22-21

INSPECTION OF VALVES, GUIDES, HEAD AND SPRINGS (Contd)

Heavy carbon or varnish deposits on the

valves, Figure 19, should be removed before

valves are ground. This condition is usually

caused by worn piston rings and sleeves

which allow too much oil to reach the com-

bustion chamber. This condition could also

be caused by worn valve guides or bad seals

on the valves. Lowoperatingtemperatureis

still another cause.

HEAVY CARBON AND VARNISH DEPOSITS

Inspect the valve head for dishing and the

valve face for deep burned spots, Figure 20.

These conditions cannot be corrected by

grinding the valves. The valves must be re-

placed. These conditions are usually caused

by running the engine under excessive loads

at high engine temperatures.

DEEP BURNED VALVE FACE DISHED VALVE HEAD

Figure 20

Valves with worn keeper groves or if the

stem tip is worn or dished beyond the

chamfer, replace the valves, Figure 21.

WORN RETAINER GROOVE WORN STEM TIP

Figure 21

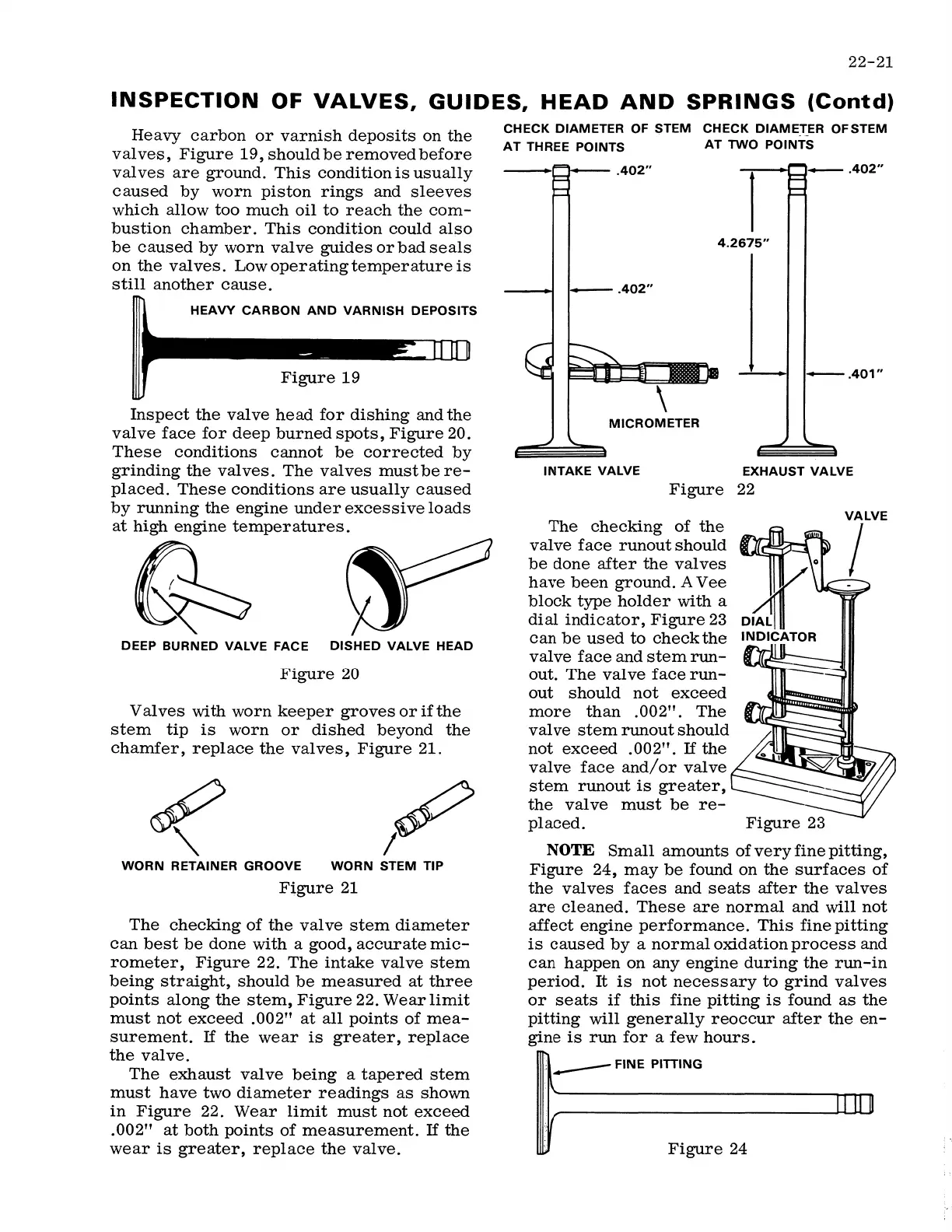

The checking of the valve stem diameter

can best be done with a good, accurate mic-

rometer, Figure 22. The intake valve stem

being straight, should be measured at three

points along the stem, Figure 22. Wear limit

must not exceed .002" at all points of mea-

surement.

If the wear is greater, replace

the valve.

