76

Maintenance Section

Engine Oil Sample - Obtain

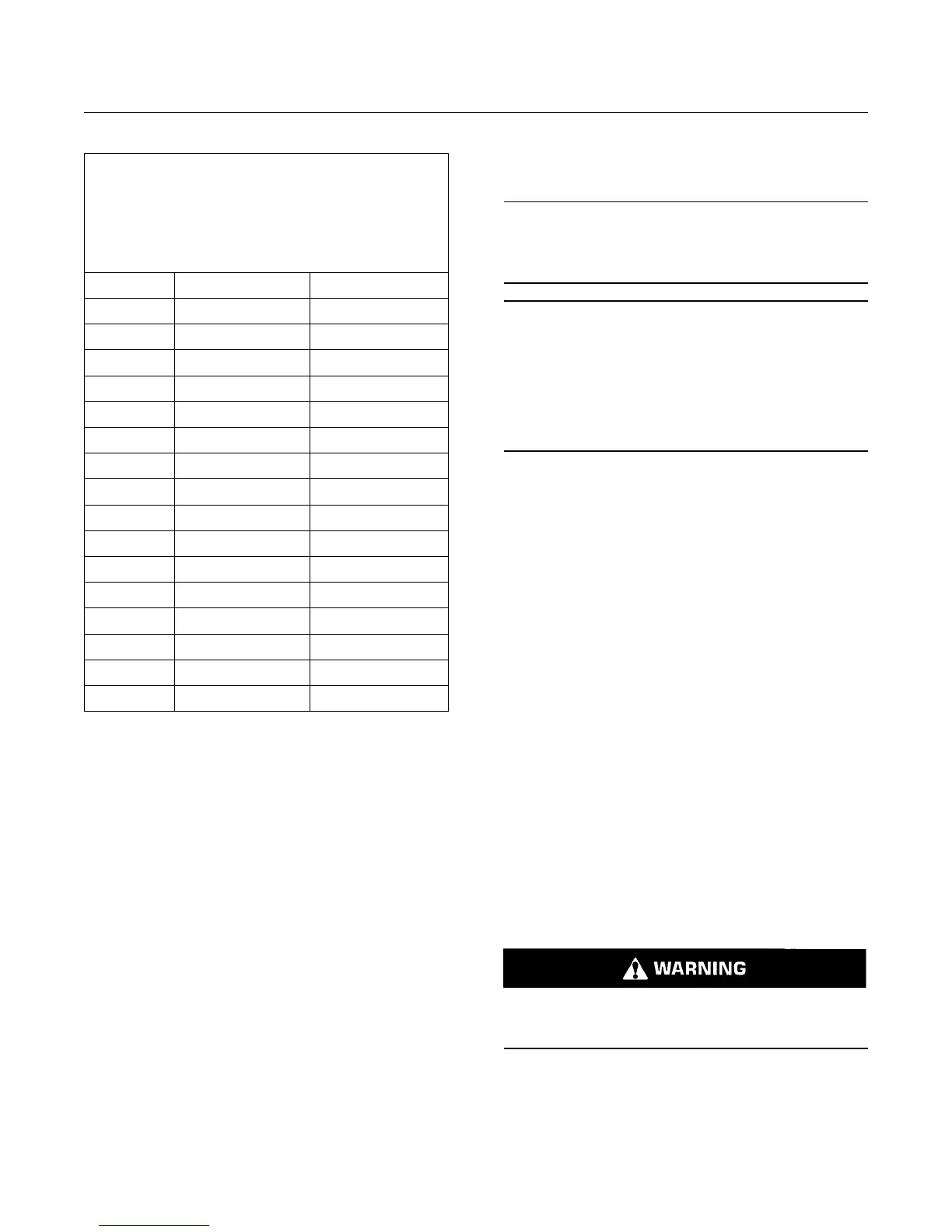

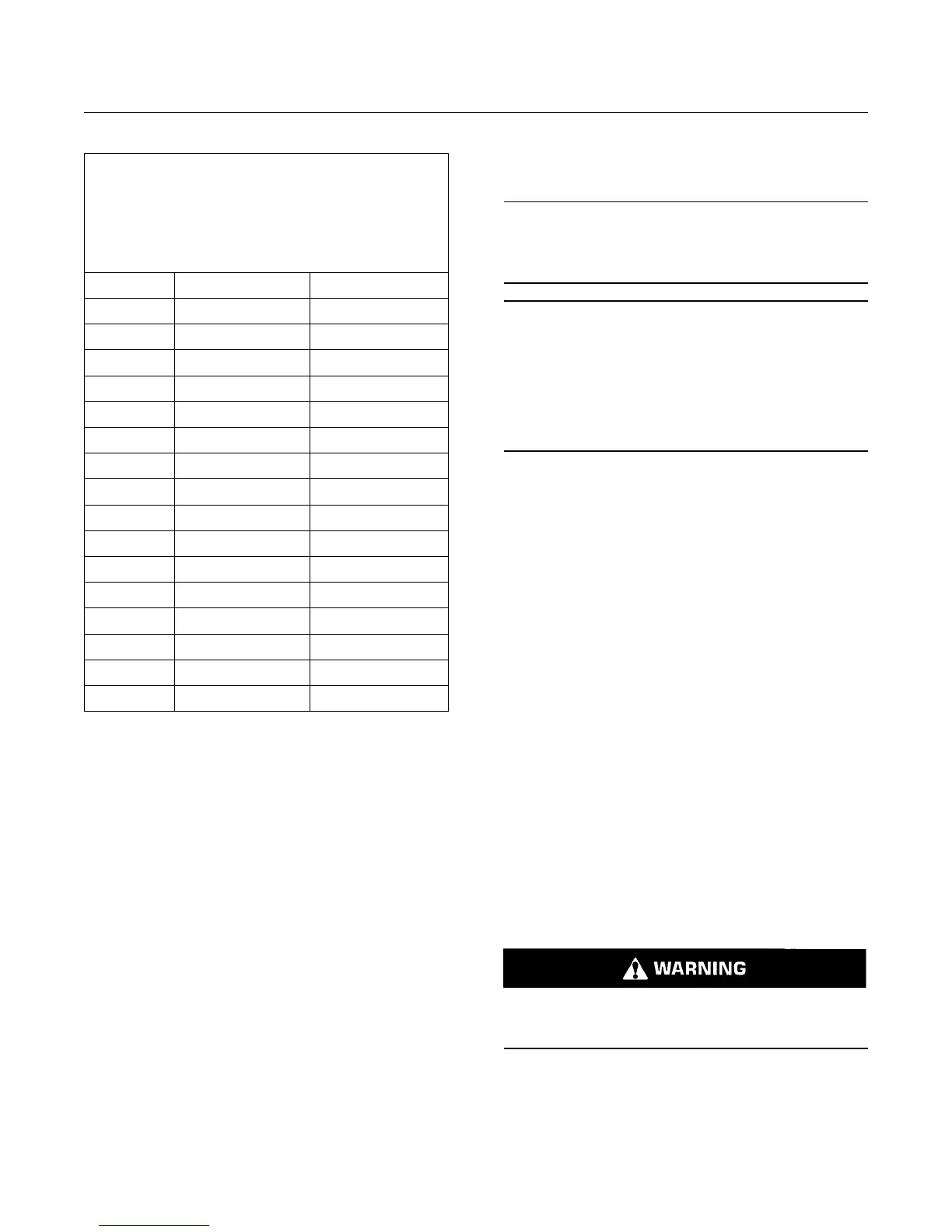

Ta bl e 3 7

Engine Oil Level Gauge

4KG05783-UP

1SK01725-UP

8NM01466-UP

6SR1-UP

1ZJ1-UP

6MK1-UP

Angle

(1)

“FULL” Mark (X) “ADD” Mark (Y)

10 degrees 125 mm (4.92 inch) 114 mm (4.49 inch)

9 degrees 124 mm (4.89 inch) 106 mm (4.17 inch)

8 degrees 122 mm (4.80 inch) 102 mm (4.02 inch)

7 degrees 120 mm (4.72 inch) 96 mm (3.78 inch)

6 degrees 115 mm (4.53 inch) 89 mm (3.50 inch)

5 degrees 110 mm (4.33 inch) 81 mm (3.19 inch)

4 degrees 101 mm (3.98 inch) 71 mm (2.80 inch)

3 degrees 94 mm (3.70 inch) 66 mm (2.60 inch)

2 degrees 90 mm (3.54 inch) 59 mm (2.32 inch)

1 degree 82 mm (3.23 inch) 52 mm (2.05 inch)

0 degrees 76 mm (2.99 inch) 46 mm (1.81 inch)

-1 degree 65 mm (2.56 inch) 39 mm (1.54 inch)

-2 degrees 59 mm (2.32 inch) 33 mm (1.30 inch)

-3 degrees 53 mm (2.09 inch) 26 mm (1.02 inch)

-4 degrees 46 mm (1.81 inch) 20 mm (0.79 inch)

-5 degrees 39 mm (1.54 inch) 12 mm (0.47 inch)

(1)

The angle indicates the number of degrees that the front of

the engine is raised. A negative angle indicates the number of

degrees that the front of the engine is lowered.

Verifying the Calibration of the Oil

Level Gauge

Caterpillar recommends verifying the calibration of

the oil level gauge at the first oil change. Use the

following procedure to verify the “FULL” mark on

the oil level gauge:

Note: The vessel must be level in order to perform

this procedure.

1. Operate the engine until normal operating

temperature is achieved. Stop the engine.

Remove one of the drain plugs for the engine

crankcase. Allow the engine oil to drain.

2. Remove the used engine oil filter. Install the new

