Introduction

This manual covers servicing the Kohler lOHP 241 Sand 12HP 301 S engines. There are

some minor differences between these engines such

as the bore and stroke. The difference

will be indicated in the manual when they appear. These engines are of the 4 cycle type,

splash oil lubrication, cast iron block

and electric starting.

1#/JOffTANT

REFER TO THE SPECIFICATIONS SECTION OF THIS MANUAL FOR

DIMENSIONS, TOLERANCES,ETC. WHEN SERVICING THIS ENGINE.

THESE DATA ARE NOT INCLUDED IN THIS SECTION.

CHECKING COMPRESSION PRESSURE

Should you receive a service complaint dealing with excessive oil consumption, loss of

power, hard starting, rough running or excessive smoke, check the compression pressure

and the crankcase vacuum.

1. Steam clean engine thoroughly.

2. Warm up engine to operating tempera-

ture.

3. Remove the spark plug and shut off

the fuel valve.

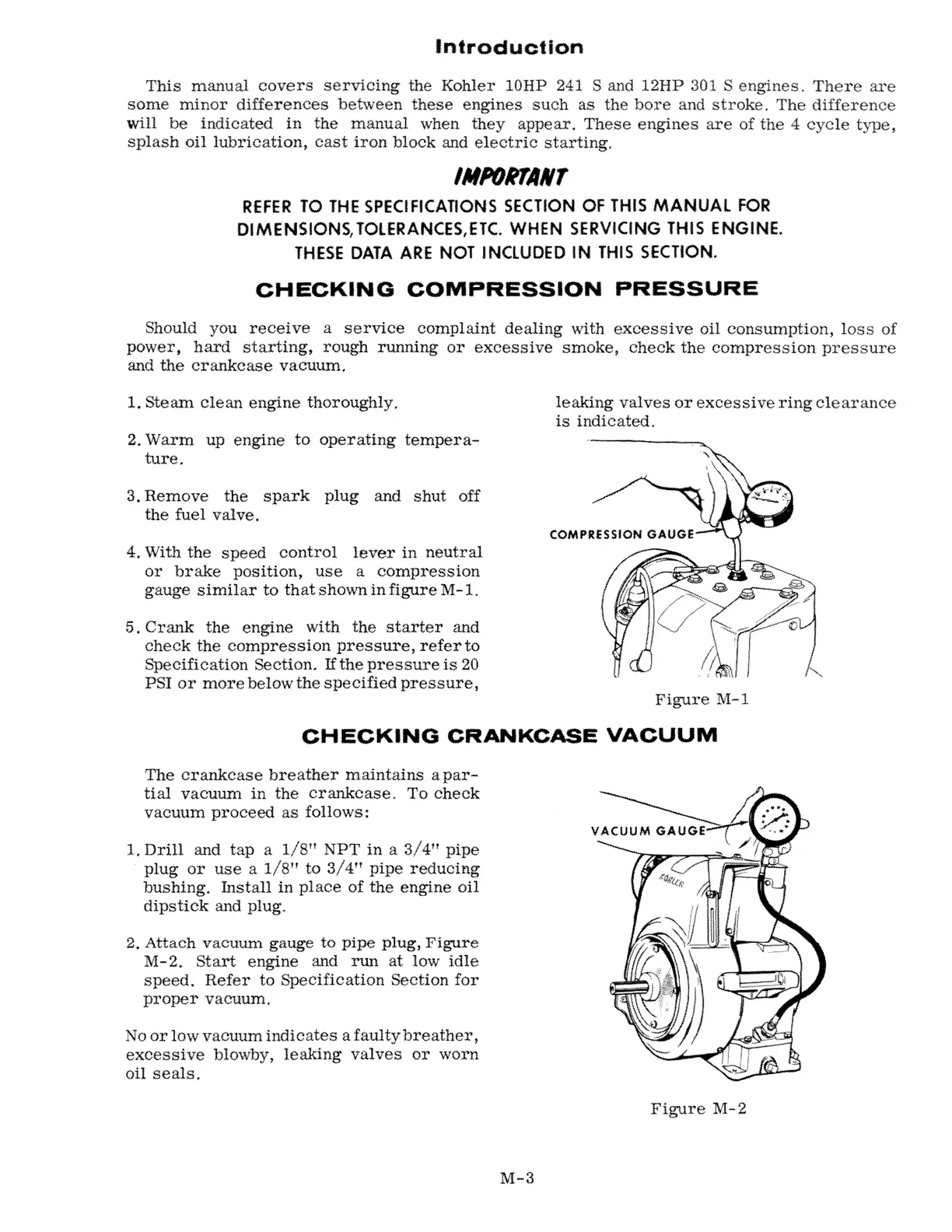

4. With the speed control lever in neutral

or brake position, use

a compression

gauge similar to thatshowninfigureM-1.

