84

Maintenance Section

Governor Oil Supply Screen - Clean/Replace

This will help prevent water or sediment from being

pumped from the storage tank into the engine fuel

tank.

If a bulk storage tank has been refilled or moved

recently, allow adequate time for the sediment to

settle before filling the engine fuel tank. Internal

baffles in the bulk storage tank will also help trap

sediment. Filtering fuel that is pumped from the

storage tank helps to ensure the quality of the fuel.

When possible, water separators should be used.

i01015388

Governor Oil Supply Screen -

Clean/Replace

SMCS Code: 1264-070; 1264-510

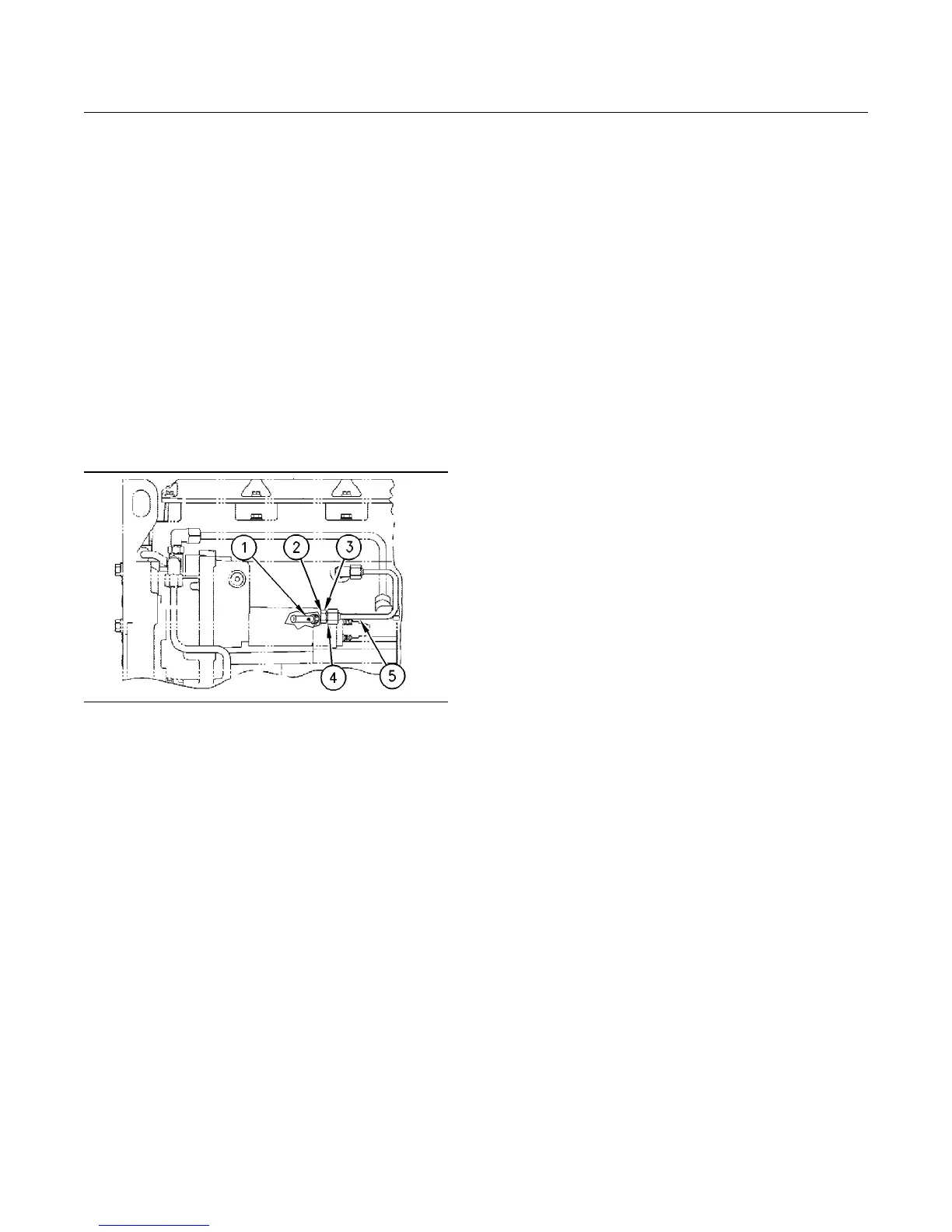

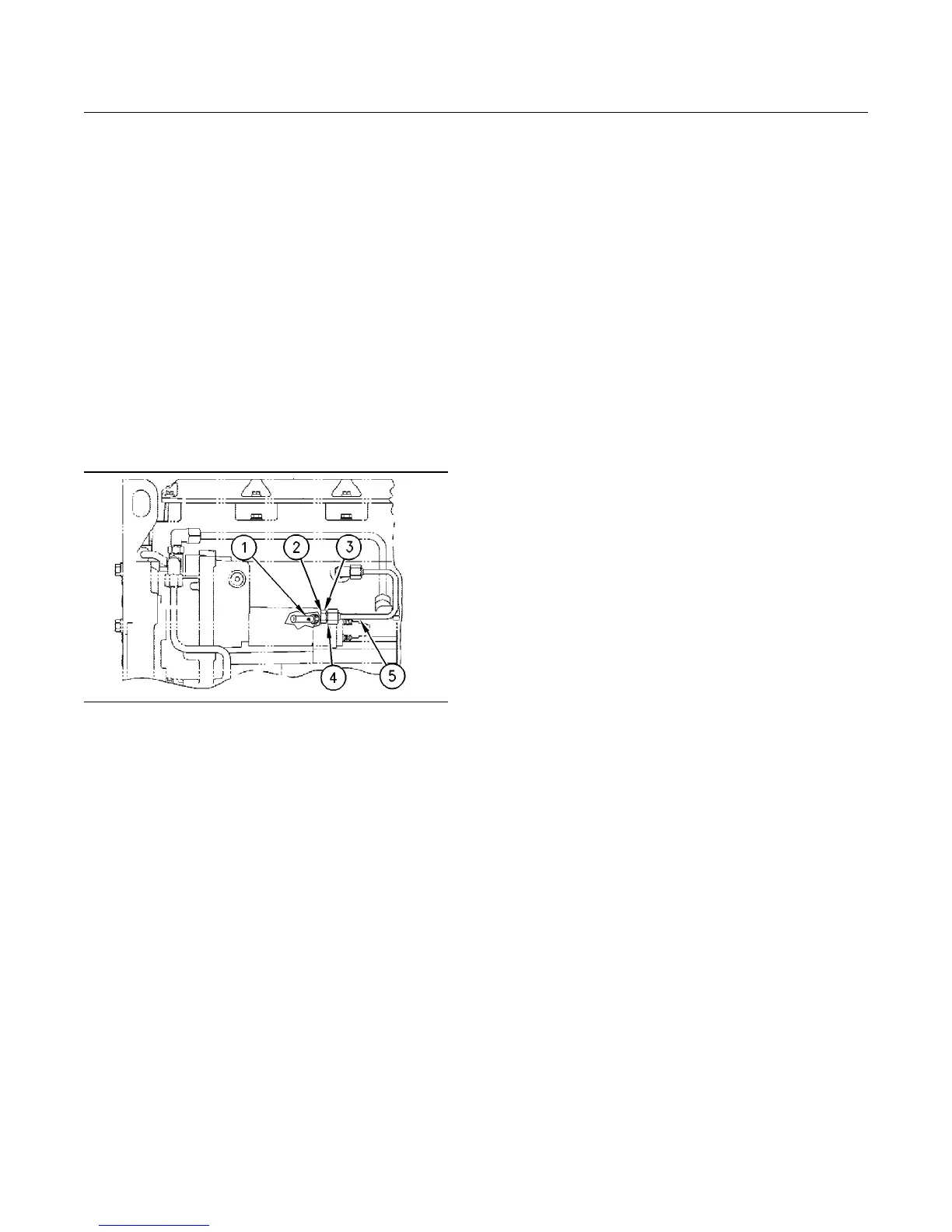

g00521118

Illustration 34

(1) Screen

(2) Seal

(3) Fitting

(4) Seals

(5) Oil supply tube

1. Remove oil supply tube (5) and seals (4) from

the cylinder head.

2. Remove fitting (3) and seal (2) from the governor

housing.

3. Remove screen (1).

4. Wash screen (1) in solvent in order to remove

any debris. Inspect screen (1) for damage and

inspect screen (1) for deterioration. If necessary,

obtain a new screen. Inspect all seals for

damage and deterioration. If necessary, obtain

new seals.

5. Install screen (1) into the governor housing. The

screen must be far enough into the governor

housing in order to allow clearance for seals (2)

and fitting (3).

6. Install seals (2), fitting (3), seal (4) and oil supply

tube (5).

i01057362

Heat Exchanger - Inspect

SMCS Code: 1379-040

The interval for the maintenance of the tube and

fin heat exchanger depends on the operating

