A mechanical shutoff system (if equipped) provides

protection for low oil pressure and for high water

temperature. The main components are a water

temperature sensing valve (1), a oil pressure sensing

valve (2), and a shutdown cylinder (3). Pull out the

shutdown cylinder knob (4) while you start the

engine. Hold the knob out until the engine develops

enough oil pressure. When the engine has

developed enough pressure, the knob will stay in

place. If low oil pressure or if high water temperature

is sensed, the knob will be released and the plunger

in the governor housing will hold the fuel rack in the

“FUEL OFF” position.

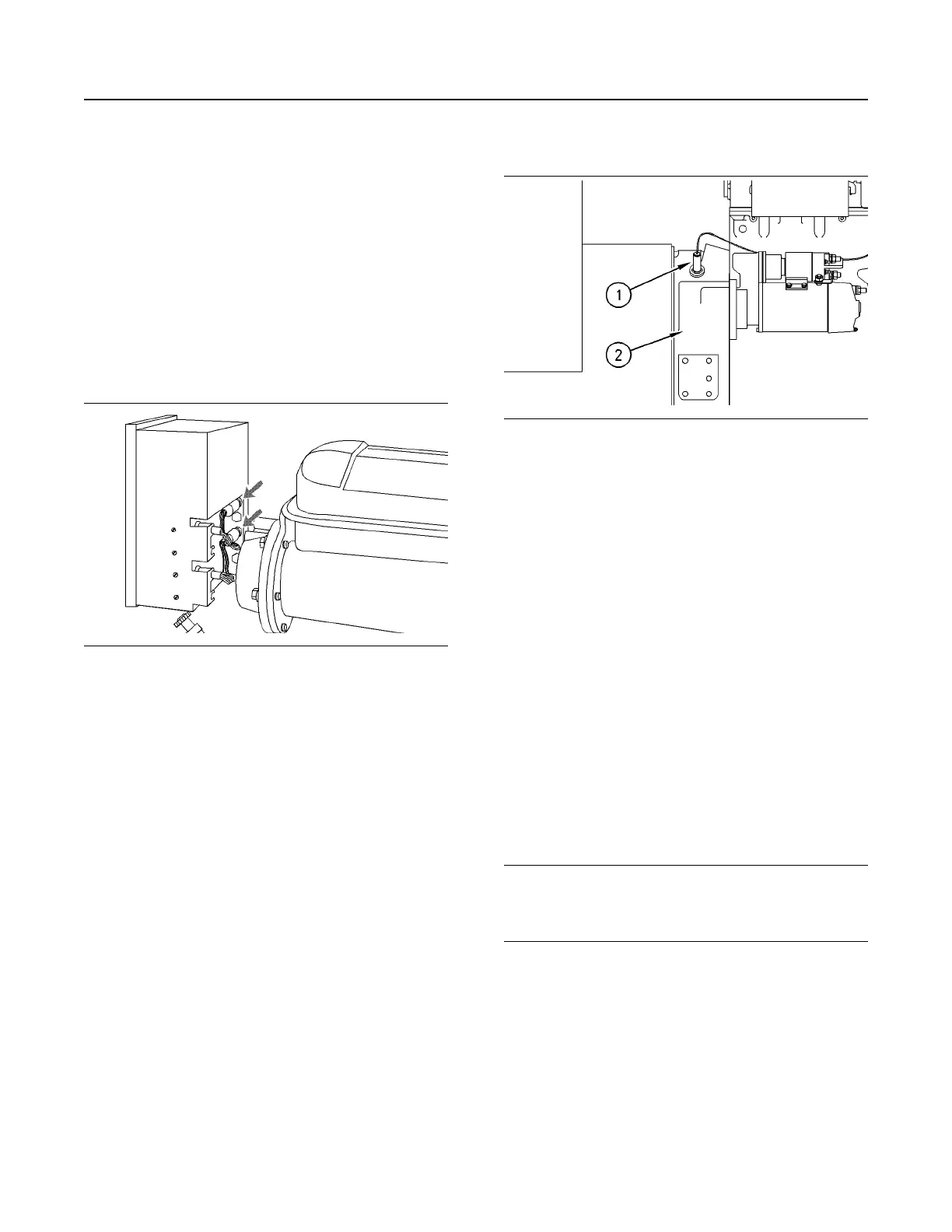

Oil Pressure Switches

Illustration 78 g01008923

Typical example

An oil pressure switch has wires that are connected

to the electrical system for the alarm and/or for the

shutoff. The oil pressure switch senses oil pressure

at the bearing oil gallery. If sufficient oil pressure is

not achieved after engine starting, or if the engine is

running and then loses oil pressure, the fuel shutoff

solenoid is energized to shut the engine off. No

resetting procedure is required.

Engine Step Oil Pressure

This is an adjustable engine speed setting that

protects the engine from a failure that is caused by

too little oil pressure for a specified speed range. This

option requires two different oil pressure switches.

One switch has a high pressure rating. When the

engine is running above the speed setting, the

engine must maintain oil pressure higher than the

rating of the switch. The other switch has a low

pressure rating. When the engine is running below

the speed setting, the engine must maintain oil

pressure above the rating of the switch. In an

automatic start/stop system, an automatic reset

switch is used.

