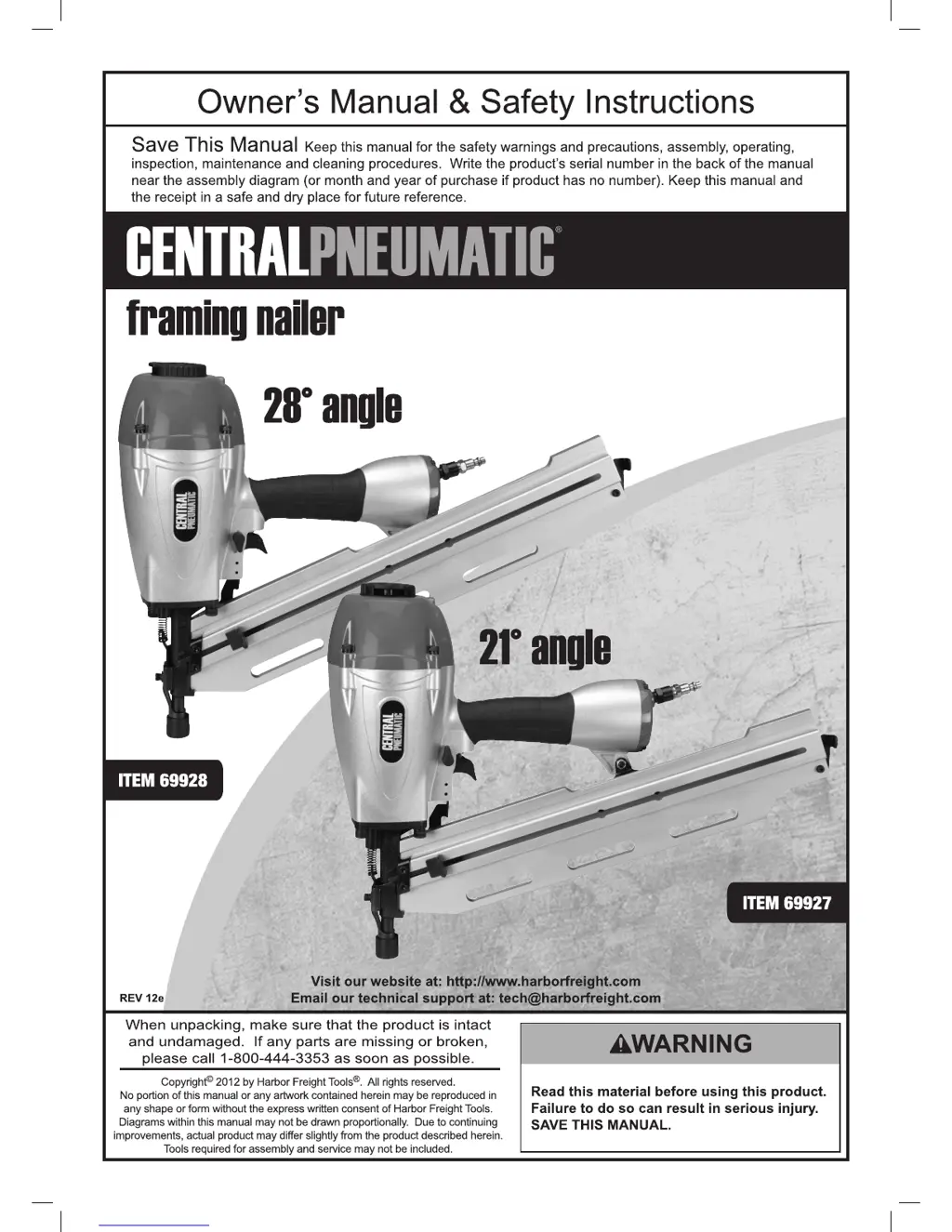

What to do if CentralPneumatic 69927 Nail Gun cycles without firing fastener?

- AAlison CabreraJul 31, 2025

If your CentralPneumatic Nail Gun cycles without firing a fastener, there might be several reasons. First, check for a jammed fastener and clear it. Ensure the tool is loaded with the correct fasteners. If the magazine is dirty or not lubricated, clean and lubricate it. Also, verify that the air supply provides enough air flow (CFM) and pressure (PSI) to the tool’s air inlet, ensuring there are no loose connections and that you do not exceed the maximum air pressure.