22-2

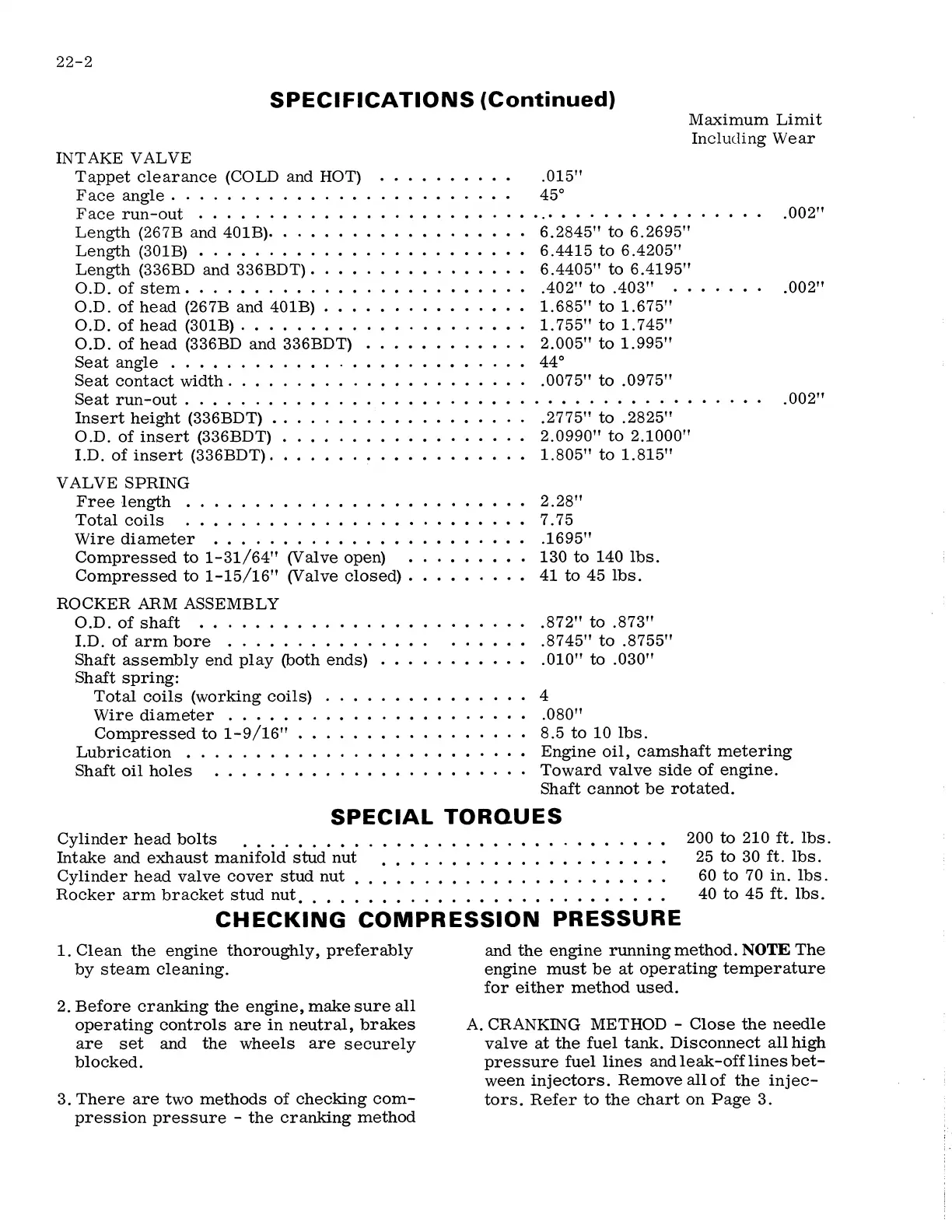

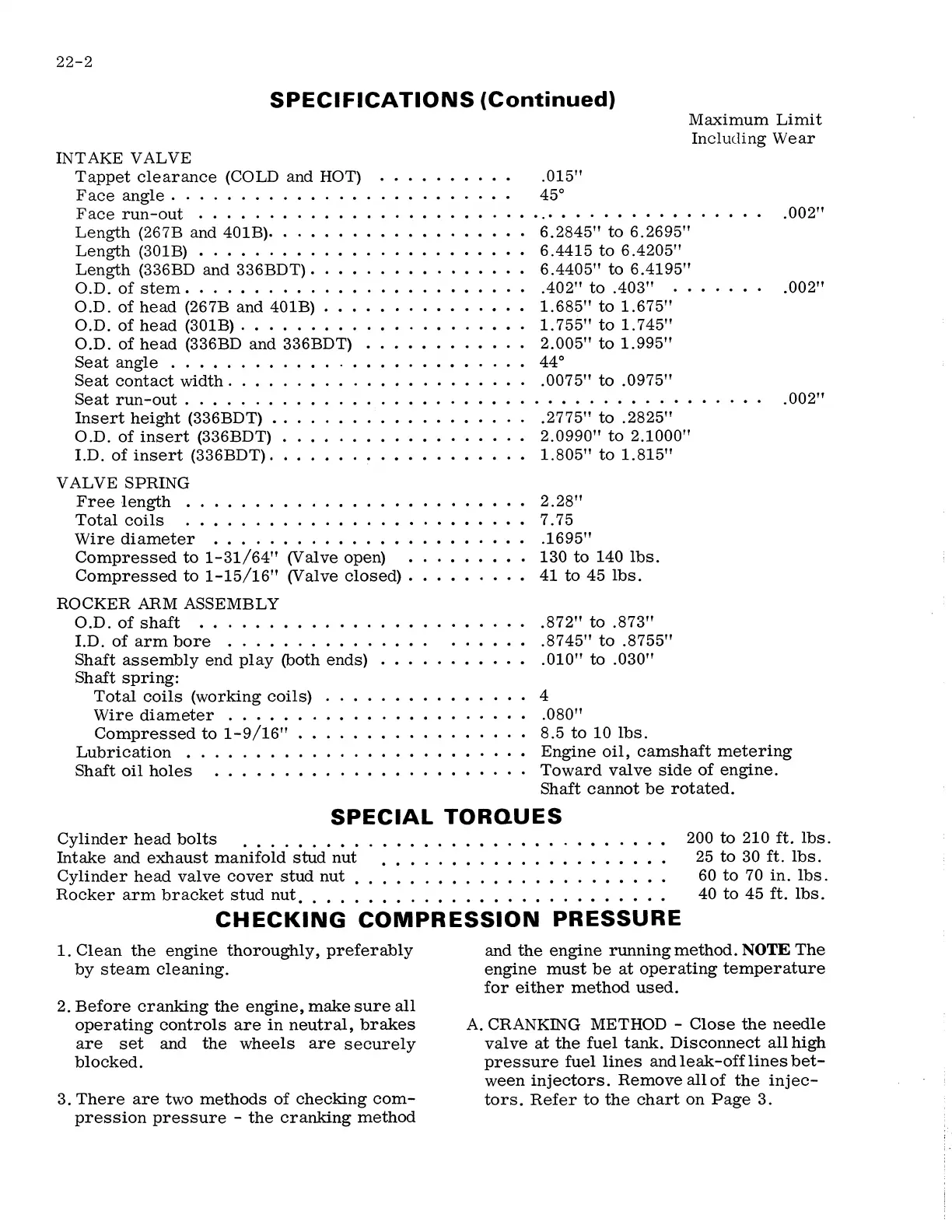

SPECIFICATIONS (Continued)

INTAKE VALVE

Tappet clearance (COLD and HOT)

Face angle ........ .

Face run -out . . . . . . .

Length (267B and 401B) ..

Length (301B) . . . . . . .

Length (336BD and 336BDT) .

O.D. of stem ......... .

O.D. of head (267B and 401B) .. .

O.D. of head (301B) .......... .

O.D. of head (336BD and 336BDT) ..

Seat angle ....... .

Seat contact width . . . . .

Seat run-out . . . . . . . . .

Insert height (336BDT) . . .

0 .D. of insert (336BDT)

I.D. of insert (336BDT).

VALVE SPRING

Free length ................ .

Total coils . . . . . . . . . . . . . . . . .

Wire diameter . . . . . . . . . . . . . . .

Compressed to 1-31/64" (Valve open) .

Compressed to 1-15/16" (Valve closed) .

ROCKER ARM ASSEMBLY

O.D. of shaft ............... .

I.D. of arm bore . . . . . . . . . . . . . .

Shaft assembly end play (both ends) .

Shaft spring:

Total coils (working coils) . .

Wire diameter . . . . . . .

Compressed to 1-9/16" ...

Lubrication . .

Shaft oil holes . . . . . . • . . . . . .

Maximum Limit

Including Wear

.015"

45°

.

.

. .

.

. . . . .

.

. .

.

.

. .

.

6.2845" to 6.2695"

6.4415 to 6.4205"

6.4405" to 6.4195"

