26

I

Table 2

Tube size

(mm)

Torque

(N, m)

φ 6.35 (1/4”) 15~25

φ 9.52 (3/8”) 35~40

φ 12.70 (1/2”) 45~60

Remove the maintenance panel protective covers of the indoor and outdoor units.

Loosen the terminal strip screws and properly connect the cores of the inter-unit

electrical cable and power cable to the terminals (for some models the indoor

units can be shipped with the power cable and plug already connected).

Connect the earthing wire with screws to the threaded holes located separately

on the maintenance panels. Observe the proper connection of the wires. Securely

tighten the terminal strip screws to prevent their loosening. Ensure that the

connected wires do not move by pulling on them. Fasten the inter-unit electrical

cable in the provided clamps. Reinstall the protective covers on the indoor and

outdoor unit maintenance panels.

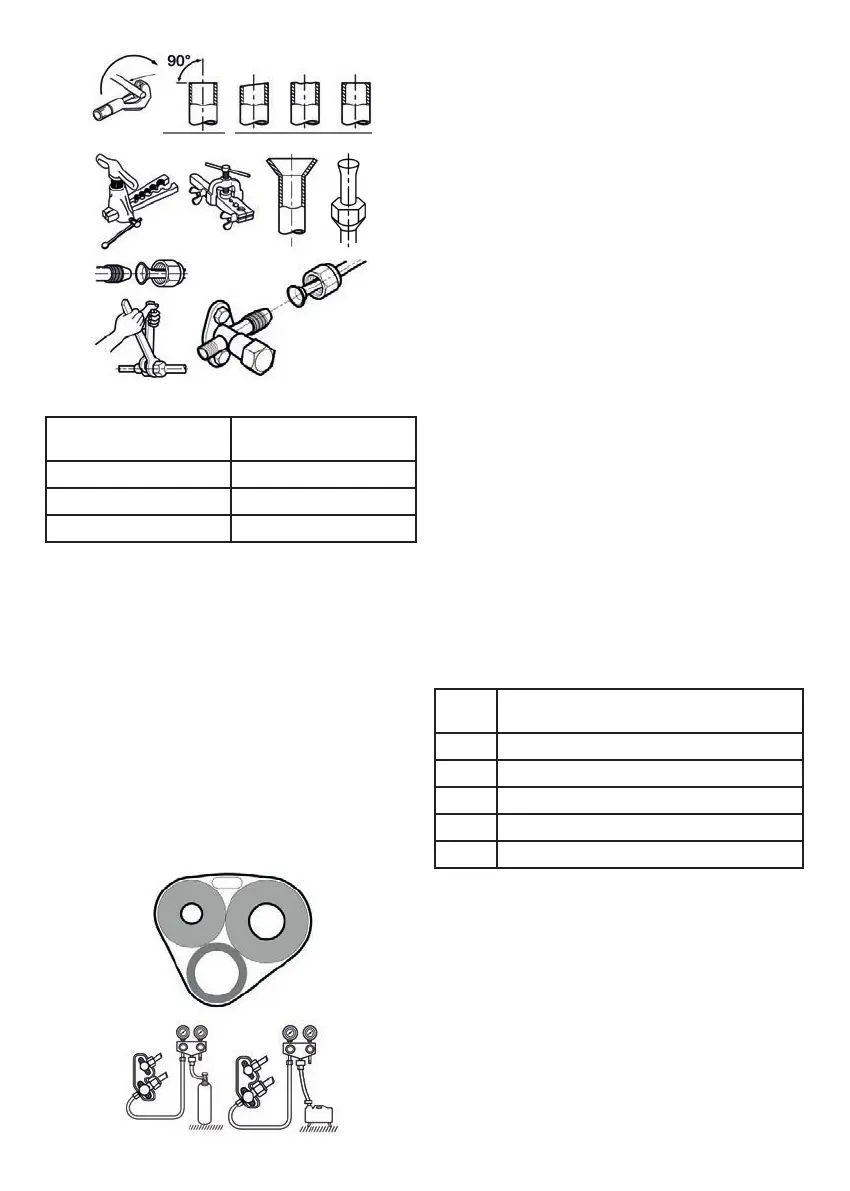

Tube Insulation and Wrapping with Tape

The refrigerant tubes should be provided with heat insulation. The refrigerant

tube connection fittings, including the outdoor unit valves should also be

heat-insulated. The drain tube, if routed indoors, should be provided with heat

insulation. Use the supplied tape to tightly wrap the refrigerant tubes, drain tube

(hose) and inter-unit electrical cable. The drain tube (hose) should be located at

the very bottom of the bundle.

