Do you have a question about the Carrier 61WG 020 and is the answer not in the manual?

Guidelines for safe installation procedures and damage checks.

Safety precautions and logbook recommendations for maintenance.

Safety guidelines for refrigerant circuit repairs and unit maintenance.

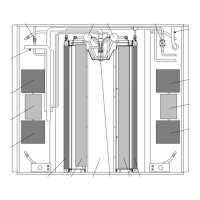

Dimensional data for standard 61WG/30WG 020-045 units.

Dimensional data for standard 61WG/30WG 050-090 units.

Dimensional data for standard 30WGA 020-045 units.

Physical specifications and operating weights for 61WG models.

Physical specifications and operating weights for 30WG models.

Electrical specifications including voltage, current, and power ratings.

Defines the operational limits for 61WG units.

Specifies water flow rates for various unit models and configurations.

Guidance on the minimum required water loop capacity for stable operation.

Requirements and guidelines for the unit's power supply connection.

Guidance on selecting appropriate wire sizes for electrical connections.

Safety precautions and procedures for field control wiring.

Procedures for installing and connecting refrigerant piping.

Guidelines for sizing discharge pipes to ensure proper refrigerant flow.

Precautions for connecting and operating water circuits.

Steps for adjusting water flow rate using control valves.

Understanding pump performance curves for hydronic modules.

Operating principles for 61WG units with specific heating control.

Essential checks before unit start-up.

Procedure for adjusting refrigerant charge for optimal performance.

Configuration for master/slave operation of multiple units.

Information on hermetic scroll compressors and refrigerant used.

Details on compressor lubricant type and checking oil levels.

Identifying and rectifying refrigerant undercharge issues.

Methods and importance of detecting refrigerant leaks.

Procedures for evacuating the system to remove moisture and air.

Properties and pressure-temperature data for R-410A refrigerant.

Scheduled maintenance tasks and frequencies for optimal performance.

Detailed descriptions of maintenance tasks for various service levels.

Checks to ensure the unit is ready for start-up and undamaged.

Verification of connected air handling systems and water valves.

Checks related to unit start-up, including pump interlock and oil level.

| Brand | Carrier |

|---|---|

| Model | 61WG 020 |

| Category | Air Conditioner |

| Language | English |

Loading...

Loading...