.402" to .403" .

1.685" to 1.675"

1. 755" to 1. 745"

2.005" to 1.995"

44°

.0075" to .0975"

.2775" to .2825"

2.0990" to 2.1000"

1.805" to 1.815"

2.28"

7.75

.1695"

130 to 140 lbs.

41 to 45 lbs.

.872" to .873"

.8745" to .8755"

.010"

to

.030"

4

.080"

8.5 to 10 lbs.

.002"

.002"

.002"

Engine oil, camshaft metering

Toward valve side of engine.

Shaft cannot be rotated.

SPECIAL TORQUES

Cylinder head bolts ..... .

Intake and exhaust manifold stud nut

Cylinder head valve cover stud nut .

Rocker arm bracket stud nut. . • . .

200

to

210 ft. lbs.

25 to 30 ft. lbs.

60 to 70 in. lbs.

40 to 45 ft. lbs.

CHECKING COMPRESSION PRESSURE

1. Clean the engine thoroughly, preferably

by steam cleaning.

2. Before cranking the engine, make sure all

operating controls are in neutral, brakes

are set and the wheels are securely

blocked.

3. There are two methods of checking com-

pression pressure - the cranking method

and the engine running method.

NOTE

The

engine must be at operating temperature

for either method used.

A. CRANKING METHOD - Close the needle

valve at the fuel tank. Disconnect all high

pressure fuel lines and leak-offlines bet-

ween injectors. Remove all of the injec-

tors. Refer to the chart on Page 3.

Loading...

Loading...