2. Wait for ten minutes.

Do not loosen the high pressure fuel lines in order to

remove air pressure from the fuel system.

Engine Oil

To relieve pressure from the lubricating system, turn

off the engine.

i05909227

Welding on Engines with

Electronic Controls

SMCS Code: 1000

NOTICE

Because the strength of the frame may decrease,

some manufacturers do not recommend welding onto

a chassis frame or rail. Consult the OEM of the equip-

ment or your Cat dealer regarding welding on a chas-

sis frame or rail.

Proper welding procedures are necessary in order to

avoid damage to the engine ECM, sensors, and

associated components. When possible, remove the

component from the unit and then weld the

component. If removal of the component is not

possible, the correct procedure must be followed.

When welding on a unit that is equipped with a Cat

Electronic Engine, the following is considered to be

the safest procedure:

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding

can cause damage to the drive train, the bearings,

hydraulic components, electrical components, and

other components.

Do not ground the welder across the centerline of the

package. Improper grounding could cause damage

to the bearings, the crankshaft, the rotor shaft, and

other components.

Clamp the ground cable from the welder to the com-

ponent that will be welded. Place the clamp as close

as possible to the weld. This will help reduce the pos-

sibility of damage.

Note: Perform the welding in areas that are free from

explosive hazards.

1. Stop the engine. Turn the switched power to the

OFF position.

2. Disconnect the negative battery cable from the

battery. If a battery disconnect switch is provided,

open the switch.

3. Disconnect the J1/P1 and J2/P2 connectors from

the ECM. Move the harness to a position that will

not allow the harness to move back accidentally,

and contact any of the ECM pins.

4. Disconnect any component with a microprocessor

from the engine harness, such as:

