FORCECLIMA 12600 SOUNDLESS HEATING FORCECLIMA 12600 SOUNDLESS HEATING

7574

ENGLISH ENGLISH

- If compressors and compressor oils are to be removed, ensure that they have been drained

evacuation process must be carried out before returning the compressor to the suppliers.

Only electrical heating of the compressor body should be used to accelerate this process.

When oil is drained from a system, it must be done in a safe manner.

7. TECHNICAL SPECIFICATIONS

Product: ForceClima 12600 SoundLess Heating

Product reference: 08176

Power Supply: 220-240 V~, 50 Hz

Consumption in Standby mode: < 1 W

Maximum suction pressure: 0.6 MPa

Minimum unload pressure: 1.8 MPa

Maximum pressure allowed: 3.0 MPa

Air volume: 400 m3/h

Remote control: 2 x 3AAA batteries

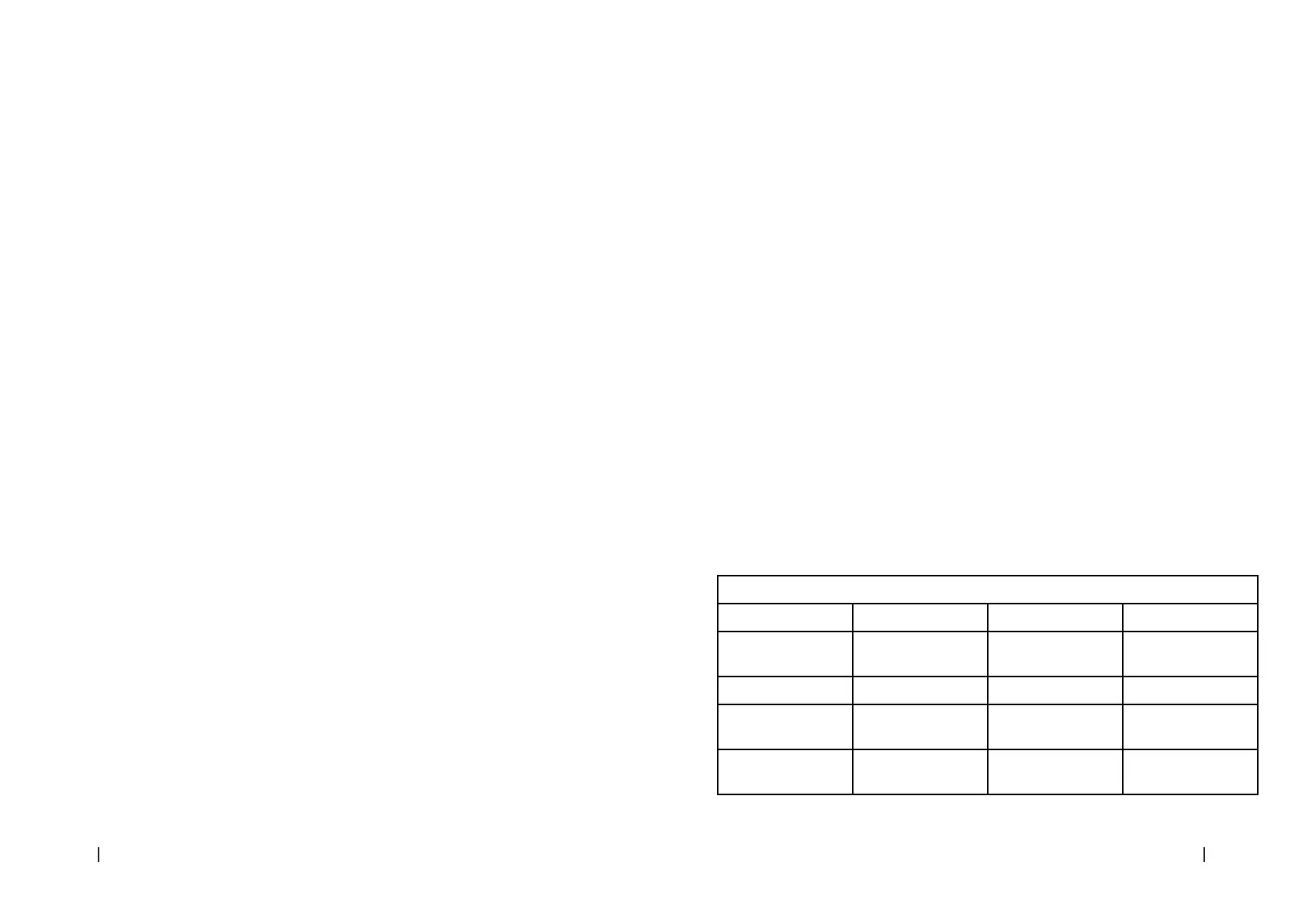

08176 ForceCLima 12600 SoundLess Heating

Description Symbol Value Unit

Rated cooling

capacity

P

rated

for cooling 2.64 KW

Rated heating P

rated

for heating 2.05 KW

Rated power used for

cooling

P

EER

1.01 KW

Rated power used for

heating

P

COP

KW

-

-

-

D. Pump the cooling system, if possible.

E. If vacuum is not possible, make a manifold so that refrigerant can be removed from various

parts of the system.

F. Ensure that the cylinder is positioned on the scale before recovery takes place.

G. Switch on the recovery machine and operate it according to the manufacturer’s instructions.

H.

I. Do not exceed the maximum working pressure of the cylinder, even temporarily.

J.

isolation valves are closed.

K. Recovered refrigerant must not be charged to another refrigeration system, unless

cleaned and checked.

10. Labelling

of refrigerant. The labelling must be dated and signed. Ensure that there are labels on the

11. Recovery

- When refrigerant is removed from a system, either for service or decommissioning, it is

recommended good practice that all refrigerants are removed safely.

- When transferring refrigerant to cylinders, ensure that only suitable refrigerant-recovery

cylinders are used. Ensure that the correct number of cylinders is available to support

the total load of the system. All cylinders to be used are designated for the refrigerant

in good working order. Empty recovery cylinders are evacuated and, if possible, cooled

before recovery takes place.

-

addition, a set of calibrated weighing scales must be available and in good working order.

Hoses must be complete with disconnect couplings free of leakage and in good running

order. Before using the recovery machine, check that it is in good running order, properly

maintained, and that all associated electrical components are sealed to prevent ignition in

the event of refrigerant release. Consult the manufacturer in case of doubt.

-

recovery cylinder, and the applicable waste transfer note must be provided. Do not mix

refrigerants in recovery units and especially not in cylinders.

Loading...

Loading...