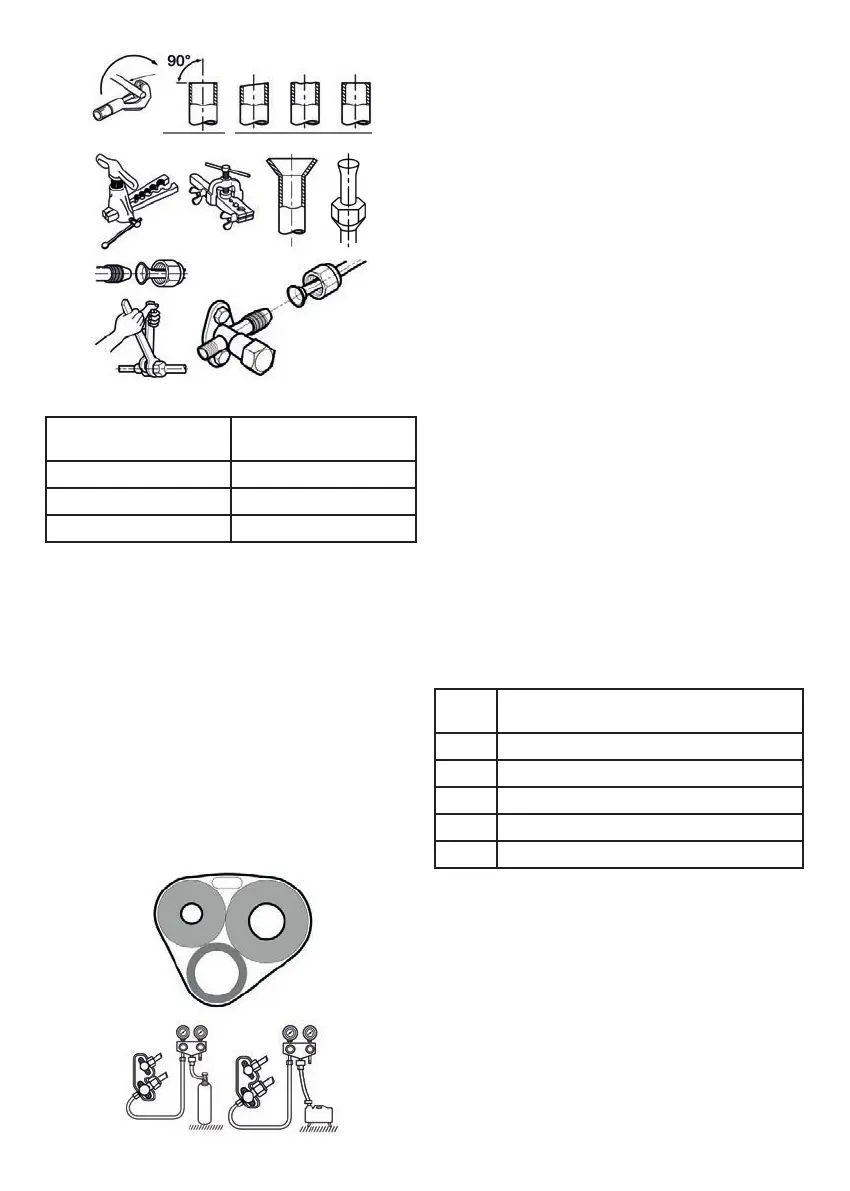

Checkup and Vacuum Testing Procedures

Ensure that the refrigerant tubes and electrical cables are properly connected.

Remove the protective caps from the gas and liquid valves in the outdoor unit

refrigerant tubes.

Ensure that the gas and liquid valves in the outdoor unit refrigerant tubes

are closed. Connect the pressure gage manifold and nitrogen bottle to the

maintenance port of the outdoor unit gas refrigerant tube. The bottle should

be connected via a pressure reducer. The use of compressed air is not allowed

because of the presence of moisture. Pressurize the system with nitrogen to 4.15

MPa. Keep the nitrogen bottle with the valve facing up to prevent liquid nitrogen

from getting into the system.

Check all pipeline connections for leaks, e.g. by applying soap suds. Repair any

revealed leaks.

Wait for 10-15 minutes and check the pressure in the system. If the pressure

drops, inspect the system to find the reason. Disconnect the nitrogen bottle from

the pressure gage manifold. Pump the nitrogen out of the system.

Connect a vacuum pump to the pressure gage manifold. Turn on the vacuum

pump. Evacuate the system to an underpressure of –0.101 MPa. Wait for 5-10

minutes and check the underpressure in the system. If the underpressure

decreases inspect the system to find that cause. Disconnect the vacuum pump

from the pressure gage manifold. Make sure that the pressure gage manifold and

vacuum pump are used properly, carefully read the operating manuals of each

device and instrument before use.

Fully open the refrigerant valves of the outdoor unit, first the liquid valve, then

the gas valve.

Disconnect the pressure gage manifold from the outdoor unit gas refrigerant tube

maintenance port. Install the protective caps on the gas and liquid refrigerant

valves of the outdoor unit.

Refrigerant Charging

These models are supplied with outdoor units charged with R410A grade

refrigerants. The systems do not require additional refrigerant charging if the

tube length do not exceed the limitations specified above.

Test Operation

Turn on AC power supply. Using the RC unit turn the AC on and check its

functionality in different modes. It should be noted that the AC efficiency test

should be performed after at least 15 to 20 minutes after the first startup.

TABLE OF FAULT CODES

Error

code

Problem

E1 Room temperature sensor fault

E2 Outdoor coil temperature sensor fault

E3 Indoor coil temperature sensor fault

E4 Indoor fan motor feedback fault

E0 Undervoltage protection

right wrong

Loading...

Loading...