22-22

REFACING INTAKE AND EXHAUST VALVES

Before refacing the valves, they should be

wire brushed, cleaned and inspected. A 45°

angle is the correct valve face grinding

angle. Set the refacing machine protractor

at this angle. Be sure the chuck of the mach-

ine is clean before installing the valve.

Dress the grinding wheel before starting to

reface the valves. Take only light cuts as

the valve is refaced. The last cut must be

very fine so the valve face will have a pol-

ished finish.

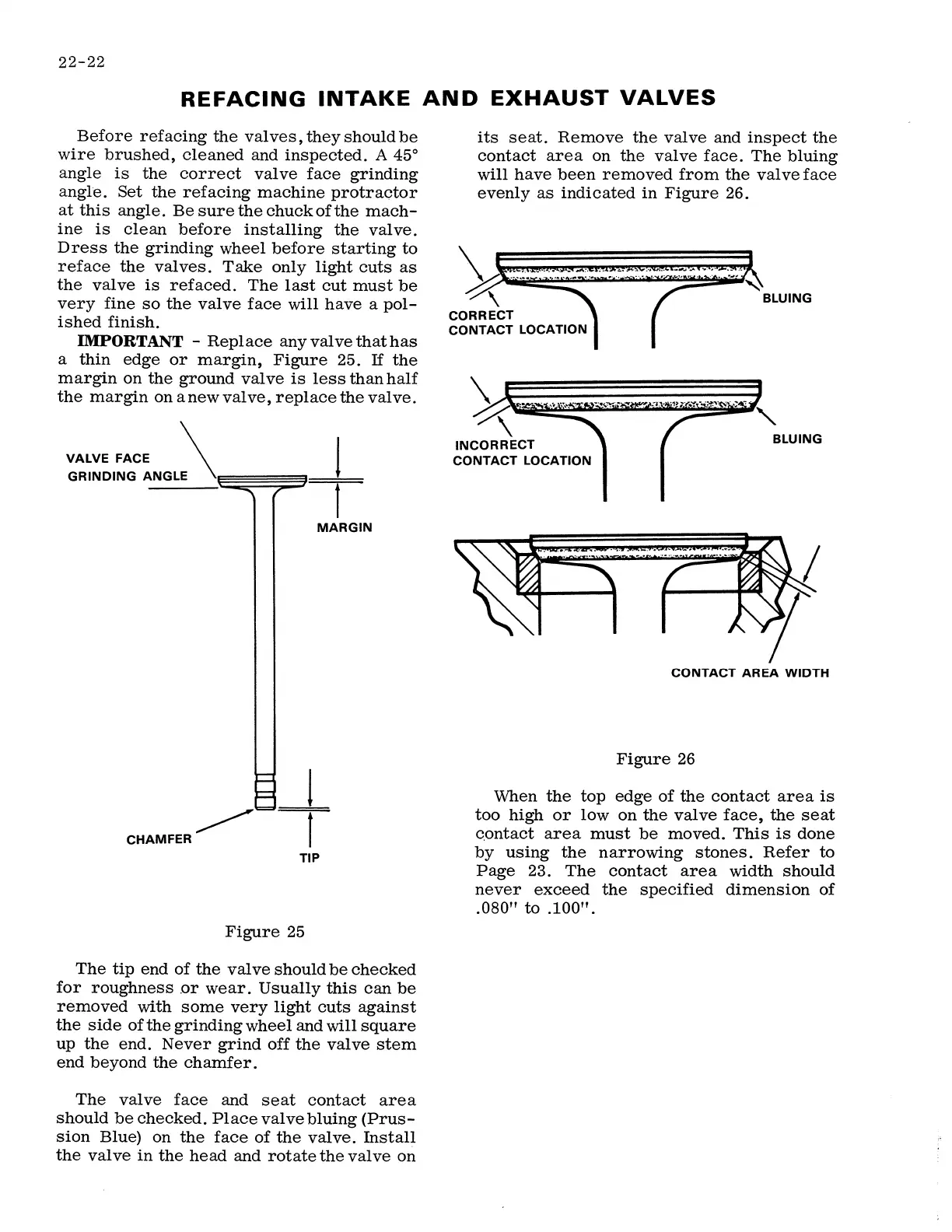

IMPORTANT -

Replace anyvalvethathas

a thin edge or margin, Figure

25.

If

the

margin on the ground valve is less than half

the margin on anew valve, replace the valve.

VALVE FACE \

l

GRINDING A~N~G~L=E~_):~~~~,===,:=

T

MARGIN

1

~

CHAMFER

l

TIP

Figure 25

The tip end of the valve should be checked

for roughness .or wear. Usually this can be

removed with some very light cuts against

the side of the grinding wheel and will square

up the end. Never grind off the valve stem

end beyond the chamfer.

