INTRODUCTION

Torque

Bolttypes

NOTICE:Usetoolsappropriatefortheworktobedone.

Makeshifttoolsandprocedurescancreatesafetyhaz-

ards.Forlooseningandtighteningnutsandbolts,use

thecorrecttools.Avoidbodilyinjurycausedbyslipping

wrenches.

TULI12ECX0475AA1

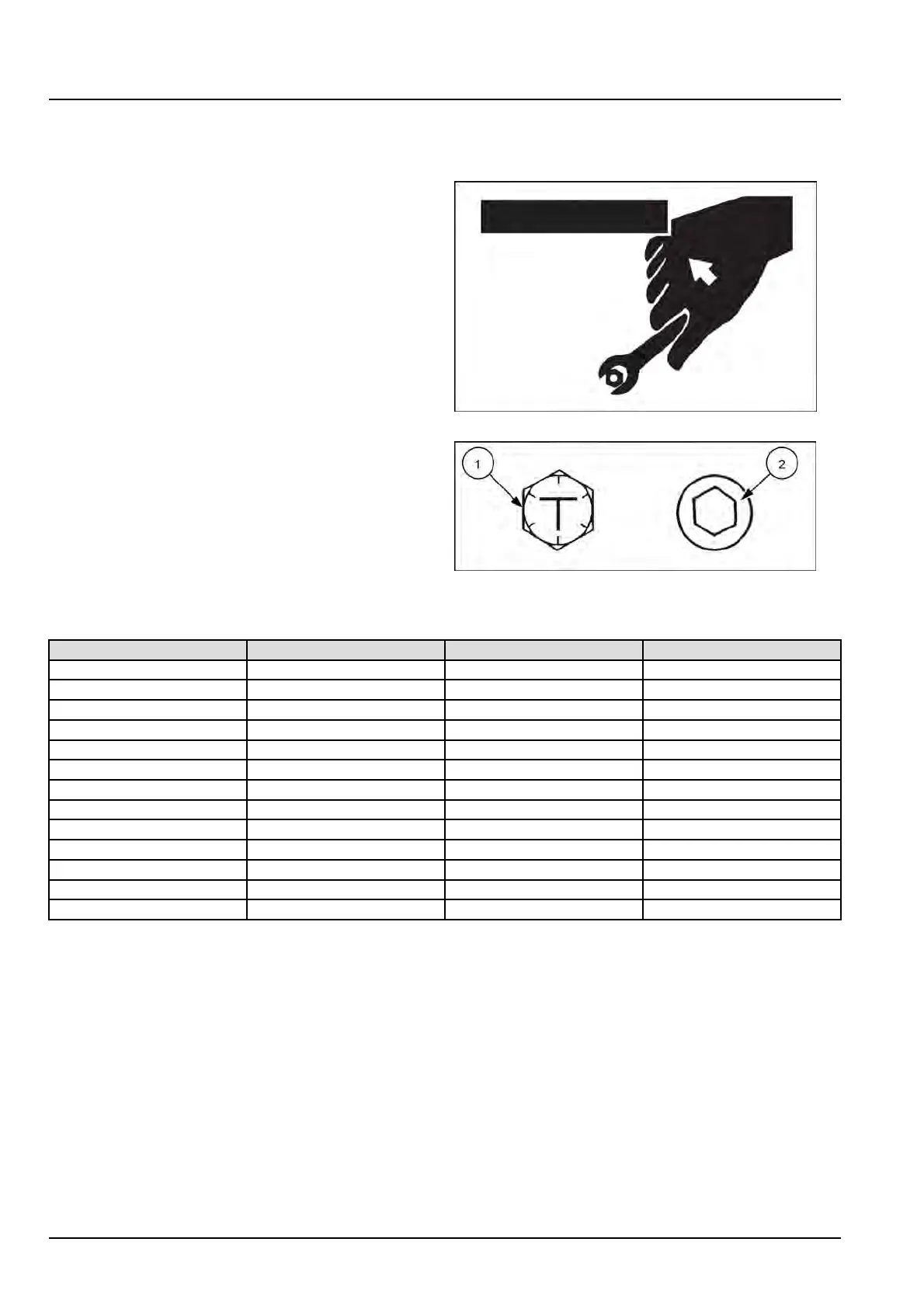

Tightennutsorboltstotorquespecications.Thereare

twokindsofbolts;hexagonTbolts(1)andsocketbolts

(2).Thetwotypesofboltsaremadefromdifferentmate-

rials.Thecorrecttypeofboltmustbeusedwhenassem-

blingthemachineand/orcomponents.

RAPH12CEX1320AA2

Speciedtighteningtorquechart

Boltdia.

WrenchsizeHexagonwrenchsizeTbolt,socketbolt

M813mm6mm

29.5N·m(22lbft)

M1017mm8mm

64N·m(47lbft)

M1219mm10mm

108N·m(80lbft)

M1422mm12mm

175N·m(129lbft)

M1624mm14mm

265N·m(195lbft)

M1827mm14mm

390N·m(288lbft)

M2030mm17mm

540N·m(398lbft)

M2232mm17mm

740N·m(546lbft)

M2436mm19mm

930N·m(686lbft)

M2741mm19mm

1370N·m(1010lbft)

M3046mm22mm

1910N·m(1409lbft)

M3350mm24mm

2550N·m(1881lbft)

M36

55mm

27mm

3140N·m(2316lbft)

1.Applylubricant(i.e.whitezincBdissolvedintospindleoil)tonutsandboltstostabilizetheirfrictioncoefcients.

2.Torquetoleranceis±10%.

3.Besuretouseboltsofcorrectlength.Boltsthataretoolongcannotbetightened,asthebolttipcomesintocontact

withthebottomofthebolthole.Boltsthataretooshortcannotdevelopsufcienttighteningforce.

4.Thetorquesgiveninthechartareforgeneraluseonly.

Donotusethesetorquesifadifferenttorqueisgivenforaspecicapplication.

5.Makesurethatthenutandboltthreadsarecleanbeforeinstalling.Removedirtorcorrosion,ifany.

4800537027/04/2016

14

Loading...

Loading...