The exhaust valve being a tapered stem

must have two diameter readings as shown

in Figure 22. Wear limit must not exceed

.002" at both points of measurement.

If the

wear is greater, replace the valve.

CHECK DIAMETER OF STEM CHECK DIAMEJ:.ER OFSTEM

AT THREE POINTS AT TWO POINTS

--•F.--- .402"

--r-

♦

c:::-::1-

.402"

l

a:::

t:::

4.2675"

.402"

-.401"

MICROMETER

INTAKE VALVE

EXHAUST VALVE

Figure 22

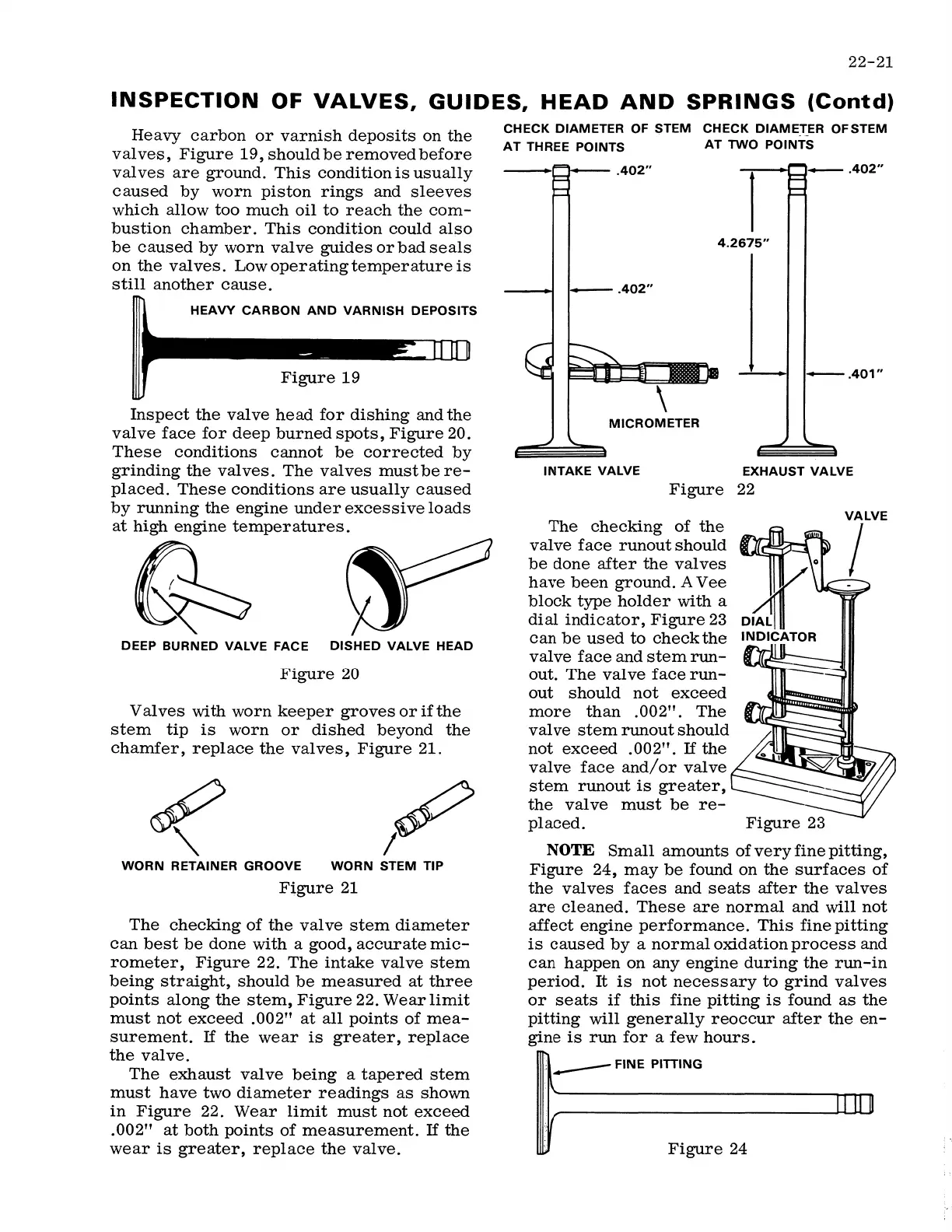

The checking of the

valve face runout should

be done after the valves

have been ground. A Yee

block type holder with a

dial indicator, Figure 23

can be used to check the

valve face and stem run-

out. The valve face run-

out should not exceed

more than .002". The

valve stem runout should

not exceed .002".

If the

valve face and/or valve

stem runout is greater,

the valve must be re-

placed.

NOTE Small amounts ofveryfinepitting,

Figure 24, may be found on the surfaces of

the valves faces and seats after the valves

are cleaned. These are normal and will not

affect engine performance. This fine pitting

is caused by a normal oxidation process and

can happen on any engine during the run-in

period. It is not necessary to grind valves

or seats if this fine pitting is found as the

pitting will generally reoccur after the en-

gine is run for a few hours.

: --- FINE PITTING

Figure 24

Loading...

Loading...