INSPECTION OP THE VALVES,OUIDES AND SPRINGS

Valve springs should be checked for flat

squared ends

t

broken or cracked coils and

correct spring p:ressure. Use a Valve Spring

Tension Tester. Refer to "Specification!!

Section.

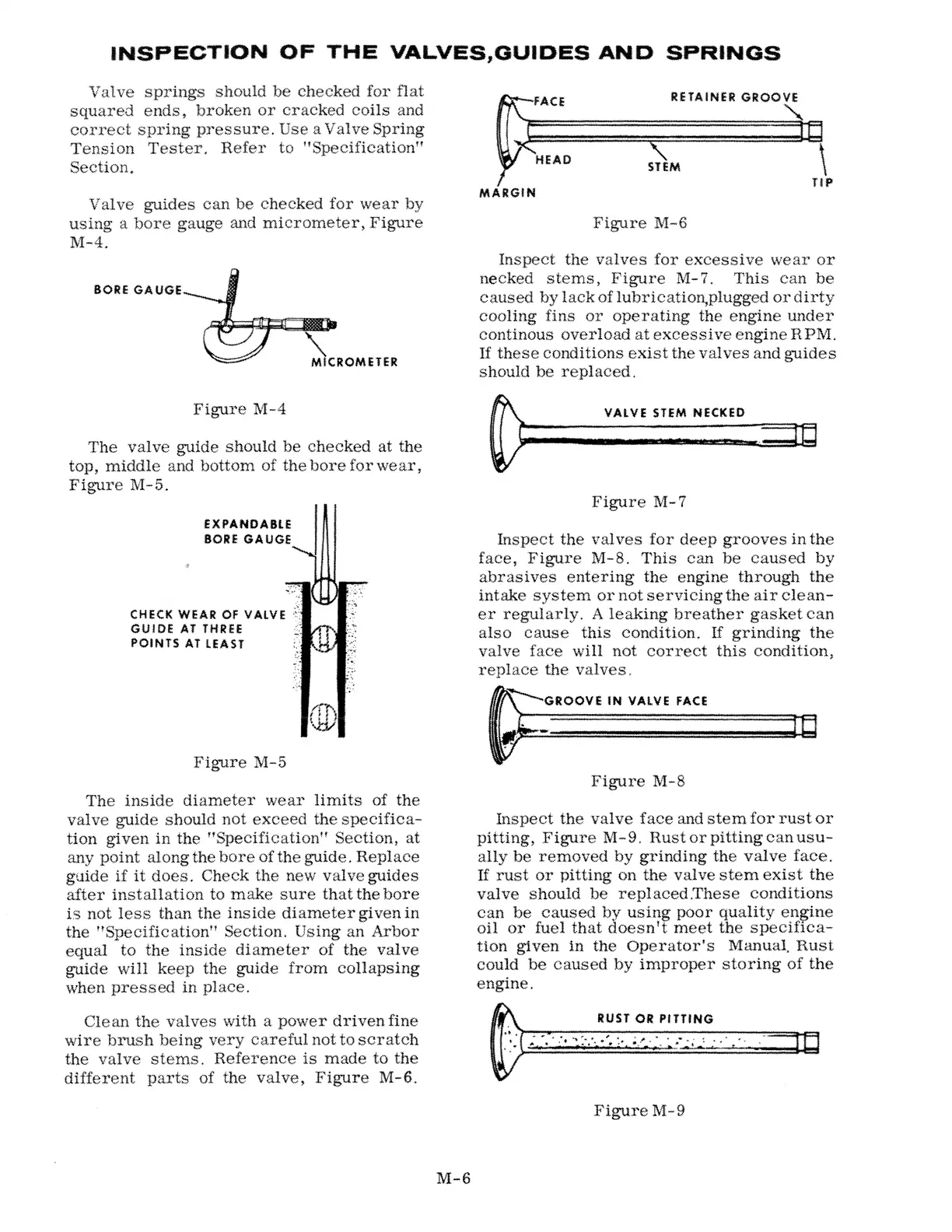

Valve guides can be checked for wear by

using a bore gauge and micrometer, Figure

M-4.

BORE GAUGE

Figure

M-4

The valve guide should be checked at the

top, middle and bottom of the bore for wear,

Figure M-5.

EXPANDABLE

BORE

GAUGE

CHECK WEAR OF VALVE :;:_

GUIDE AT

THREE

POINTS AT LEAST

Figure M-5

The inside diameter wear limits of the

valve guide should not exceed the specifica-

tion given in the "Specification" Section, at

any point along the bore of the guide, Replace

guide

if

it does. Check the new valve guides

after installation to make sure that the bore

is not less than the inside diameter given in

the "Specification" Section. Using an Arbor

equal to the inside diameter of the valve

guide will keep the guide from collapsing

when pressed in place.

