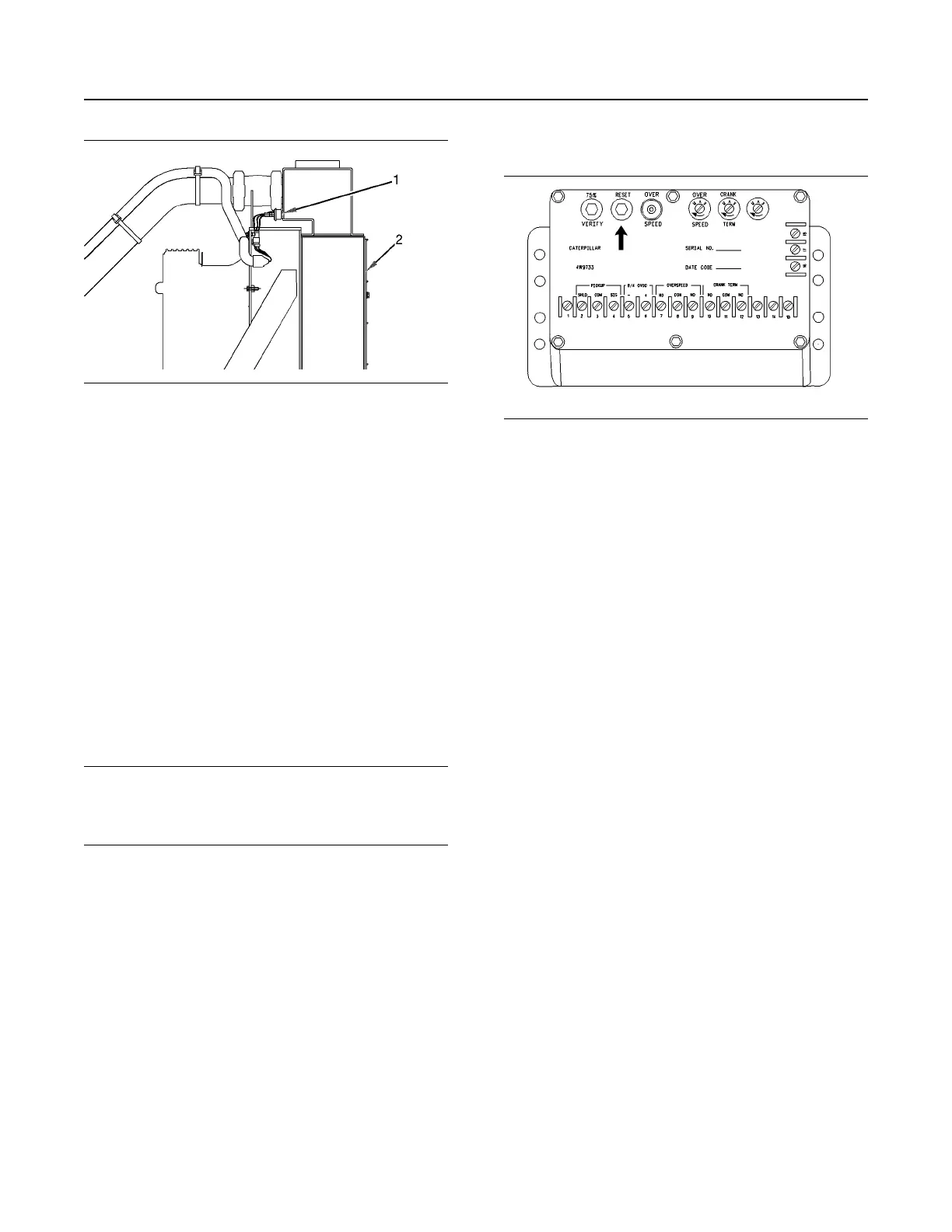

Illustration 80 g01009211

(1) Typical coolant loss sensor

(2) Radiator

If the coolant drops below the minimum level, the

sensor may sound an alarm, or the sensor may

cause a shutoff to avoid engine overheating or

possible engine damage. Coolant must be added to

the radiator or the expansion tank in order to reset

the condition.

Testing the Shutoff and Alarm

System

Most control panels are equipped with a lamp test

switch. Turn the switch to the ON position in order to

check the indicator lights for proper operation.

Replace worn bulbs immediately.

The shutoffs and alarms should be tested every 1000

service hours or twice a year for proper operation by

authorized, experienced service personnel.

NOTICE

During testing, abnormal operating conditions must

be simulated. Perform the tests correctly in order to

help prevent possible engine damage.

Refer to the Service Manual for more information on

testing procedures or consult your Caterpillar dealer.