engine oil filter. Install the crankcase drain plug

and tighten the crankcase drain plug.

3. Add 25 L (26.5 qt) of the recommended oil grade

and weight of engine oil to the crankcase.

Note: The engine may be equipped with auxiliary

engine oil filters which require additional oil. Refer

to the OEM specifications.

NOTICE

To help prevent crankshaft or bearing damage, crank

engine to fill all filters before starting. Do not crank

engine for more than 30 seconds.

NOTICE

Do not crank the engine for more than 30 seconds.

Allow the starting motor to cool for two minutes before

cranking again.

Turbocharger (if equipped) damage can result, if the

engine rpm is not kept low until the engine oil light/

gauge verifies the oil pressure is sufficient.

4. Start the engine. Ensure that the lubrication

system and the new engine oil filter is filled.

Inspect the lubrication system for leaks.

5. Stop the engine and allow the engine oil to drain

into the engine crankcase for approximately ten

minutes.

6. Check the engine oil level. If necessary, use a

marking pen in order to correct the “FULL” mark

(X).

i01070756

Engine Oil Sample - Obtain

SMCS Code: 1000-008; 1348-554-SM;

7542-554-OC, SM

In addition to a good preventive maintenance

program, Caterpillar recommends using S·O·S oil

analysis at regularly scheduled intervals in order

to monitor the condition of the engine and the

maintenance requirements of the engine.

Obtain the Sample and the Analysis

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

Before you take the oil sample, complete the Label,

PEEP5031 for identification of the sample. In order

to help obtain the most accurate analysis, provide

the following information:

•

Engine model

Loading...

Loading...