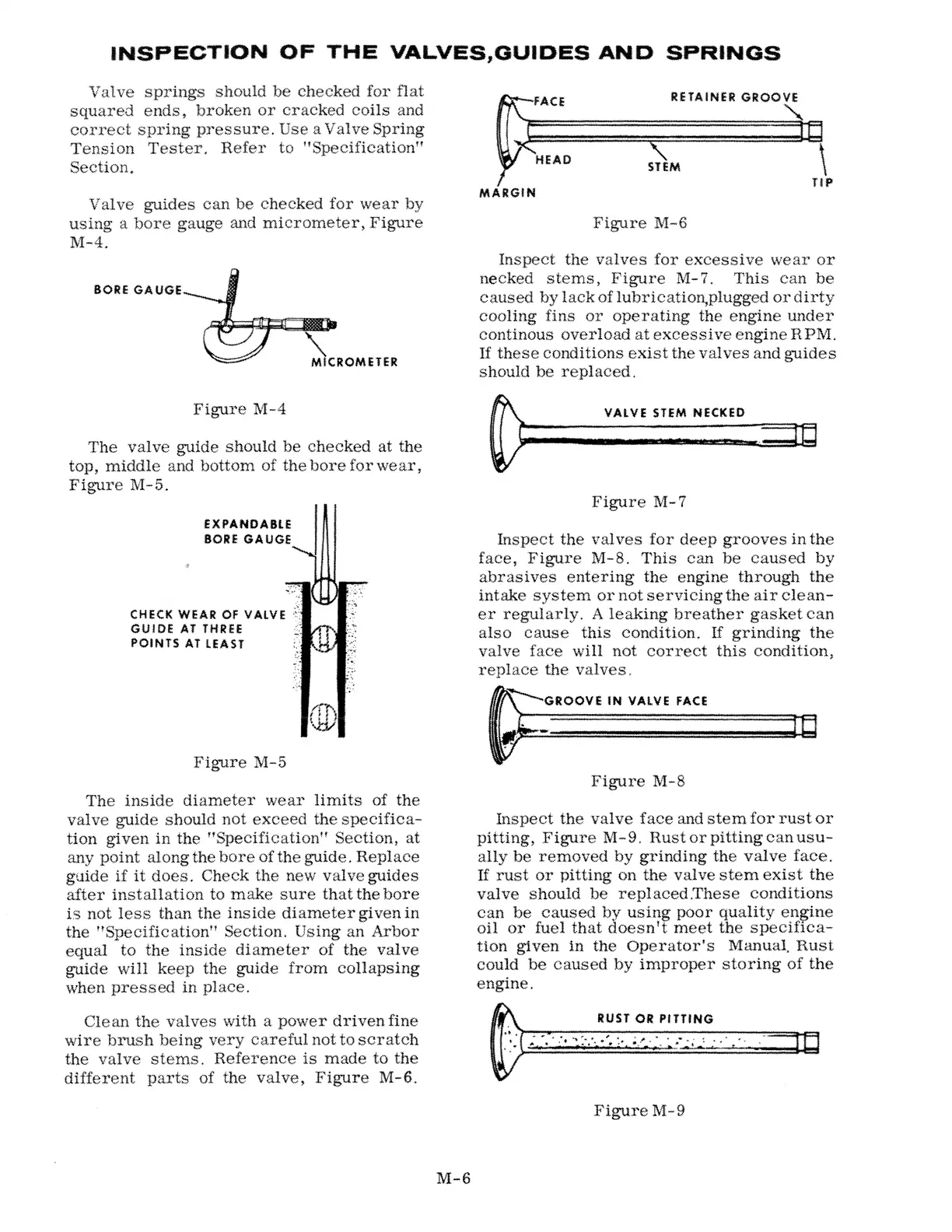

Clean the valves with a power driven fine

wire brush being very careful not to scratch

the valve stems. Reference is made to the

different parts of the valve, Figure M-6.

M-6

MARGIN

TIP

Figure M-6

Inspect the valves for excessive wear or

necked sterns, Figure

M-7.

This can be

caused by lack of lubrication,plugged or dirty

cooling fins or operating the engine under

continous overload at excessive engine RPM.

If these conditions exist the valves and guides

should be replaced.

VALVE STEM NECKED

Figure

M-7

Inspect the valves for deep grooves in the

face, Figure M-8. This can be caused by

abrasives entering the engine through the

intake system or not servicing the air clean-

er regularly. A leaking breather gasket can

also cause this condition.

If grinding the

valve face will not correct this condition,

replace the valves,

ROOVE

IN

VALVE FACE

Figure M-8

Inspect the valve face and stern for rust or

pitting, Figure M-9. Rustorpittingcanusu-

ally be removed by grinding the valve face.

If

rust or pitting on the valve stem exist the

valve should

be

replaced.These conditions

can

be

caused by using poor quality · ne

oil or fuel that doesn't meet the speci ca-

tion given in the Operator's Manual. Rust

could

be

caused

by

improper storing of the

engine.

RUST OR PITTING

Figu:reM-9

Loading...

Loading...