INTRODUCTION

HydraulicHosesandTubes

NOTE:Tighteningthejointtothepropertorquewillkeepitleakfree,andpreventitfromdamagingthehoseortting.

Alwaysreplacehosesandtubeswithdamagedconeendsortheendconnections.

Wheninstallinganewhose,looselyconnecteachendandmakesurethehosetsitsdesiredlocation,withoutkinking

ortwisting,beforetighteningtheconnection.Tightennon-swivelendofhoserstifapplicable.Tightenthehose

clampsenoughtoholdthehosewithoutchangbutnotsotightastocrushtheends.

Keepthehosesandtubesclearofmovingpartsandreplaceanyhosesandttingsthathavemovedfromtheiroriginal

positionsovertime.Ahosewithachafedoutercoverwillallowmoisturetogetintothesystem.Concealedcorrosion

ofthewirereinforcementwillthenoccuralongthehoselengthandresultinhosefailure.

Ballooningofthehoseindicatesinternalleakageasthehosedeteriorates.Thisconditioncanrapidlyleadtohose

failure.

Kinked,crushed,stretchedordamagedhosesgenerallysufferinternalstructuraldamagethatrestrictsuidow,re-

ducesperformanceandultimatelycausesthehosetofail.

Donotallowfreemoving,unsupportedhosesortubestotoucheachotherorrelatedworkingsurfaces.Thiscauses

changandreduceslinelife.

NationalPipeThread(NPT)Fittings

Beforeinstallingandtighteningpipettings,cleanthethreadswithacleaningsolventorLoctite®brandcleaner.Apply

theappropriateLoctite®brandsealanttoallttingsincludingstainlesssteel,unlessasotherwisestated.Generally

Loctite®567™canbeusedforallttingsincludingstainlesssteel.Loctite®565™isusedformostmetalttings.For

highltration/zerocontaminationsystemsuseLoctite®545™.