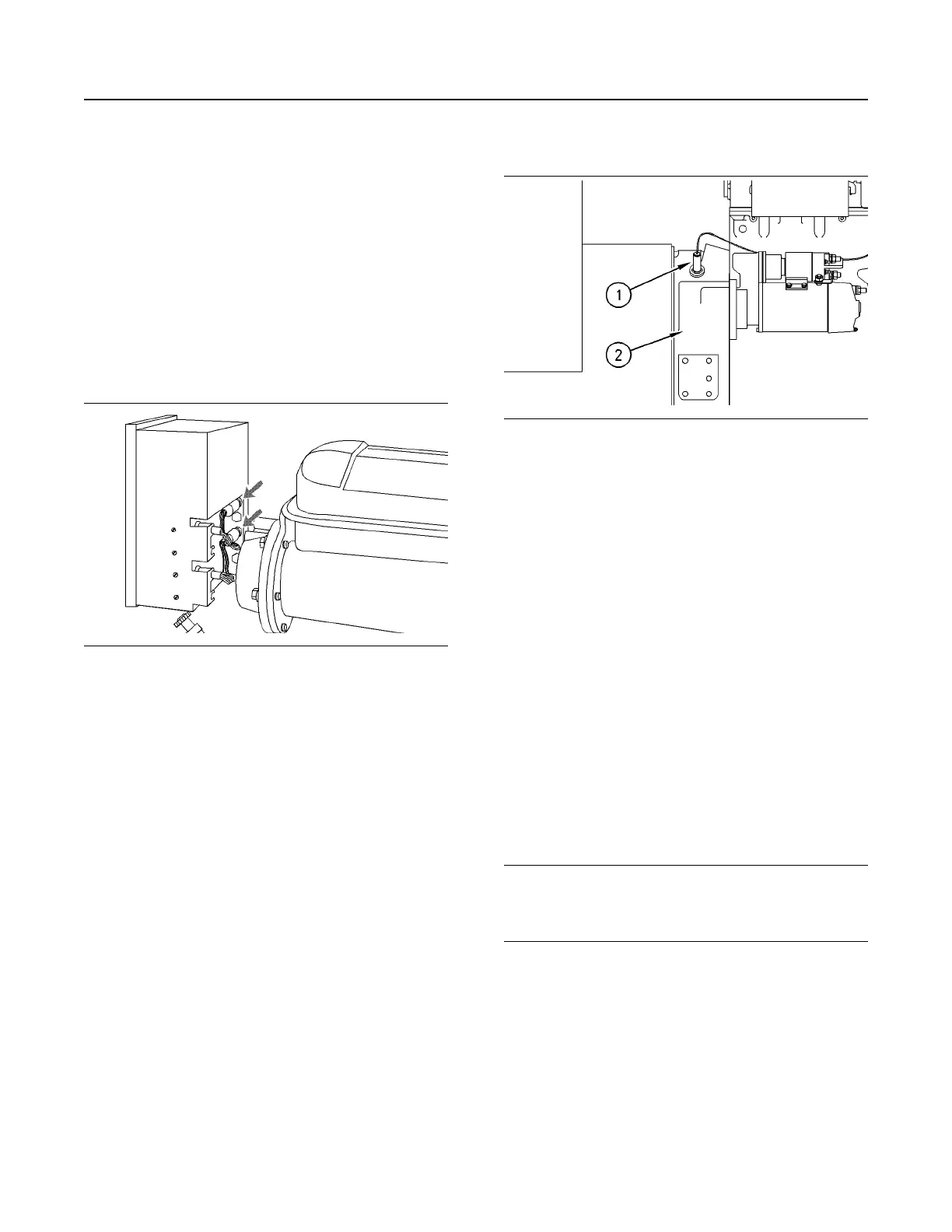

Overspeed Shutoffs

Illustration 79 g00293335

(1) Magnetic pickup

(2) Flywheel housing

The magnetic pickup senses the passage of the teeth

that are on the flywheel ring gear. The Electronic

Overspeed Switch is set at 118 percent of the rated

engine speed. If the engine speed increases above

the overspeed setting, the magnetic pickup will sense

the overspeed. A signal is sent to the Electronic

Overspeed Switch. The Electronic Overspeed Switch

activates both the air shutoff solenoid (if equipped)

and the fuel shutoff solenoid.

The shutoffs must be reset before the engine will

restart. The air shutoff lever that is located at the top

of the air inlet housing must be manually reset. The

cause of the overspeed must be determined before

the engine is restarted.

Water Temperature Contactor Switch

The water temperature contactor switch is located in

the cylinder head. High water temperature closes the

switch which activates an alarm or fuel shutoff. No

resetting is required. The switch will open as the

coolant cools.

NOTICE

Coolant level must be maintained in order for the

shutoff to function, because the sensing element

must be submerged in the coolant to operate.

Coolant Loss Sensor (If Equipped)

The optional coolant loss sensor is usually mounted

near the top of the expansion tank or radiator. The

sensor monitors the coolant level.

SEBU7125-13

71

Operation Section

Engine Shutoffs and Engine Alarms

Loading...

Loading...