INTRODUCTION

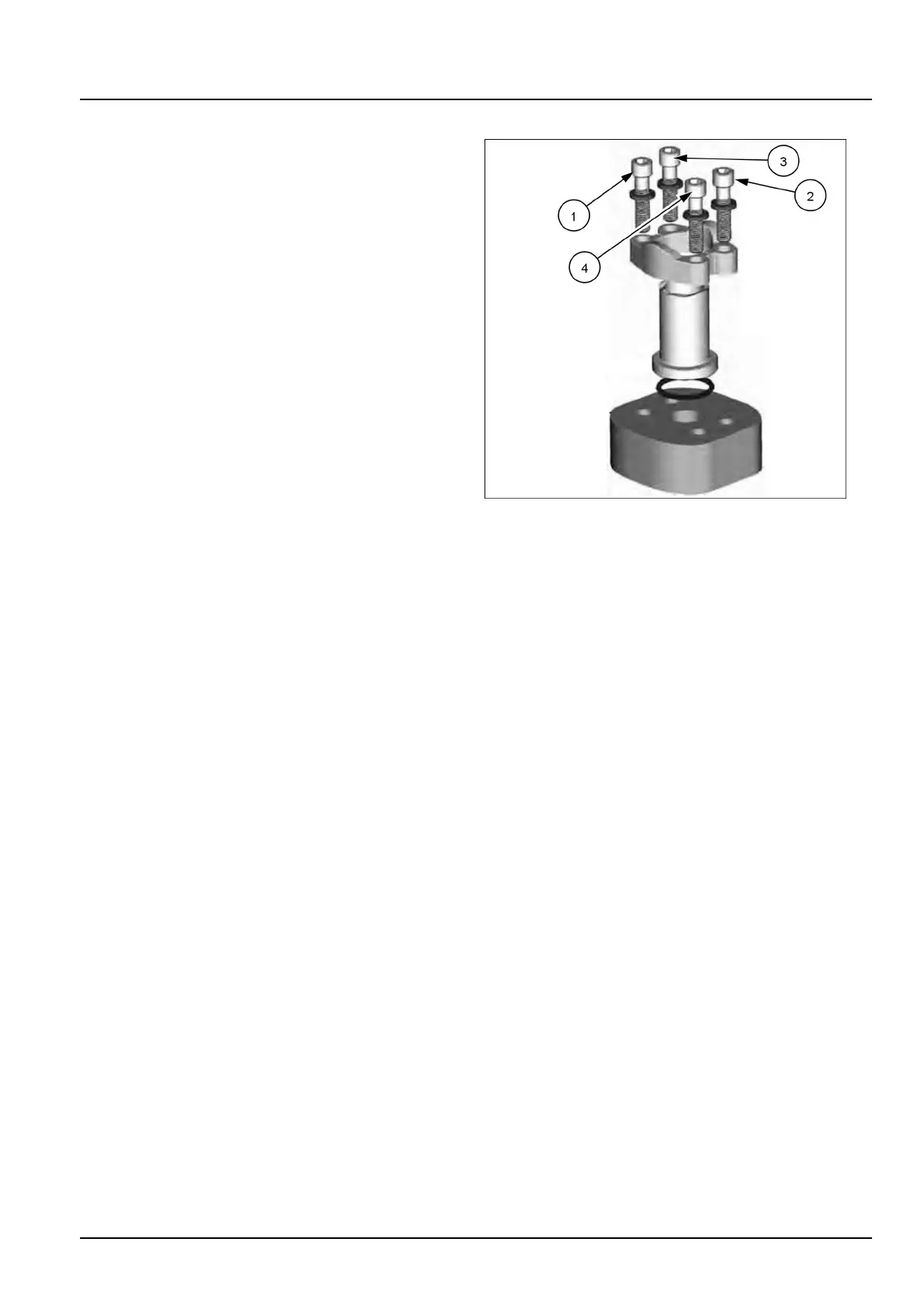

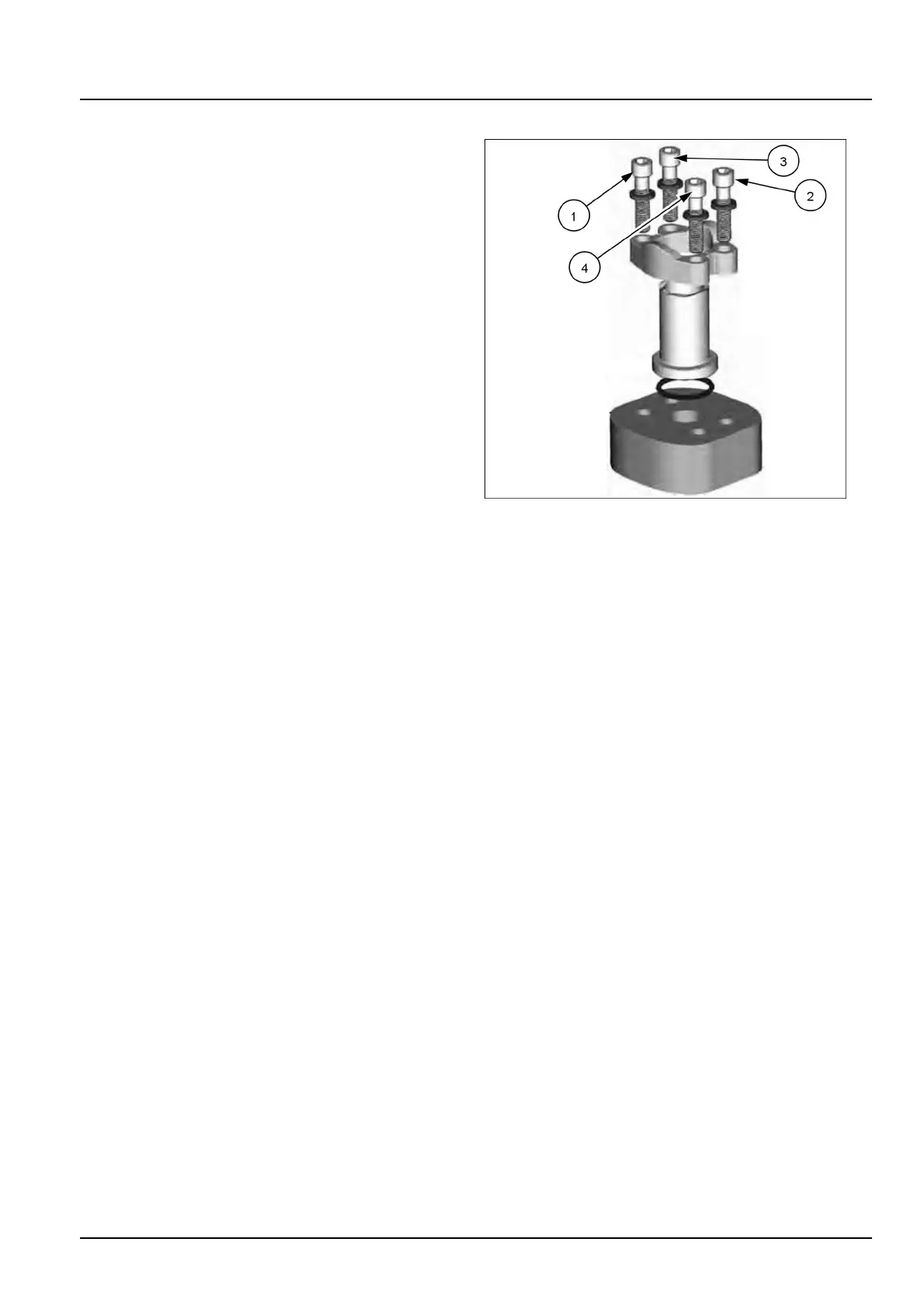

Installationofangeconnectors

Flangeconnectionstypicallyhavefourbolts,although

someangeconnectionsmayhavemoreorfewer.The

angeconnectorconsistsoffourmaincomponents:

•

Abody(angehead)

•

AnO-ring

•

One“captive”ortwo“split”angeclamps

•

Boltsandwashers

1.Removeprotectiveconnectorcapsonlyimmediately

priortoassembly.

2.Inspectthecomponentstoensurethatthemaleand

femaleportthreadsandsealingsurfacesarefreeof

burrs,nicks,andscratches,oranyforeignmaterial.

Donotuseifimpuritiesarefound.

3.PlacetheO-ringinthegroove,thegroovewillbe

eitherontheportsideortheangeside.

4.Assembletheangeheadandtheclamps.

5.Positionandholdtheangeassemblyovertheport.

6.Fingertightenthebolthardwareevenlyandina

crossingpattern.

7.Tightenthebolthardwareto60%ofthetorquevalue.

Usethesamecrossingpattern.Seethetorquetables

forthepropertorquevalue.

NOTE:ForbolthardwarethatisnotMetricClass8.8

and10.9orInchGrade8seethe“Torque-Minimum

tighteningtorquesfornormalassembly”Torque-

Minimumtighteningtorquesfornormalassembly

().

8.Tightenthebolthardware1and2to100%ofthe

torquevalue.

9.Tightenthebolthardware3and4to100%ofthe

torquevalue.

RAIL15TLB0611BA4

4808003331/01/2017

27

Loading...

Loading...