5. Crank the engine with the starter and

check the compression pressure, refer to

Specification Section.

If the pressure is 20

PSI or more below the specified pressure,

leaking valves or excessive ring clearance

is indicated.

Figure M-1

CHECKING CRANKCASE VACUUM

The crankcase breather maintains a par-

tial vacuum in the crankcase.

To check

vacuum proceed as follows:

1. Drill and tap a 1/8" NPT in a 3/4" pipe

plug or use a

1/8" to 3/4" pipe reducing

bushing. Install in place of the engine oil

dipstick and plug.

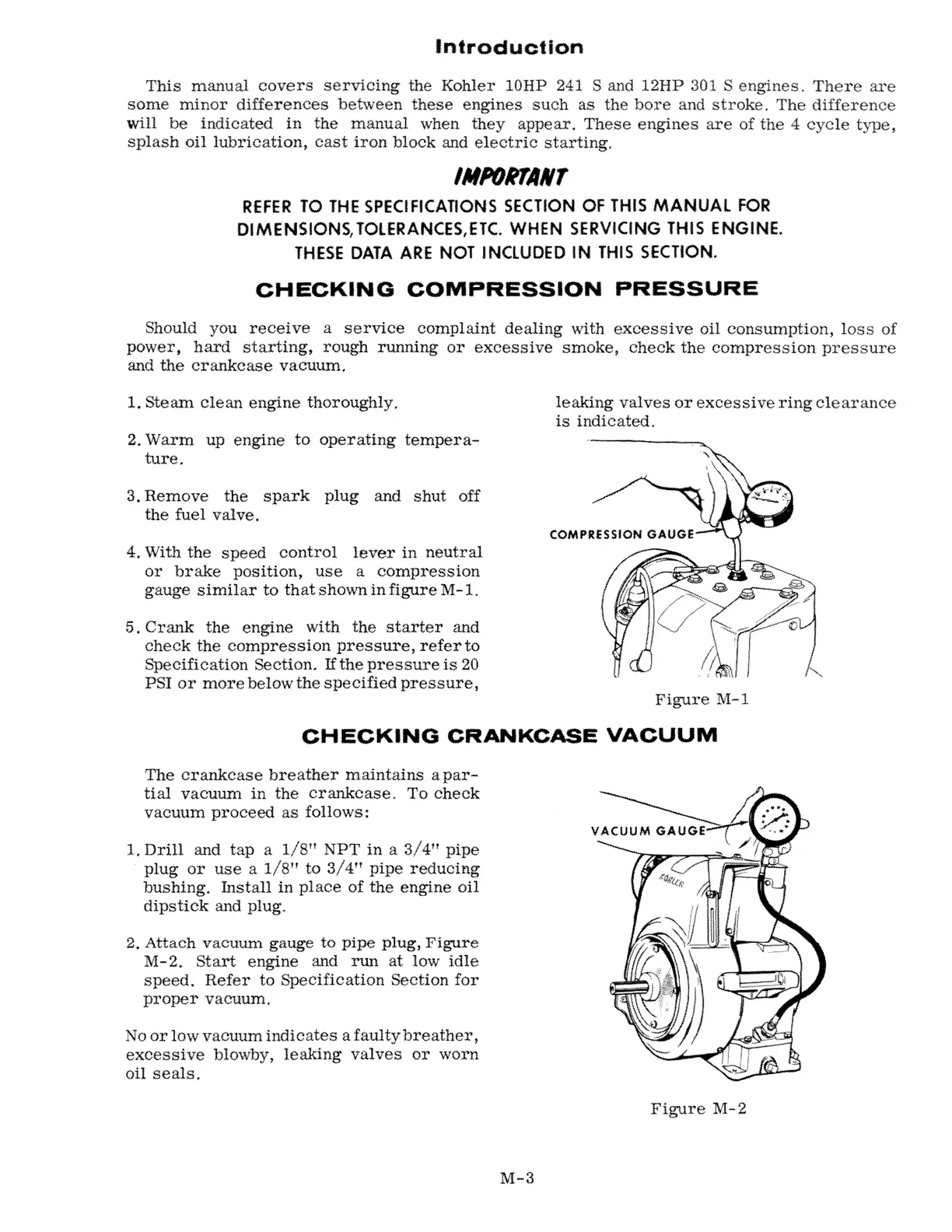

2. Attach vacuum

gauge to pipe plug, Figure

M-2. Start engine and

run at low idle

speed. Refer to Specification Section for

proper vacuum.

No or low vacuum indicates a faulty breather,

excessive blowby, leaking valves

or worn

oil seals.

Figure M-2

M-3

Loading...

Loading...