F97CMN and G97CMN: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

16

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. This panel MUST be in place when only side return

air is used. Where required by code, seal bottom closure to furnace with

tape, mastic or other durable sealing method.

NOTE: Side return-air openings can be used in UPFLOW and some

HORIZONTAL configurations. Do not use side return-air openings in

DOWNFLOW configuration, see Fig. 20, Fig. 21, Fig. 22.

Downflow Installation

NOTE: The furnace must be pitched as shown in Fig. 18 for proper

condensate drainage.

Supply Air Connections

NOTE: For downflow applications, this furnace is approved for use on

combustible flooring when any one of the following 3 accessories are

used:

1. Determine application being installed from Table 4.

2. Construct hole in floor per Table 4 and Fig. 24.

3. Construct plenum to dimensions specified in Table 4 and Fig. 24.

4. Install special base coil assembly or coil box as shown in in Fig. 24.

NOTE: It is recommended that the perforated supply-air duct flanges be

completely removed from furnace when installing the furnace on a

factory-supplied cased coil or coil box. To remove the supply-air duct

flange, use wide duct pliers or hand seamers to bend flange back and

forth until it breaks off. Be careful of sharp edges, see Fig. 19.

The return-air duct must be connected to return-air opening (bottom

inlet). DO NOT cut into casing sides (left or right). Bypass humidifier

connections should be made at ductwork or coil casing sides exterior to

furnace, see Fig. 21.

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used in downflow applications. To remove bottom closure panel,

see Fig. 23.

Horizontal Installation

NOTE: The furnace must be pitched forward as shown in Fig. 18 for

proper condensate drainage.

