8. MACHINE LIFTING PROCEDURE

■

LIFTING PROCEDURES FOR THE MACHINE

COMPLETE

lb WARNING lb

• The wire ropes to be used for lifting the ma-

chine should have sufficient strength against

the machine weight.

• Improper lifting method and/or rope rigging

manner might cause for a movement or slip

of the machine while it is being lifted, result-

ing serious injury or damages to the machine.

• Do not impose a load suddenly on the wire

ropes and slings.

• When the lifting work is carried out in coop-

eration with multiple persons, make sure to

check every situation by exchanging signals

with each other.

• During the lifting work, keep any persons

away from the lifted machine, especially un-

der the machine

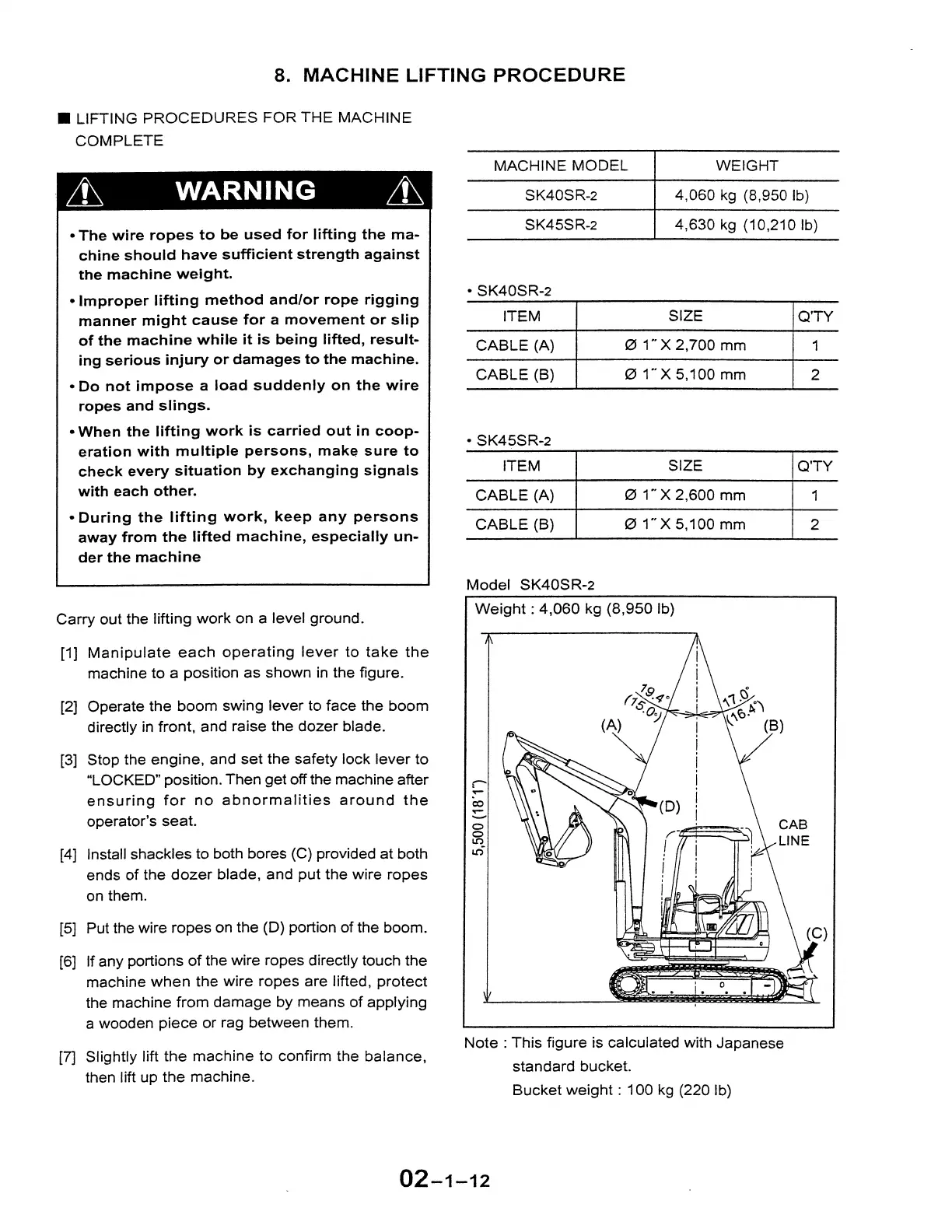

Carry out the lifting work on a level ground.

[1] Manipulate each operating lever to take the

machine to a position as shown in the figure.

[2] Operate the boom swing lever to face the boom

directly in front, and raise the dozer blade.

[3] Stop the engine, and set the safety lock lever to

"LOCKED" position. Then get off the machine after

ensuring for no abnormalities around the

operator's seat.

[4] Install shackles to both bores (C) provided at both

ends of the dozer blade, and put the wire ropes

on them.

[5] Put the wire ropes on the (D) portion of the boom.

[6] If any portions of the wire ropes directly touch the

machine when the wire ropes are lifted, protect

the machine from damage by means of applying

a wooden piece or rag between them.

[7] Slightly lift the machine to confirm the balance,

then lift up the machine.

MACHINE MODEL WEIGHT

SK40SR-2 4,060 kg (8,950 lb)

SK45SR-2 4,630 kg (10,210 lb)

• SK40SR-2

ITEM

SIZE

CABLE (A)

0 1" X 2,700 mm

CABLE (B)

0 1 .. X 5,100 mm

• SK45SR-2

ITEM

SIZE

CABLE (A)

0 1 .. X 2,600 mm

CABLE (B}

0 1"X 5,100 mm

Model SK40SR-2

Weight : 4,060 kg (8,950 lb)

Note : This figure is calculated with Japanese

standard bucket.

Bucket weight : 100 kg (220 lb)

Q'TY

1

2

Q'TY

1

2

02-1-12

Loading...

Loading...