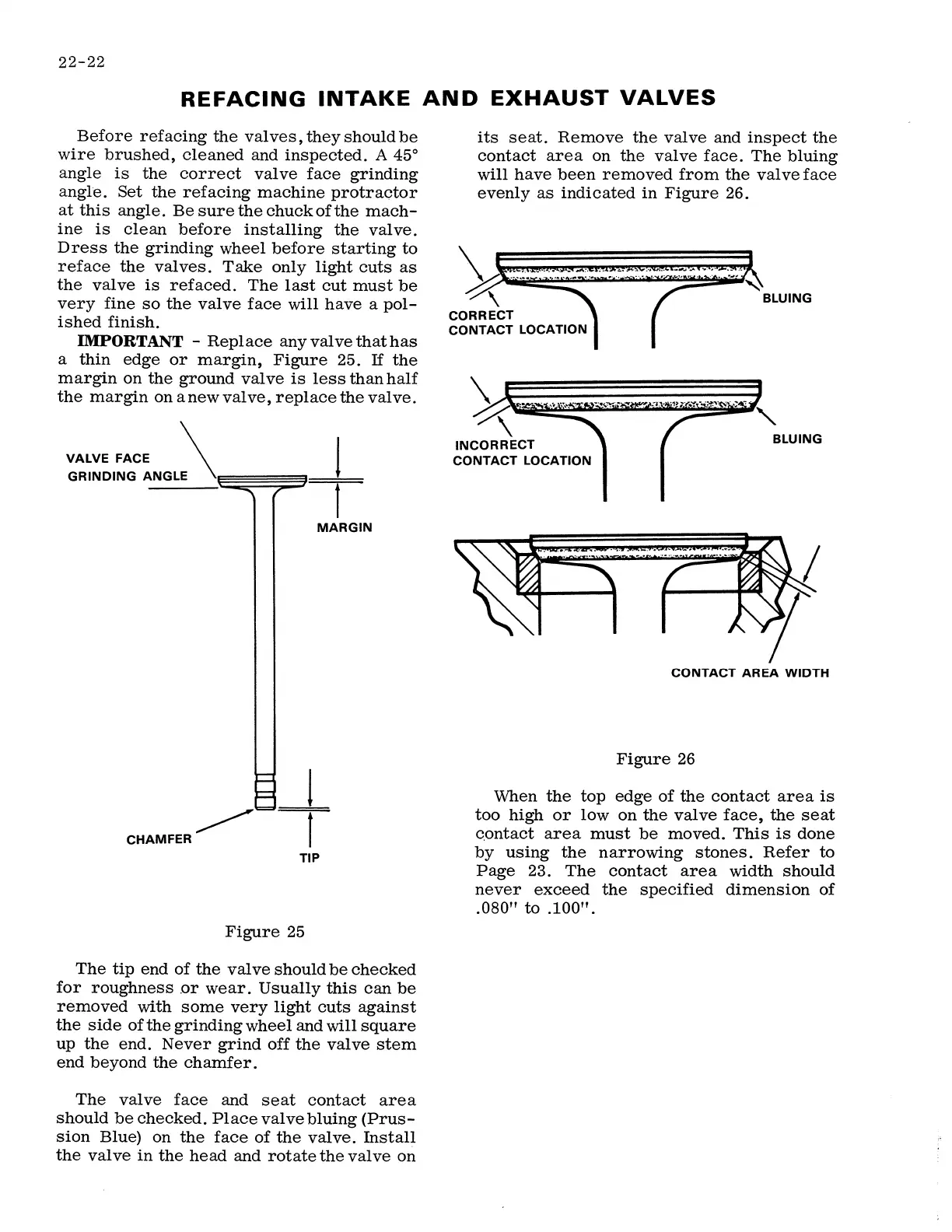

The valve face and seat contact area

should be checked. Place valve bluing (Prus-

sion Blue) on the face of the valve. Install

the valve in the head and rotate the valve on

its seat. Remove the valve and inspect the

contact area on the valve face. The bluing

will have been removed from the valve face

evenly as indicated in Figure

26.

\

CORRECT

CONTACT LOCATION

\ £=====-==-=-==-=-=_

=_ =_=_=I__,,,

\

INCORRECT

CONTACT LOCATION

BLUING

CONTACT AREA WIDTH

Figure

26

When the top edge of the contact area is

too high or low on the valve face, the seat

c.ontact area must be moved. This is done

by using the narrowing stones. Refer to

Page

23.

The contact area width should

never exceed the specified dimension of

.080"

to .100".

Loading...

Loading...