Testing of the Overspeed Switch

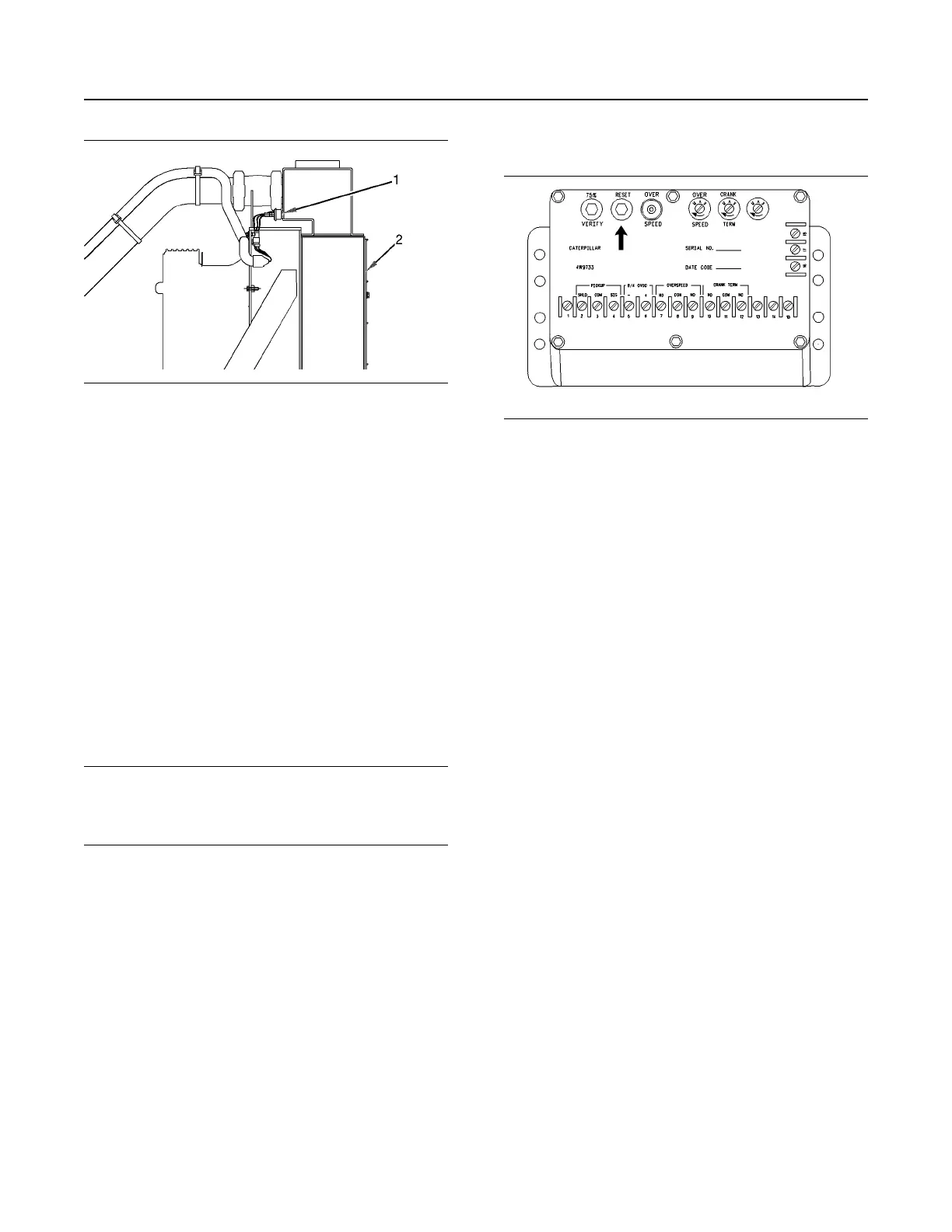

Illustration 81 g00291056

Electronic Overspeed Switch

The overspeed shutoff switch is located in the

junction box. The overspeed shutoff switch must be

reset before you can restart the engine. To reset the

switch, push the “RESET” button. The button will

remain in this position unless an overspeed condition

occurs.

The Electronic Overspeed Switch with Cranking

Termination has a 75 percent “VERIFY” button, a

“RESET” button, and an “OVERSPEED” indicator

lamp.

The Electronic Overspeed Shutoff Switch with

Cranking Termination has a sensing circuit which

prevents the starter pinion from remaining engaged

in the flywheel at excessive rpm. Crank Termination

has an adjustable engine speed setting. This signals

the starter motor when the engine is firing and

cranking must be terminated. Once the speed setting

is reached, a switch opens. This will start the engine

hour meter.

Once the starting motor cranks the engine, the pinion

gear can remain engaged with the flywheel as the

engine speed increases. The magnetic pickup opens

the circuit to the starting motor at 400 rpm. This will

allow the pinion gear to disengage.

The circuit will remain open until the flywheel stops.

This prevents energizing the starting motor circuit

again while the flywheel is turning.

The engine may be equipped with either an

Overspeed Shutoff Switch or an Electronic

Overspeed Switch with Cranking Termination. Both

switches can be checked for proper operation at 75

percent of overspeed condition. Use the following

procedure:

1. Determine full load speed (rpm) from the Engine

Information Plate.

2. Operate the engine at the corresponding speed

(rpm) that is shown for the engine. Refer to table 3

.

72

SEBU7125-13

Operation Section

Engine Shutoffs and Engine Alarms

Loading...

Loading...