5. Connect the welding ground cable directly to the

part that will be welded. Place the ground cable as

close as possible to the weld. This location will

reduce the possibility of welding current damage

to bearings, hydraulic components, electrical

components, and ground straps.

Note: If electrical/electronic components are used as

a ground for the welder, current flow from the welder

could severely damage the component. Current flow

from the welder could also severely damage

electrical/electronic components that are located

between the welder ground and the weld.

6. Protect the wiring harness from welding debris and

spatter.

7. Use standard welding practices to weld the

materials.

i01227545

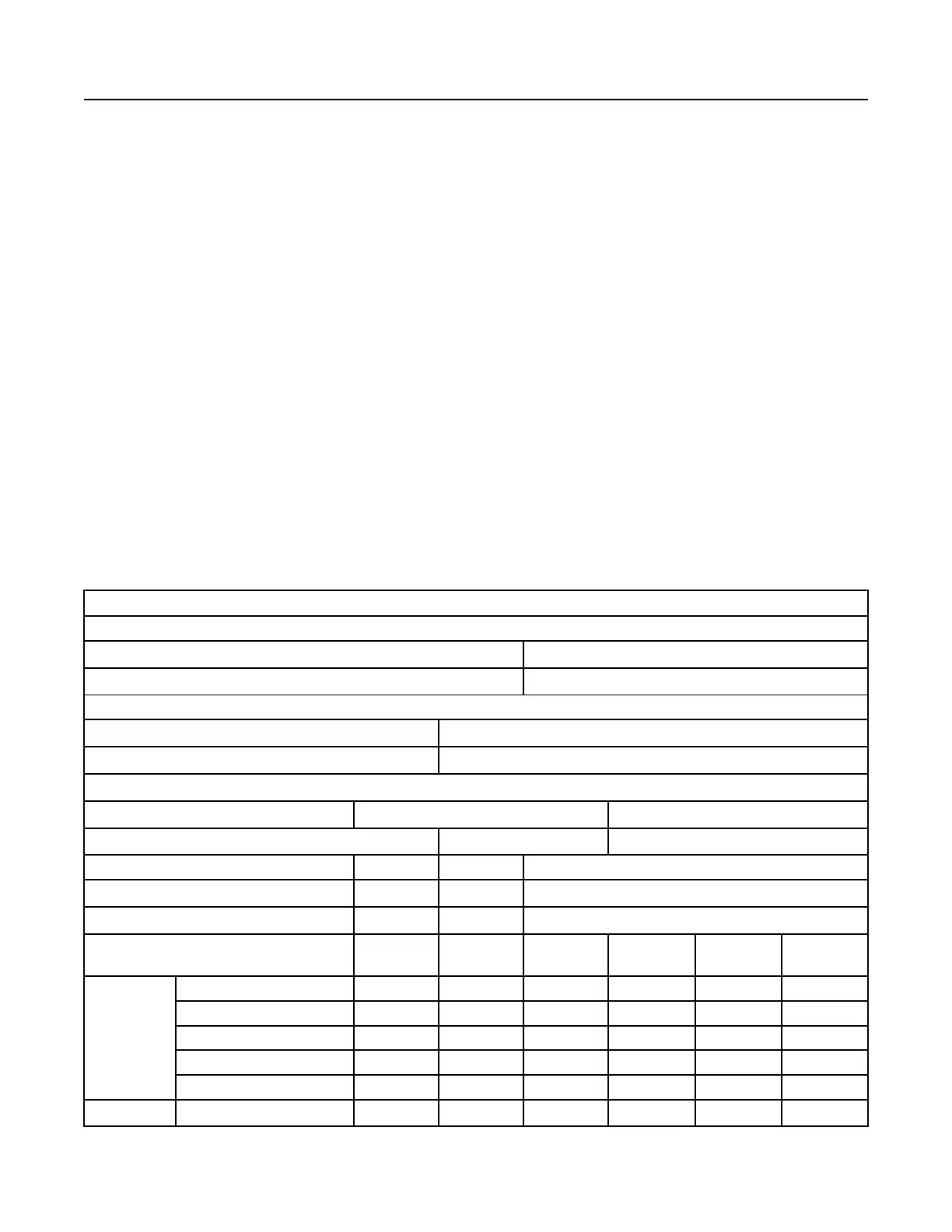

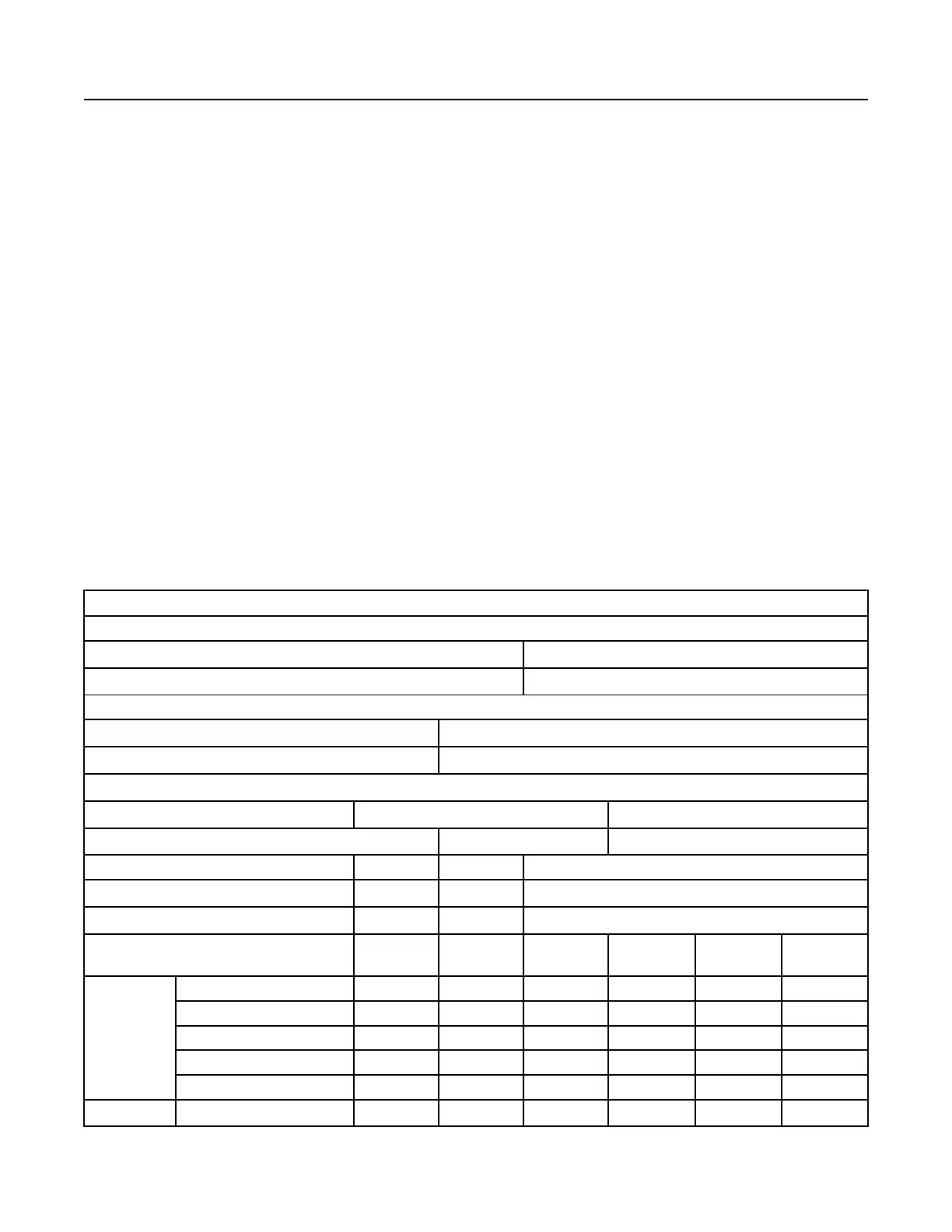

Generator Start-up Checklist

SMCS Code: 4450

Table 16

GENERATOR START-UP CHECKLIST

RATING INFORMATION

Engine Serial Number: ___________________________________ Arrangement Number: ___________________

Generator Serial Number: _________________________________ Arrangement Number: ___________________

GENERATOR NAME PLATE INFORMATION

Voltage: ___________________ Package (prime, continuous, standby): _________________

Amperage: _________________ Kilowatts: ________________________________________

Storage Location:

Main Stator Megohmmeter Reading: Before Storage: After Storage:

Generator dried for 24 hours prior to startup? (Y/N) Drying method:

SPACE HEATERS Yes No Comments

Space heaters operating properly?

Space heater operated 48 hrs. before startup?

MEGOHMMETER TEST (SEHS9124) 30 sec.

reading

60 sec.

reading

30 sec.

corrected

60 sec.

corrected

Ambient temp. Comments

Beginning of

Storage

Main Stator

Main Rotor

Exciter Stator

Exciter Rotor

PMG Stator

Start-up Main Stator

(continued)

SEBU7125-13

101

Maintenance Section

Generator Start-up Checklist

Loading...

Loading...