REFACING INTAKE AND EXHAUST VALVES

Before refacing the valves they should be

wire brushed, cleaned and inspected, Refer

to the

ti Specification" Section for the correct

valve face grinding angle. Set the refacing

machine protractor at this angle. Be sure

the chuck of the machine is clean before

installing valve. Dress the grinding wheel

before starting to each valve. Take

only light cuts as the valve is refaced and

the last cut must be very fine so the valve

face will have a polished finish.

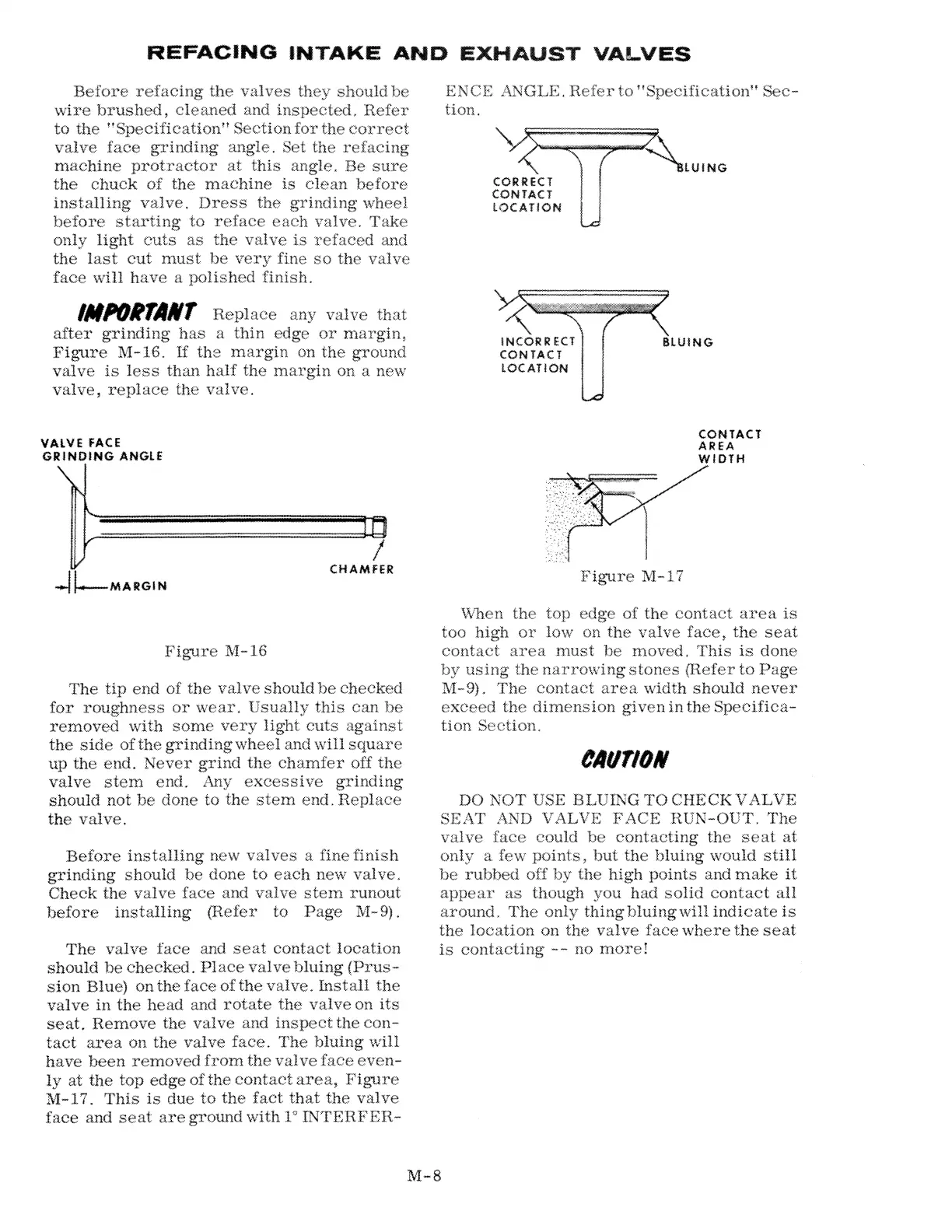

/#/IO/ITAIIT Replace any valve that

after grinding has a thin edge or margin,

Figure M-16. If the margin on the ground

valve is less than half the margin on a new

valve, replace the valve.

VALVE FACE

GRINDING ANGLE

-ll-MARGIN

Figure M-16

I

CHAMFER

The tip end of the valve should be checked

for roughness or wear. Usually this can be

removed with some very light cuts against

the side of the grinding wheel and will square

up the end. Never grind the chamfer off the

valve stem end.

Any excessive grinding

should not be done to the stem end. Replace

the valve.

Before installing new valves a fine finish

grinding should be done to each new valve.

Check the valve face and valve stem runout

before installing (Refer to Page M-9).

