3. Verify that the following items are not functioning:

electrical components, hour meter and engine

cranking. If any of the items continue to function

with the battery disconnect switch in the OFF

position, consult your Caterpillar dealer.

i01927889

Engine Shutoffs and Engine

Alarms

SMCS Code: 1900; 7400; 7418

Shutoff and Alarm Systems

Shutoffs and alarms are electrically operated or

mechanically operated. The operation of all electric

shutoffs and alarms utilize components which

actuate switches in a sensing unit.

Shutoffs are set at more critical levels for the

operating temperature, operating pressure, operating

coolant level, and operating speed (rpm) than the

alarms. The particular shutoff may need to be reset

before the engine will start.

NOTICE

Always determine the cause of the engine shutdown.

Make necessary repairs before attempting to restart

the engine.

Be familiar with the following items:

• Types and locations of shutoff

• Conditions which cause each shutoff to function

• The resetting procedure that is required to restart

the engine

Alarm switches consist of a sensor and a contactor.

Examples of sensors are the magnetic pickup for

detecting speed, and the pressure and temperature

sensors. Sensors are wired to contactors. The

contactors activate alarm circuits in the annunciator

panel.

Alarm switches are set at less critical levels than the

shutoffs. The alarms warn the operator that an

unsafe operating condition is occurring. The engine

will continue to run when an alarm sounds.

When an alarm is activated, corrective measures

must be taken before the situation becomes an

emergency in order to avoid possible engine

damage. If corrective measures are not taken within

a reasonable time, engine damage could result.

Alternatively, a corresponding shutdown device (if

equipped) will stop the engine. The alarm will

continue until the condition is corrected or the alarm

is reset by the operator.

A switch may be installed in the alarm circuit for

silencing the alarm while the engine is stopped for

repairs. Before starting, be sure that the switch is

moved to the closed ON. Be sure that the warning

lamps will operate. The engine will not be protected if

the switch is left in the open OFF position.

NOTICE

Always determine the cause of the engine shutdown.

Make necessary repairs before attempting to restart

the engine.

Air Shutoff Solenoid (If Equipped)

This optional solenoid is located on top of the engine.

The air shutoff is part of the air inlet system. When

the solenoid is activated, the solenoid mechanically

shuts off the inlet air to the engine. The solenoid can

be activated only by the overspeed switch or by the

emergency stop push button (ESPB). The air shutoff

must be reset before the engine is restarted.

Fuel Shutoff Solenoid

The fuel shutoff solenoid is located on the governor

or the fuel shutoff solenoid is located on the fuel

injection pump. When the fuel shutoff solenoid is

activated, the solenoid moves the fuel rack “OFF” .

The fuel shutoff solenoid moves the fuel rack directly

or the fuel shutoff solenoid moves the fuel rack

through the governor.

