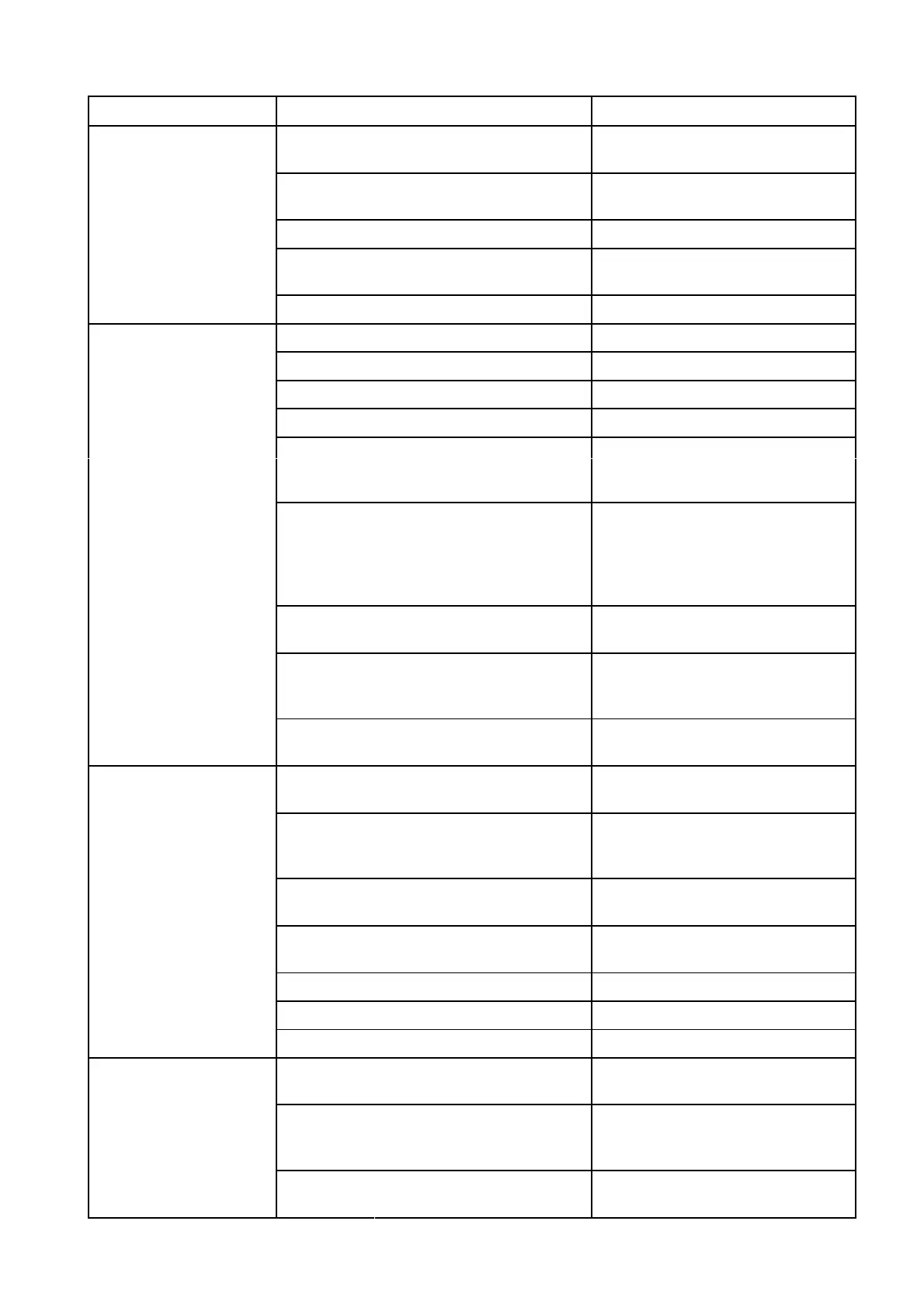

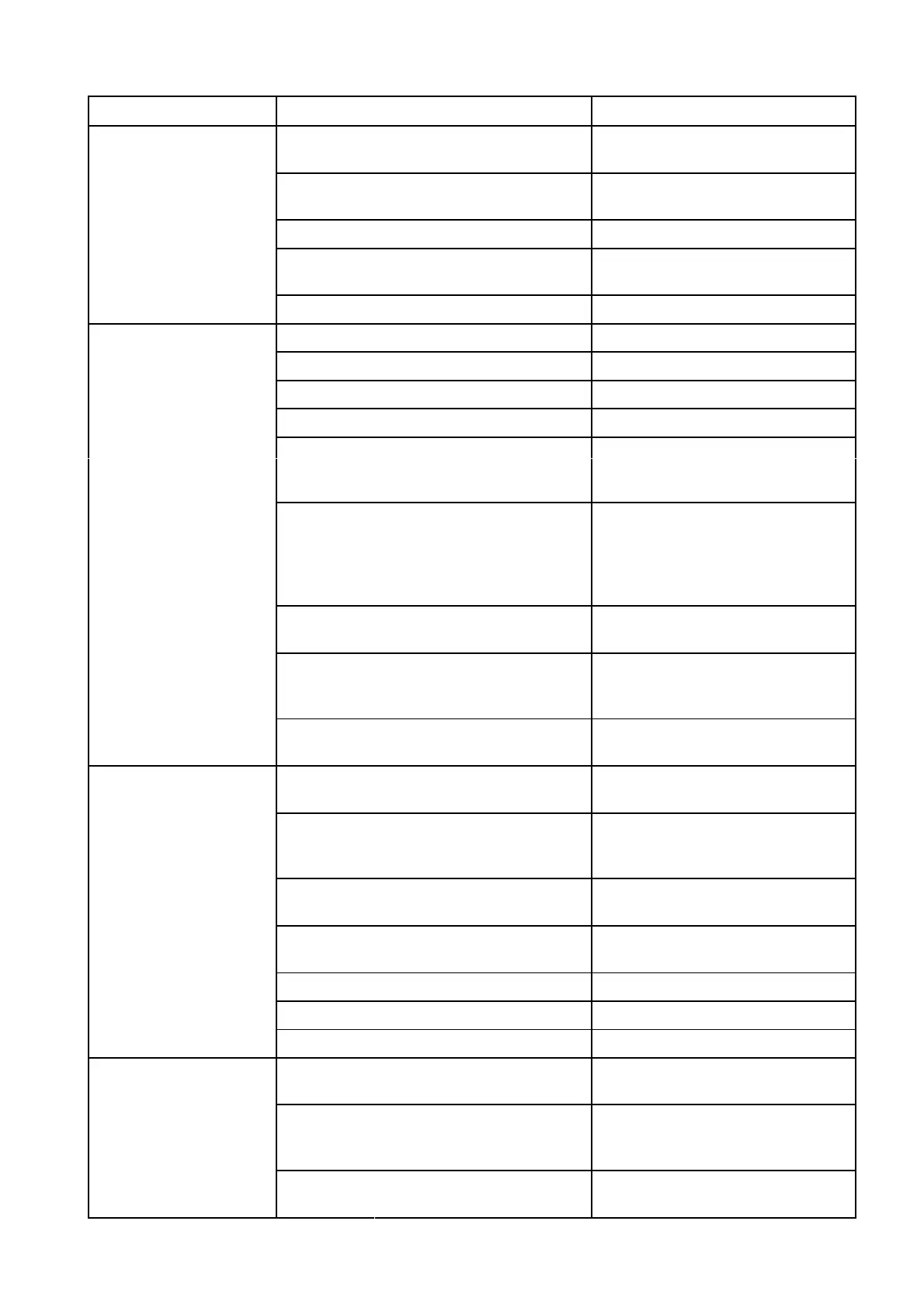

The main pump supplying fuel to unilateral

The main valve rod is stuck and the spring is

Traveling motor is damaged

The upper and lower chambers of swivel

Change the oil seal or clean the

Fuel pipe of traveling system explodes.

Less oil in hydraulic oil tank

Low system safety valve pressure

Adjust to specified pressure

Serious leak inside the main pump

Change or repair the pump

The traveling motor, rotation motor and

cylinder are worn of different degree, which

Change or repair the worn parts

The aged sealing components, worn hydraulic

elements, degraded oil of

old

excavator cause

the operation speed becomes powerless along

with the increase of temperature.

Change hydraulic oil, change sealing

components of the whole machine,

adjust the fit clearance and pressure

of hydraulic components.

decrease of loaded rpm and even flames out.

The blocked hydraulic filter accelerates

Clean and change the element

abrasion of pump, motor and valve and leads

according to the maintenance

Serious between main valve rod and valve

hole causes serious internal leak

Central rotation connector is damaged.

Change the oil seal and change the

The high pressure chamber and low pressure

chamber of traveling operation valve is

Low overloaded pressure of traveling valve

of main valve or the valve rod is stuck.

The left and right traveling reducers fail

The left and right traveling motors fail

Wrong adjustment of variable point of main

valve or serious internal leak of a pump

Internal or external spring of one traveling

valve core of main valve is damaged or

39

Loading...

Loading...