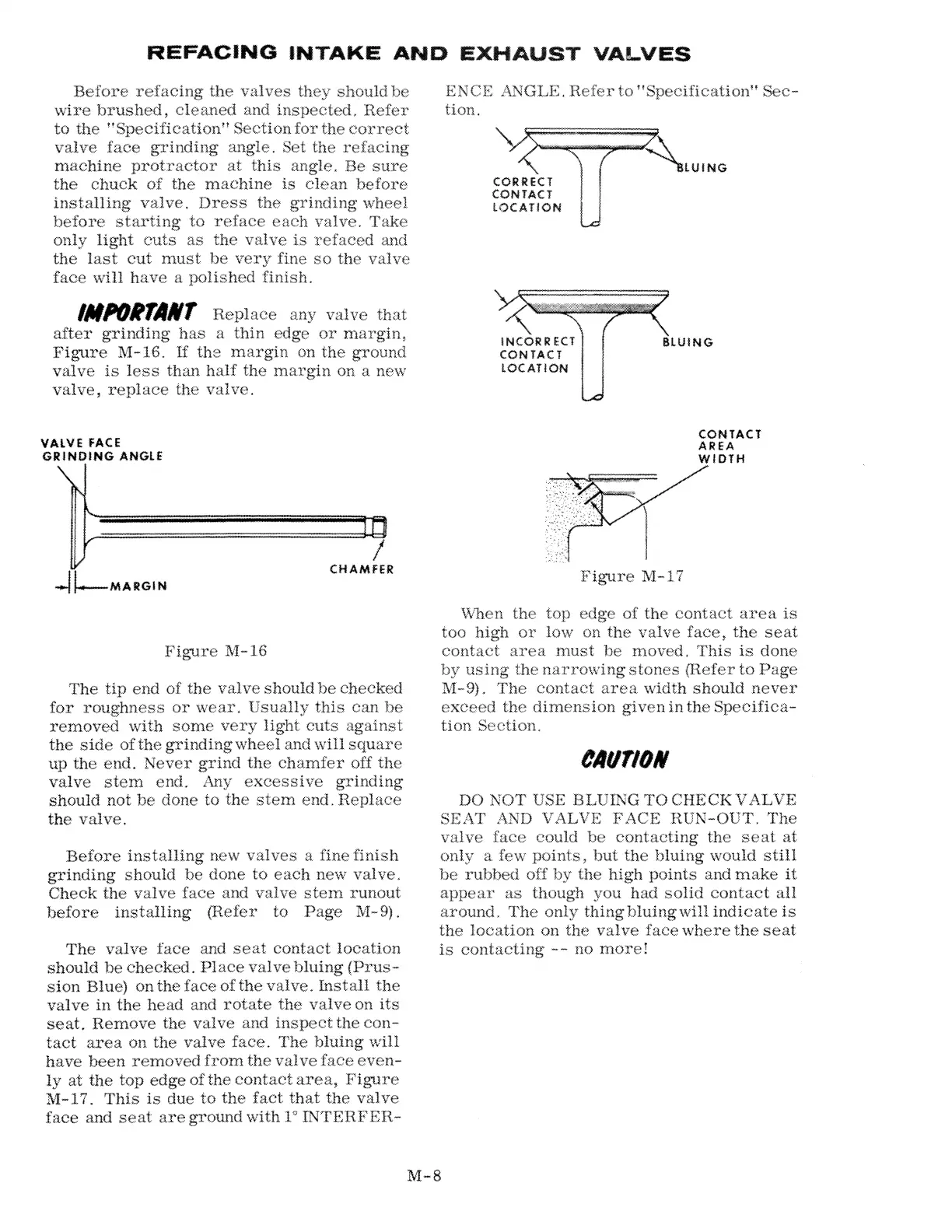

The valve face and seat contact location

should be checked. Place valve bluing (Prus-

sion Blue) on the face of the valve. Install the

valve in the head and rotate the valve on its

seat. Remove the valve and inspect the con-

tact area on the valve face. The bluing will

have been removed from the valve face even-

ly at the top edge of the contact area, Figure

M-1 7. This is due to the fact that the valve

face and seat are ground with

1" INTERFER-

ENCE ANGLE. Refer to "Specification" Sec-

tion.

CORRECT

CONTACT

LOCATION

INCORRECT

CONTACT

LOCATION

BLUING

Figure M-17

CONTACT

AREA

WIDTH

When the top edge of the contact area is

too high or low on the valve face, the seat

contact area must be moved. This is done

by using the narrowing stones (Refer to Page

M-9). The contact area width should never

exceed the dimension given in the Specifica-

tion Section.

CAUTION

DO NOT USE BLUINGTOCHECKVALVE

SEAT AND VALVE FACE RUN-OUT. The

valve face could be

contacting the seat at

only a few points, but the bluing would still

be rubbed off by the high points and make it

appear as though you had solid contact all

around. The only thing bluingwm indicate is

the location on the valve face where the seat

is contacting -- no morel

M-8

Loading...

Loading...