environment of the vessel and on the operating

time. The sea water that is circulated through the

heat exchanger and the amount of operating time

of the vessel affects the following items:

•

Cleanliness of the tubes of the heat exchanger

•

Effectiveness of the heat exchanger system

Operating in water that contains silt, sediment, salt,

algae, etc will adversely affect the heat exchanger

system. In addition, intermittent use of the vessel

will adversely affect the heat exchanger system.

The following items indicate that the heat exchanger

may require cleaning:

•

Increased coolant temperature

•

Engine overheating

•

Excessive pressure drop between the water inlet

and the water outlet

An operator that is familiar with the normal operating

temperature of the coolant can determine when

the coolant temperature is out of the normal range.

Inspection and maintenance of the heat exchanger

are required if the engine is overheating.

Your Caterpillar dealer has the equipment and

the trained personnel that are needed in order

to measure the pressure drop across the heat

exchanger.

The procedure for cleaning the heat exchanger is

similar to the procedure that is used for cleaning

the aftercooler core. Refer to the Operation and

Maintenance Manual, “Aftercooler Core - Clean/Test”

topic (Maintenance Section). For more information

on servicing the heat exchanger, consult your

Caterpillar dealer.

i00907072

Hoses and Clamps -

Inspect/Replace

SMCS Code: 7554-040; 7554-510

Inspect all hoses for leaks that are caused by the

following conditions:

Loading...

Loading...