• Engine ECM

• Product Link

• Cell/Sat Radio

• DOC Identity Modules

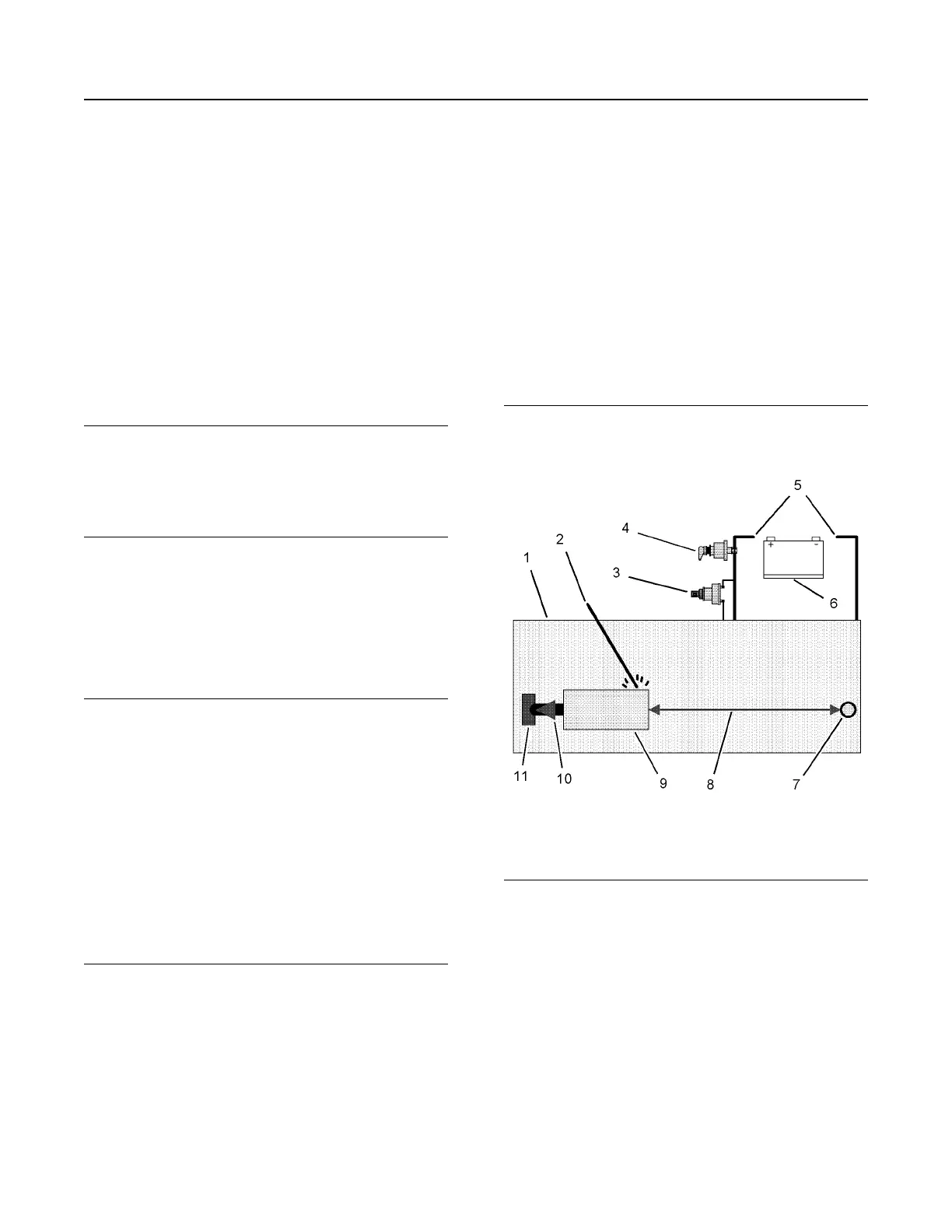

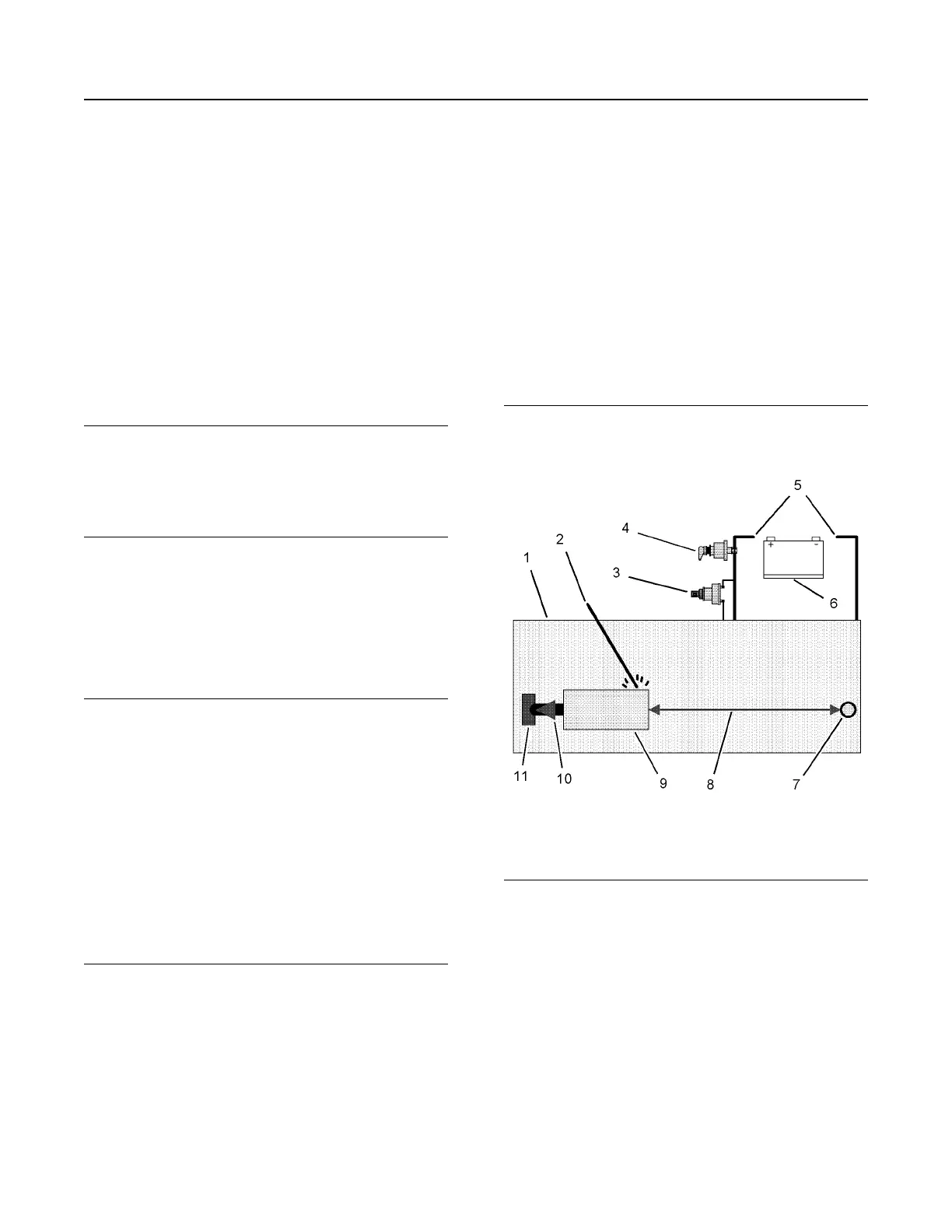

Illustration 94 g01075639

Use the example above. The current flow from the

welder to the ground clamp of the welder will not

damage any associated components.

(1) Engine

(2) Welding electrode

(3) Keyswitch in the OFF position

(4) Battery disconnect switch in the open position

(5) Disconnected battery cables

(6) Battery

(7) Electrical/Electronic component

(8) Minimum distance between the component that is being

welded and any electrical/electronic component

(9) The component that is being welded

(10) Current path of the welder

(11) Ground clamp for the welder

100

SEBU7125-13

Maintenance Section

Welding on Engines with Electronic Controls

Loading...

Loading...