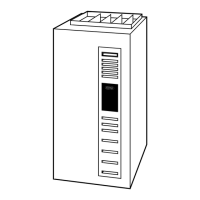

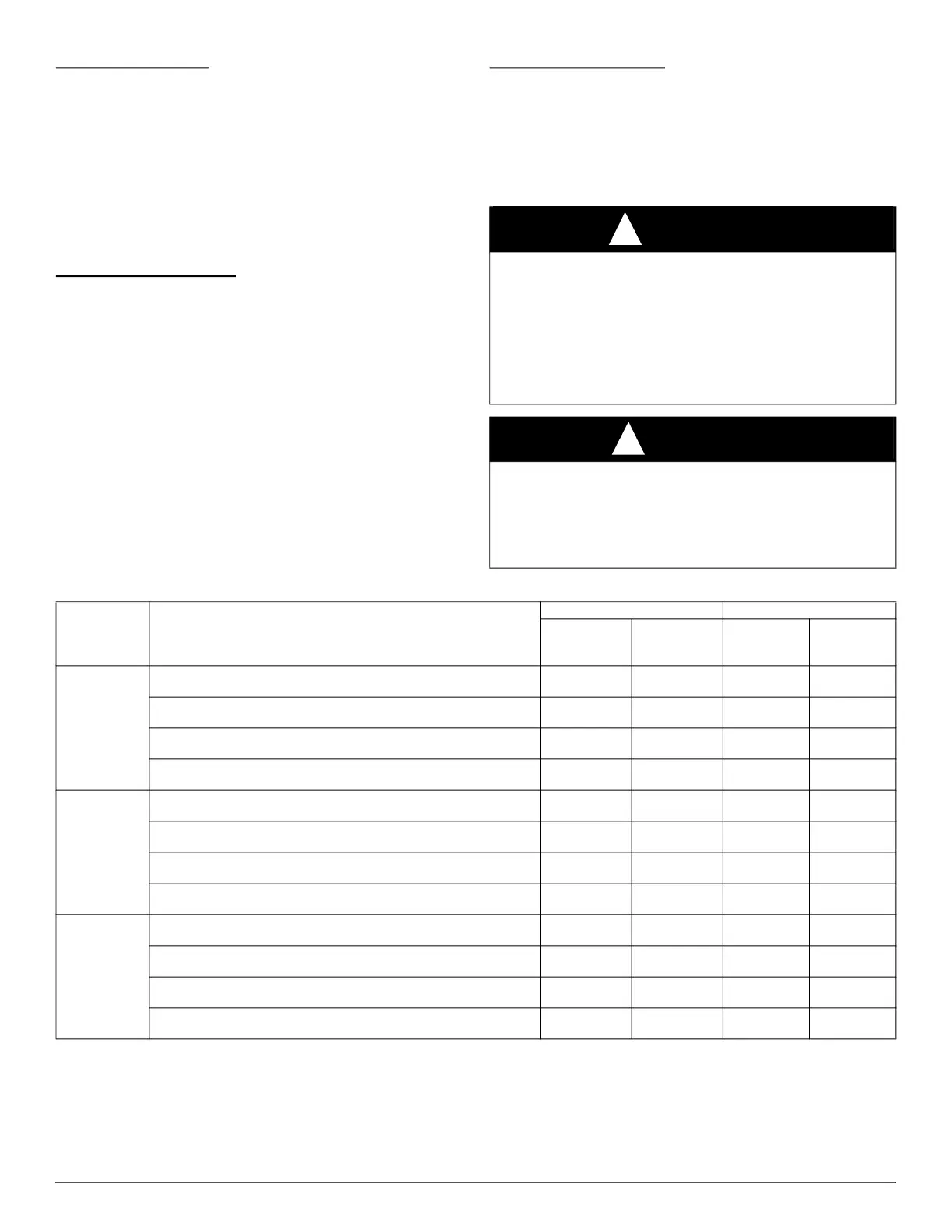

Table 5 – Opening Dimensions - In. (mm)

WARNING

!

FIRE, EXPLOSION, AND CARBON MONOXIDE

POISONING HAZARD

Failure to follow this warning could result in personal injury, death, or

property damage.

Do not install the furnace on its back or hang furnace with control

compartment facing downward. Safety control operation will be

adversely affected. Never connect return-air ducts to the back of the

furnace.

CAUTION

!

MINOR PROPERTY HAZARD

Failure to follow this caution may result in minor property damage.

Local codes may require a drain pan under entire furnace and

condensate trap when a condensing furnace is used in an attic

application or over a finished ceiling.

FURNACE

CASING

WIDTH

IN. (mm)

APPLICATION

PLENUM OPENING FLOOR OPENING

A B C D

17–1/2

(445)

Upflow Applications on Combustible or Noncombustible Flooring

(subbase not required)

16

(406)

21-5/8

(549)

16-5/8

(422)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(subbase not required)

15-7/8

(403)

19

(483)

16-1/2

(419)

19-5/8

(498)

Downflow applications on combustible flooring

(subbase required)

15-1/8

(384)

19

(483)

16-3/4

(425)

20-5/8

(600)

Downflow Applications on Combustible Flooring with Coil Assembly

or coil box (subbase not required)

15-1/2

(394)

19

(483)

16-1/2

(419)

20

(508)

21

(533)

Upflow Applications on Combustible or Noncombustible Flooring

(subbase not required)

19-1/2

(495)

21-5/8

(549)

20-1/8

(511)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(subbase not required)

19-3/8

(492)

19

(483)

20

(508)

19-5/8

(498)

Downflow applications on combustible flooring

(subbase required)

18-5/8

(473)

19

(483)

20-1/4

(514)

20-5/8

(600)

Downflow Applications on Combustible Flooring with Coil Assembly

or coil box (subbase not required)

19

(483)

19

(483)

20

(508)

20

(508)

24-1/2

(622)

Upflow Applications on Combustible or Noncombustible Flooring

(subbase not required)

23

(584)

21-1/8

(537)

23-5/8

(600)

22-1/4

(565)

Downflow Applications on Noncombustible Flooring

(subbase not required)

22-7/8

(581)

19

(483)

23-1/2

(597)

19-5/8

(498)

Downflow applications on Combustible flooring

(subbase required)

22-1/8

(562)

19

(483)

23-3/4

(603)

20-5/8

(600)

Downflow Applications on Combustible Flooring with Coil Assembly

or coil box (subbase not required)

22-1/2

(572)

19

(483)

23-1/2

(597)

20

(508)

Loading...

Loading...