22-3

CHECKING COMPRESSION PRESSURE (Continued)

B. RUNNING METHOD - Disconnect the

high pressure fuel line and leak-off lines

from number one injector. Using an

appropriate length of tubing or hose,

route the fuel from these lines back to

the fuel tank or a clean container. Re-

move the number one injector. Refer to

chart below.

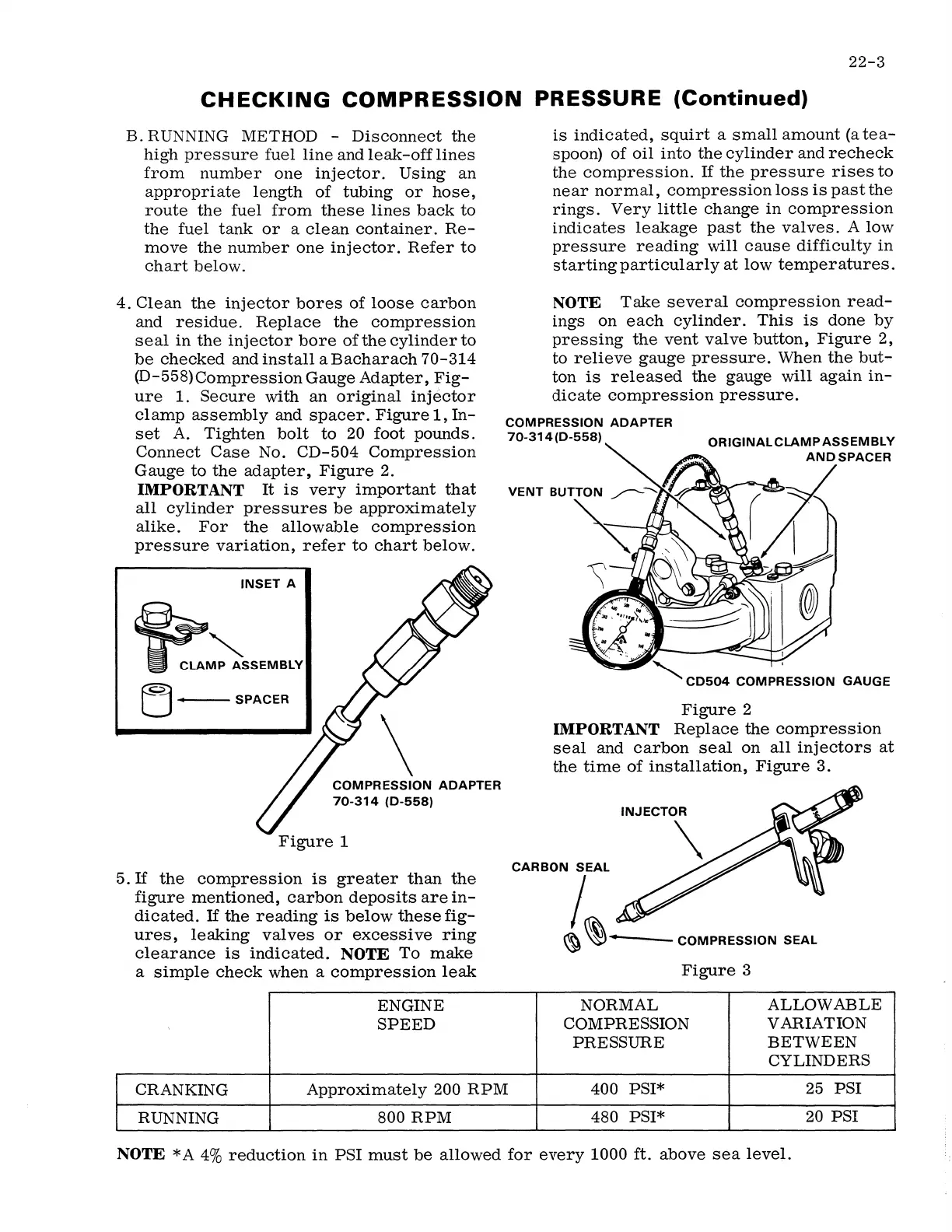

4. Clean the injector bores of loose carbon

and residue. Replace the compression

seal in the injector bore of the cylinder to

be checked and install a Bacharach 70-314

(D-558) Compression Gauge Adapter, Fig-

ure

1. Secure with an original injector

clamp assembly and spacer. Figure 1, In-

set A. Tighten bolt to 20 foot pounds.

Connect Case No. CD-504 Compression

Gauge to the adapter, Figure 2.

IMPORTANT It is very important that

all cylinder pressures be approximately

alike. For the allowable compression

pressure variation, refer to chart below.

INSET A

i!:~SEMBLV

~-

LJ SPACER

COMPRESSION ADAPTER

70-314 (D-558)

5. If the compression is greater than the

figure mentioned, carbon deposits are in-

dicated.

If the reading is below these fig-

ures, leaking valves or excessive ring

clearance is indicated.