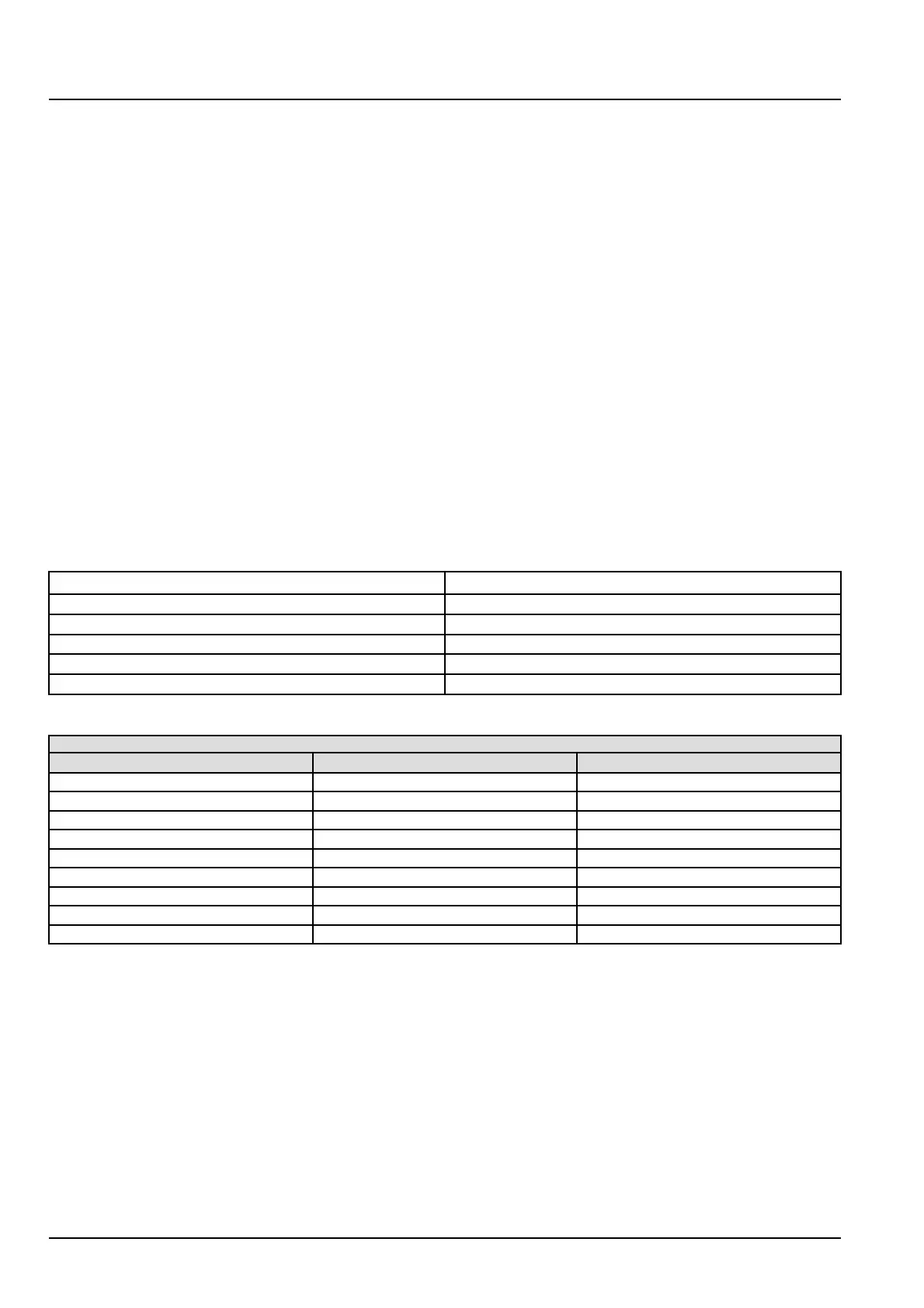

NPTPIPEFITTINGTORQUECHART

ThreadSizeTorque(Maximum)

1/8"-2713Nm(10lbft)

1/4"-1816Nm(12lbft)

3/8"-1822Nm(16lbft)

1/2"-1441Nm(30lbft)

3/4"-1454Nm(40lbft)

