AHR

MHN60°F

A05004

--)

Fig. 4--Return-Air Temperature

CODES AND STANDARDS

FMlow all national and locM codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving gas supplier, local building, heating, phlmbing, and

other codes. In absence of" total codes, the installation must

comply with the national codes tisted below and all authorities

having jurisdiction.

In the L nited States and Canada, follow 311codes and standa*ds for

the fbllowing:

Step l--Safety

* US: National Fuel Gas (ode (NFGC) NFPA 54-2002/ANSI

Z223.1 °2002 and the Installation Standards, Warm Air Heating

and Air (onditioning Systems ANSI NFPA 90B

* CANADA: National Standard of Canada, Natural Gas and

Propane Installation Code (NSCNGPIC) (SA BI49 !-00

Step 2--General hsta[[ation

* ETS: NFGC and the NFPA 90B. For copies, contact the National

Fire Protection Association Inc, Batterymarch Park, Quincy,

MA 02269: or for only the NFGC contact the American Gas

Association, 400 N. Capitol, N.W, Washington DC 20001.

A manufhcmred (Mobile) home installation must con%tin with

the :_I(mz!/actu_'ed ]iT)me ('or_sh'uctio_ at_d ,_q_et3' St(md(t_'d,

Title 24 (_FR, Pco't 3280, or when this standard is not

applicable, the Standard fbr __!am(fi_ctured Hnme inst(dlatins_

(Memo(lactated _))me Sites, ('ommzmitie.z and Set-LW.U,

AN,_;ILVC_' A225.1, an_or C4:\',(',%1-Z240, MH SeHe.s Mobile

Momes

* CANADA: NSCNGPIC For a copy_ contact Standard Sales,

(SA International, 178 l_.exdale Boulevard, Etobicoke

(Toronto), Ontario, M9W IR3, (anada

Step a--Combustion and Ventilation Air

* US: Section g.3 of the NFGC, Air for (ombustion and

Ventilation

* CANADA: Part 7 of d-_€NSCNGPIC, Venting Systems and Air

Supply %r Appliances

Step 4=-Duct Systems

* US and CANADA: Air (onditioning (ontractors Association

(ACCA) Manual D, Sheet Metal and Air Conditioning (:on=

tractors National Association (SMACNA), or American Soci=

ew of Heating, Refrigeration, and Air Conditioning Engineers

(ASHRAE) 200I Fundamentals Handbook Chapter 34

--> In

--9

Step 5--Acoustical Lining and Fibrous Glass Duct

* US and (ANADA: current edition of SMA(NA, NFPA 90B as

tested by UL Standard 18! for Class I Rigid Air Ducts

Step 6--Gas Piping and Gas Pipe Pressure Testing

* [IS: NFGC; chapters 5, 6, 7, and 12 and national plumbing

codes

(ANADA: NS(NGPI( Parts 3, 4, 5, A, B, E, and H.

the state of Massachusetts:

This product must be installed by a licensed plumber or gas

fitter.

When flexible connectors are used, the n_axinmm length shall

not exceed 36 inches

When lever types gas shutot't_ are used they shall not exceed 36

inches.

Step 7--Electrical Connections

* US: National Electrical (ode (N'E() ANSIiNFPA 70°2002

CANADA: (anadian Electrical (ode CSA C22.1

ELECTROSTATIC DISCHARGE {ESD) PRECAUTIONS

[NIT DAMAGE HAZARD

Failure to follow this caution may damage if/mace compo=

rights,

Electrostatic discharge can affect electronic components.

Take precautions during furnace installation and servicing to

protect d_e furnace electronic control. Precautions will pre-

vent electrostatic discharges fi'om personnel and hand tools

which are held during the procedure. These precautions will

help to avoid exposing the control to electrostatic discharge

by putting the t:ornace, the control, and the person at the same

electrostatic potential

1. Disconnect all power to the fhmace. Multiple disconnects may

be required DO NOT TOU(H THE CONTROL OR ANY

WIRE CONNEr TED TO THE ( ONTROL PRIOR TO DIS-

(HARGING YOUR BODY'S ELE(;TROSTATI( CHARGE

TO GROUND.

2 Firmly touch a clean, unpainted, metal surface of the furnace

chassis which is close to the control. Tools held in a person's

hand during grounding will be satisfactorily discharged.

3 After touching the chassis, you may proceed to service the

control or connecting wires as tong as you do nothing that

recharges your body with static electrici V (fbr example; DO

NOT move or shuffle your feet, DO NOT touch ungrounded

objects, etc.).

4. If you touch ungrotmded objects (recharge your body with

static electricity), firmly touch fhmace again befbre touching

control or wires.

5. Use this procedure for installed and uninstalled (ungrounded)

_t/fllaces

6. Before removing a new contact fi'om its container, discharge

your bo@'s electrostatic charge to ground to protect tlae

control fi'om damage. If d_e control is to be installed in a

fhmace, fbllow items 1 through 5 befbre bringing the contlol

or yourself into contact with the ftm_ace. Put all used AND

new controls into containers be%re touching ungrounded

objects.

7. An ESD service kit (available t'rom commercial sources) may

also be used to prevent ESD damage.

INTRODUCTION

The model 58MCA 4-way muhipoise, Gas-Fired, Category IV,

direct=vent condensing furnace is available in model sizes ranging

in input capacities of 40,000 to 13g,000 Btuh.

Loading...

Loading...