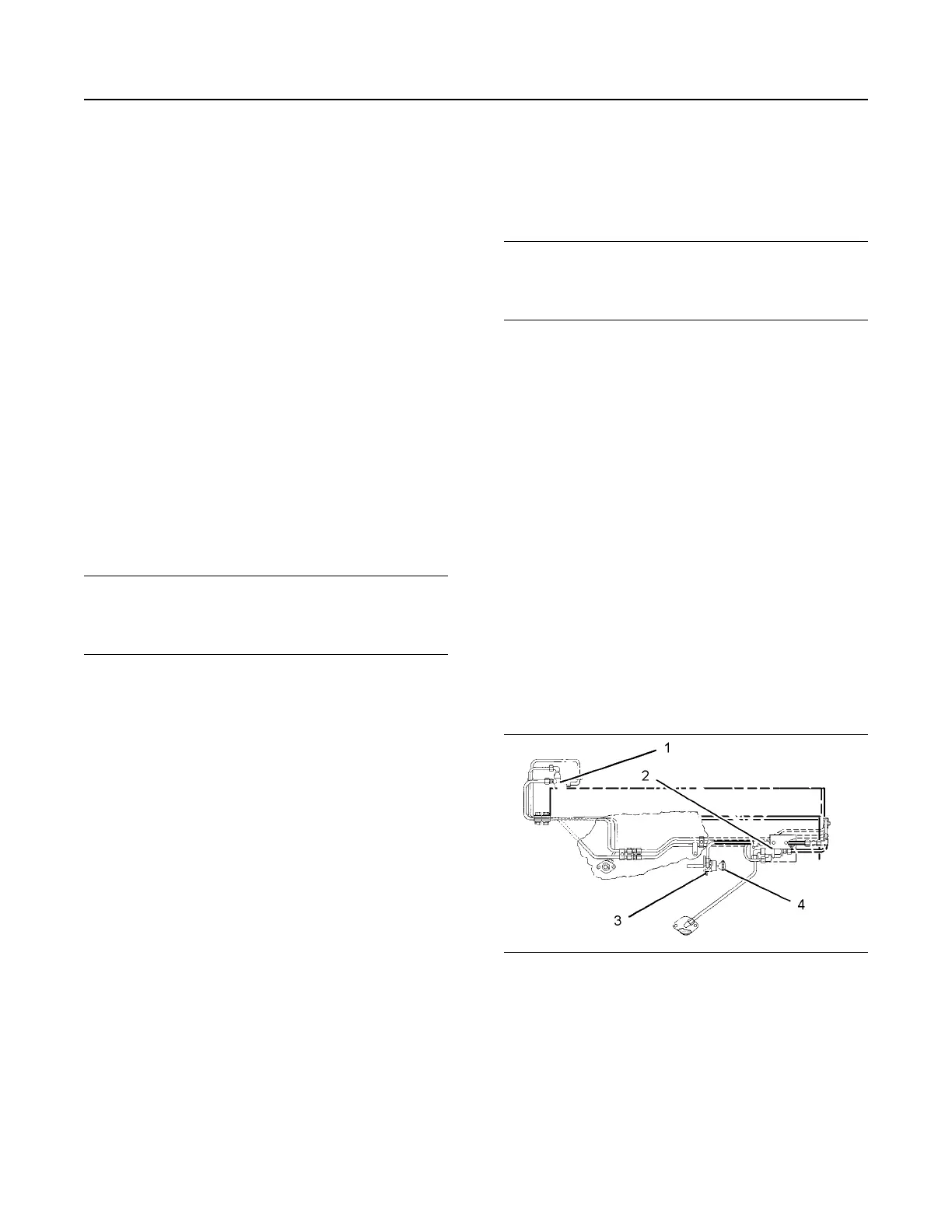

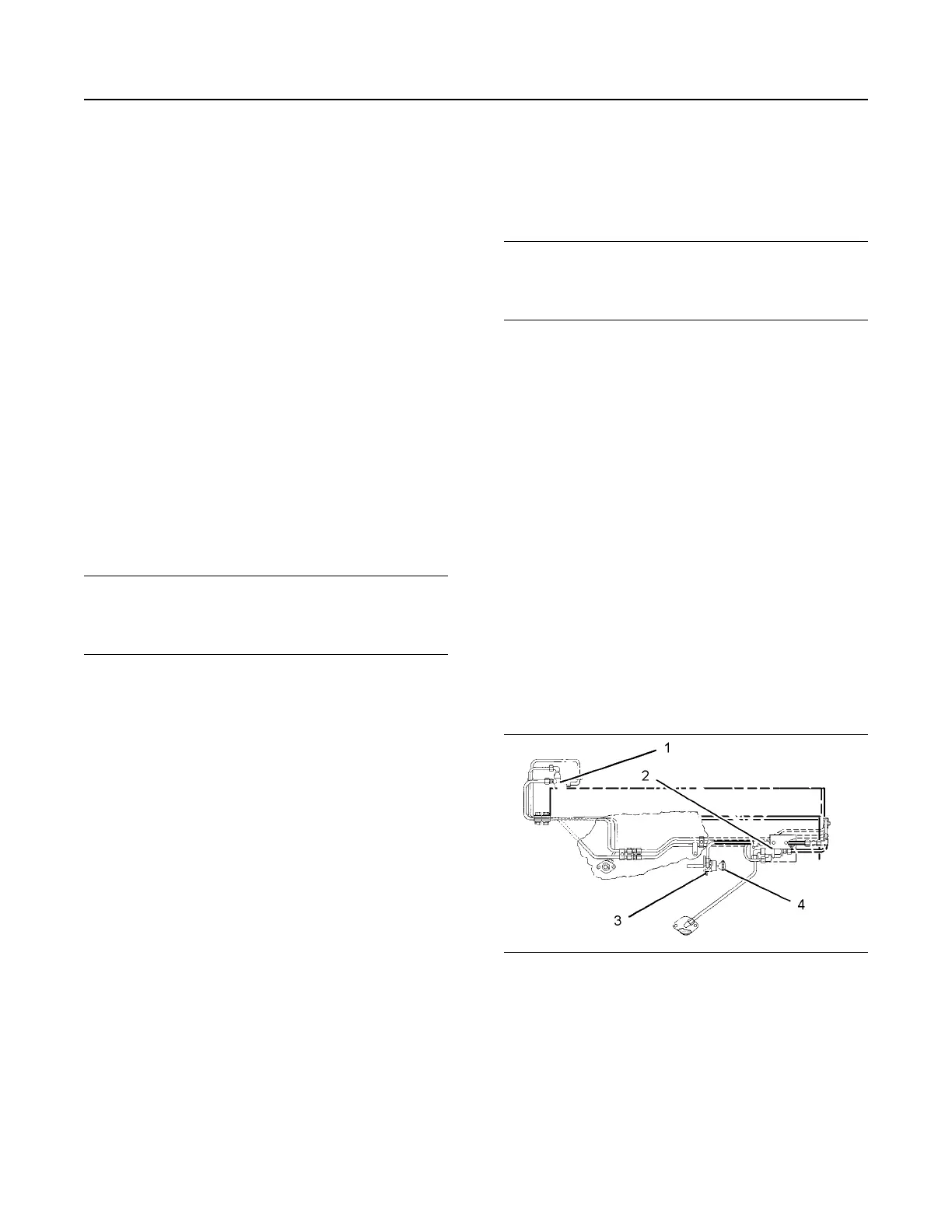

Mechanical Oil Pressure and Water

Temperature Shutoff

Illustration 77 g01009004

(1) Water temperature sensing valve

(2) Oil pressure sensing valve

(3) Shutdown cylinder

(4) Shutdown cylinder knob

70

SEBU7125-13

Operation Section

Engine Shutoffs and Engine Alarms

Loading...

Loading...