NOTE To make

a simple check when a compression leak

ENGINE

'

SPEED

is indicated, squirt a small amount (a tea-

spoon) of oil into the cylinder and recheck

the compression.

If the pressure rises to

near normal, compression loss is past the

rings. Very little change in compression

indicates leakage past the valves. A low

pressure reading will cause difficulty in

starting particularly at low temperatures.

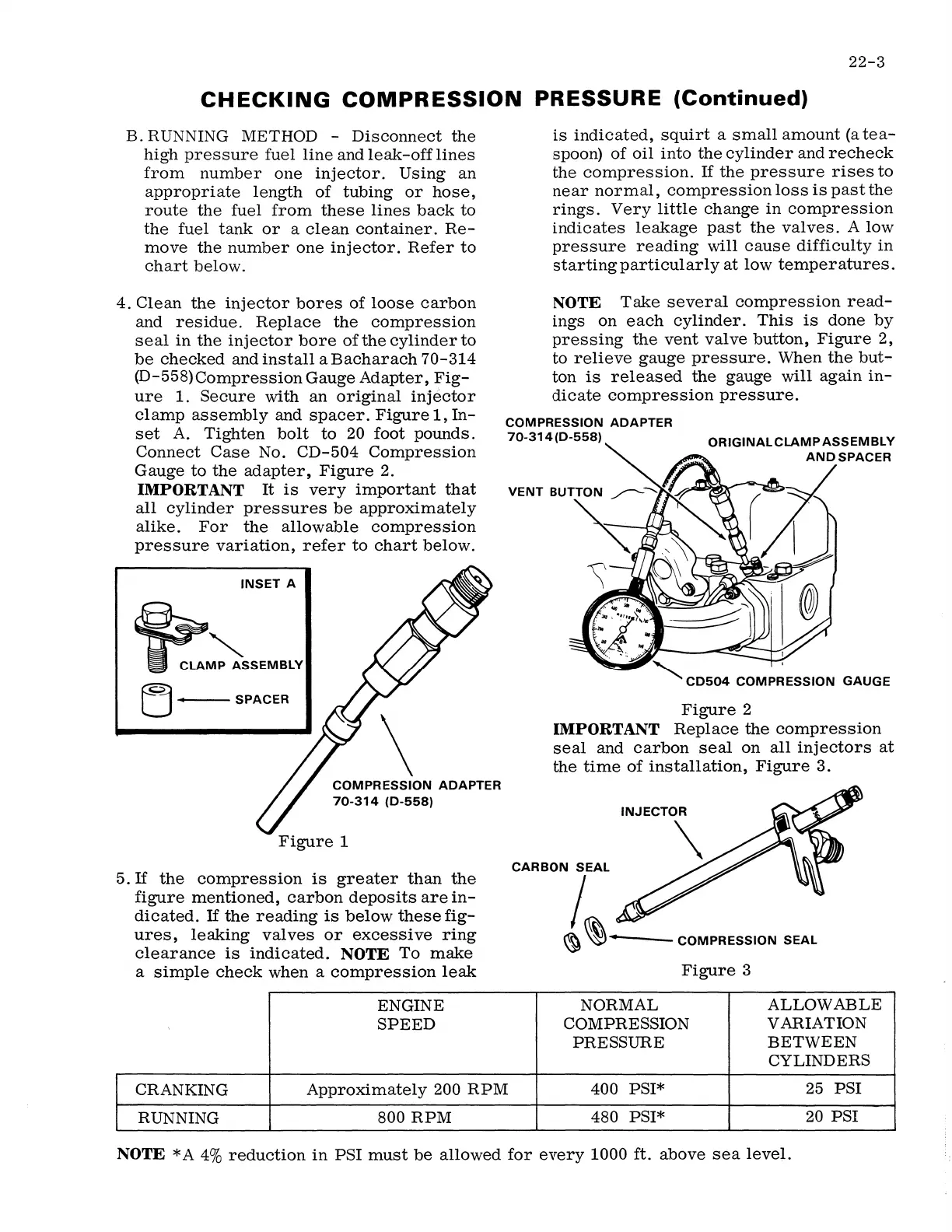

NOTE Take several compression read-

ings on each cylinder. This is done by

pressing the vent valve button, Figure 2,

to relieve gauge pressure. When the but-

ton is released the gauge will again in-

dicate compression pressure.

COMPRESSION ADAPTER

70-314 (D-558)

IGINALCLAMPASSEMBLY

AND SPACER

VENT BUTTON

I

I

"CD504 COMP~ESSION GAUGE

Figure 2

IMPORTANT Replace the compression

seal and carbon seal on all injectors at

the time of installation, Figure 3.

CARBON SEAL

L 1--- COMPRESSION SEAL

Figure 3

NORMAL

ALLOWABLE

COMPRESSION

VARIATION

PRESSURE

BETWEEN

CYLINDERS

CRANKING

Approximately 200 RPM 400 PSI*

25 PSI

RUNNING

800 RPM

480 PSI*

20 PSI

NOTE *A 4% reduction in PSI must be allowed for every 1000 ft. above sea level.

Loading...

Loading...