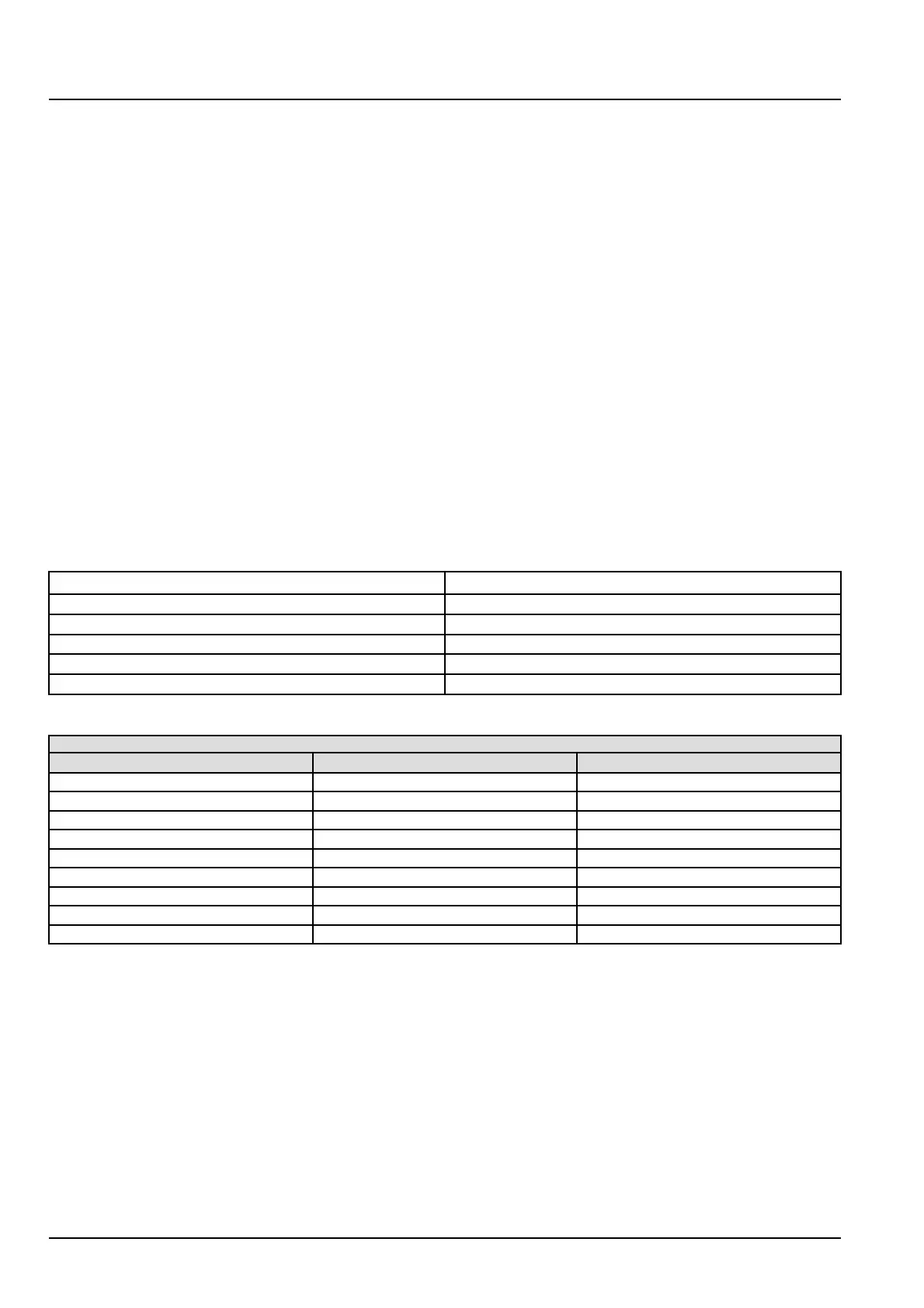

PIPEFITTING

Nom.SAEDashSizeThreadSizeTFFT(TurnsForFingerTight)

-2

1/8-27

2.0-3.0

-4

1/4-18

2.0-3.0

-6

3/8-18

1.5-3.0

-8

1/2-14

2.0-3.0

-12

3/4-14

2.0-3.0

-16

1-11-1/2

1.5-2.5

-20

1-1/4-11-1/2

1.5-2.5

-24

1-1/2-11-1/2

1.5-2.5

-32

2-11-1/2

1.5-2.5

Applysealant/lubricanttomalepipethreads.Thersttwothreadsshouldbeleftuncoveredtoavoidsystemcontam-

ination.Screwpipettingintofemalepipeporttothengertightposition.Wrenchtightenttingtotheappropriate

turnsfromngertight(TFFT)shownintableabove,makingsurethetubeendofanelboworteettingisalignedto

receiveincomingtubeorhosetting.

InstallationofAdjustableFittingsinStraightThreadORingBosses

1.LubricatetheOringbycoatingitwithlightoilorpetroleumjelly.InstalltheOringinthegrooveadjacenttothe

metalbackupwasherwhichisassembledattheextremeendofthegroove.

2.InstallthettingintotheSAEstraightthreadbossuntilthemetalbackupwashercontactsthefaceoftheboss.

NOTE:Donotovertightenanddistortthemetalbackupwasher.

3.Positionthettingbyturningout(counterclockwise)uptoamaximumofoneturn.Holdingthepadofthetting

withawrench,tightenthelocknutandwasheragainstthefaceoftheboss.

4.Whenhoseendsorconnectorsaremadeofmaterialsotherthansteel,differenttorquevaluesmayberequired.

4785194503/02/2016

34

Loading...

Loading...