Avoid direct spraying of water on electrical

connectors, connections, and components. When

using air for cleaning, allow the machine to cool to

reduce the possibility of fine debris igniting when

redeposited on hot surfaces.

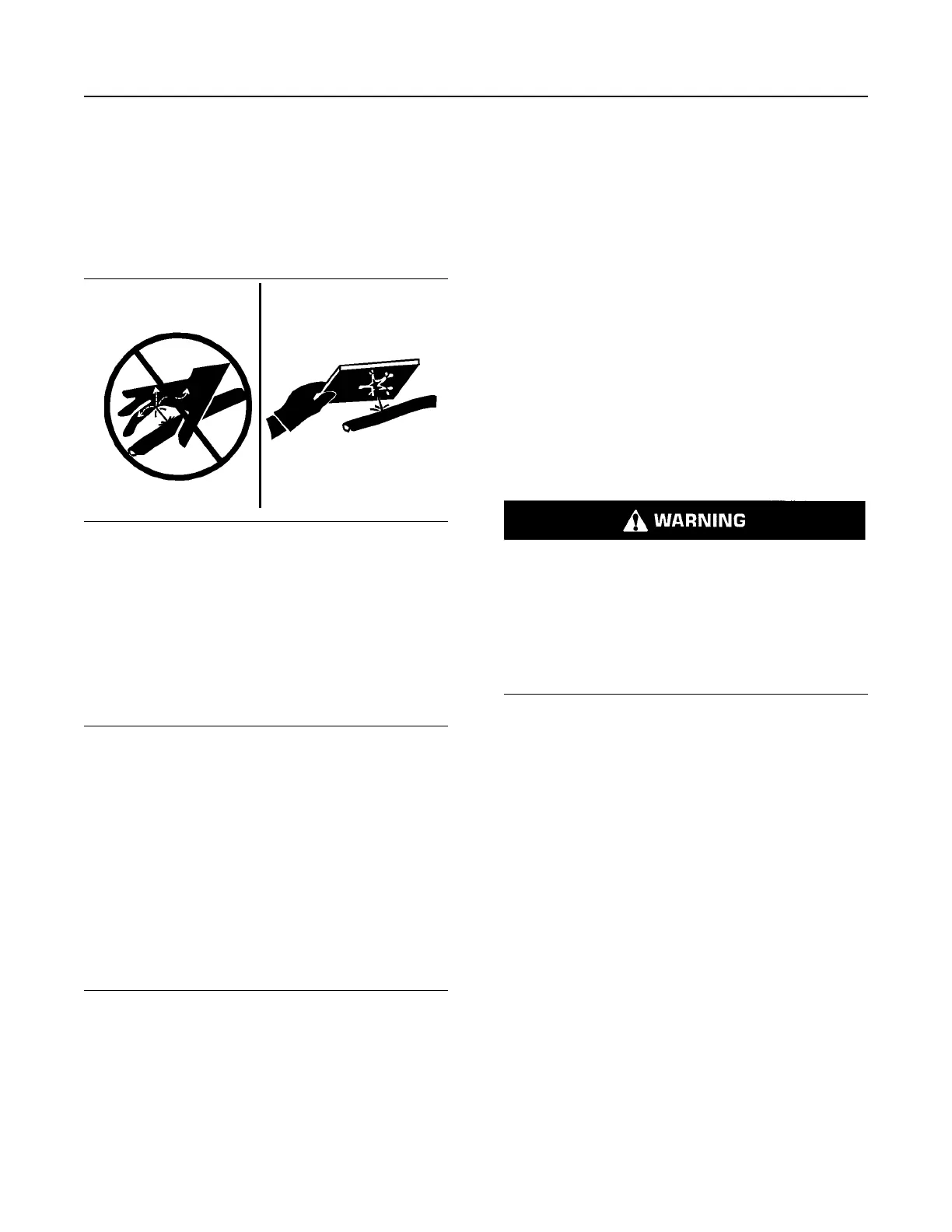

Fluid Penetration

Illustration 17 g00687600

Always use a board or cardboard when you check for

a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

Containing Fluid Spillage

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting, and repair of the product.

Be prepared to collect the fluid with suitable contain-

ers before opening any compartment or disassem-

bling any component containing fluids.

Refer to Special Publication, NENG2500, “Cat Dealer

Service Tool Catalog” or refer to Special Publication,

PECJ0003, “Cat Shop Supplies and Tools Catalog”

for tools and supplies suitable to collect and contain

fluids on Cat products.

Dispose of all fluids according to local regulations

and mandates.

Static Electricity Hazard when

Fueling with Ultra-low Sulfur Diesel

Fuel

The removal of sulfur and other compounds in ultra-

low sulfur diesel fuel (ULSD fuel) decreases the

conductivity of ULSD and increases the ability of

ULSD to store static charge. Refineries may have

treated the fuel with a static dissipating additive.

Many factors can reduce the effectiveness of the

additive over time. Static charges can build up in

ULSD fuel while the fuel is flowing through fuel

delivery systems. Static electricity discharge when

combustible vapors are present could result in a fire

or explosion. Ensure that the entire system used to

refuel your machine (fuel supply tank, transfer pump,

transfer hose, nozzle, and others) is properly

grounded and bonded. Consult with your fuel or fuel

system supplier to ensure that the delivery system

complies with fueling standards for proper grounding

and bonding.

Avoid static electricity risk when fueling. Ultra-

low sulfur diesel fuel (ULSD fuel) poses a greater

static ignition hazard than earlier diesel formula-

tions with a higher sulfur contents. Avoid death

or serious injury from fire or explosion. Consult

with your fuel or fuel system supplier to ensure

the delivery system is in compliance with fueling

standards for proper grounding and bonding

practices.

Lines, Tubes, and Hoses

Do not bend or strike high-pressure lines. Do not

install lines, tubes, or hoses that are damaged.

Repair any fuel lines, oil lines, tubes, or hoses that

are loose or damaged. Leaks can cause fires.

Inspect all lines, tubes, and hoses carefully. Do not

use bare hands to check for leaks. Always use a

board or cardboard for checking engine components

for leaks. Tighten all connections to the

recommended torque.

Check for the following conditions:

• End fittings that are damaged or leaking

• Outer covering that is chafed or cut

• Wire that is exposed in reinforced hose

• Outer covering that is ballooning locally

• Flexible part of the hose that is kinked or crushed

• Armoring that is embedded in the outer covering

10

SEBU7125-13

Safety Section

General Hazard Information

Loading...

Loading...