Centroid Acorn Plasma Users Manual Beta CNC12 v4.65 rev6

6.) Arc Voltage Calibration

An initial Arc Voltage Calibration procedure is used to configure the Plasma Torch with the CNC12 Plasma

software. This calibration must be performed before using the THC.

Prerequisites: A perfectly flat piece of metal that will not bend or move and that is laying parallel to the

torch XY movement, NOT on a slope or angle.

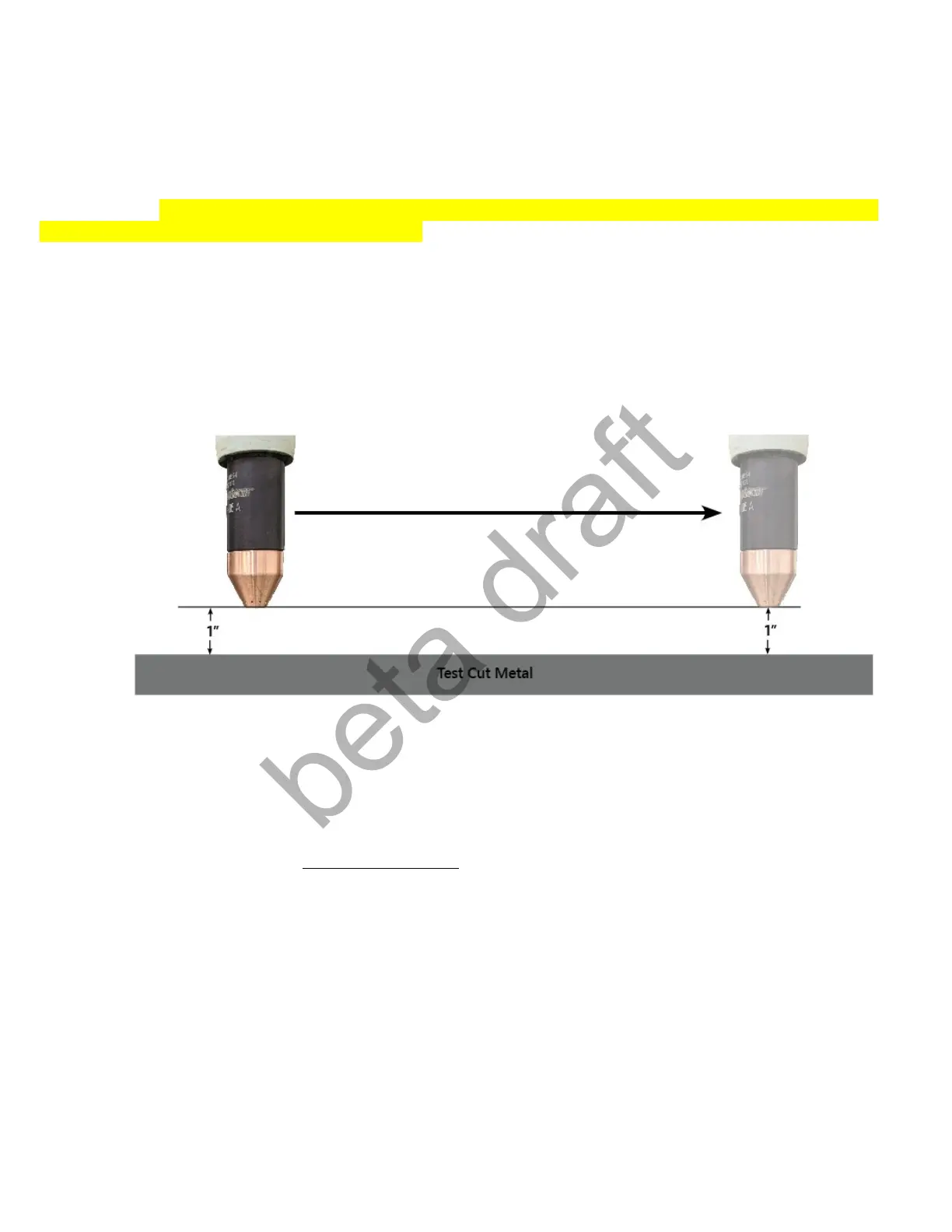

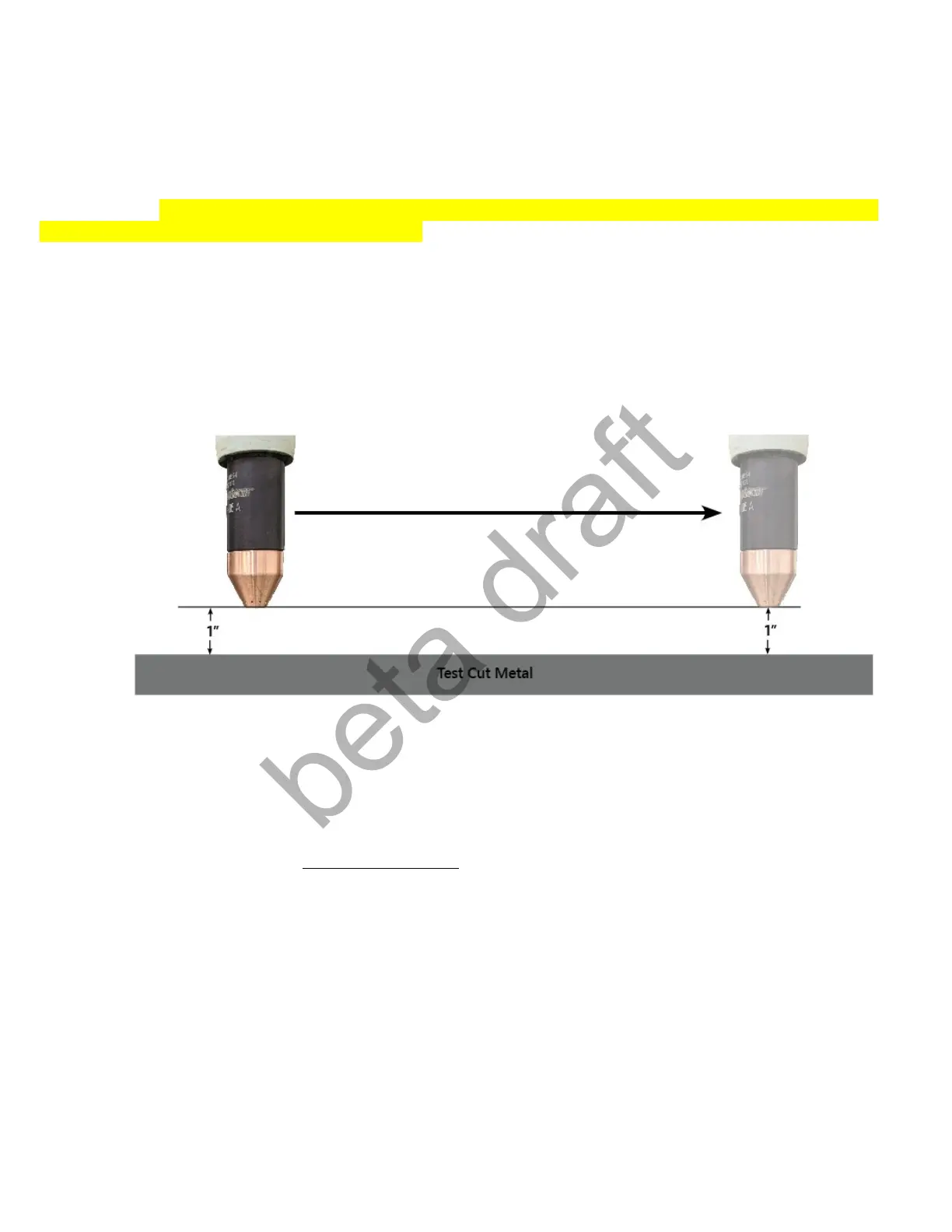

Set the test cut metal in the machine, jog the torch back and forth and make sure the metal is laying

parallel to the torch x y movement. To do this, jog Z to so the torch is 1” above the metal at one end, jog X

(or Y) to the other end of the metal and verify that the metal is still 1” away from the torch. Do the same

thing for X and Y. It is critical for this test to be conducted with a piece of metal that is flat and not on a

slope or angle. No rust, grease or paint.

Connect the ground clamp directly to the test piece of metal.

Note:

- During this calibration test the THC is NOT in use. The Z axis will stay at the fixed height during the

entire test cut.

- It is imperative that the proper material profile be used during this test. A “book” material profile that

matches not only the metal being cut but also the Plasma Unit Amp settings.

- Use a CLEAN, perfectly flat piece of metal that will not bend or move and that is laying parallel to the

torch XY movement, NOT on a slope or angle. Do not use thin metals for this test.

Page 23 D:\Keith Documents\centroid_acorn_plasma_users_manual_draft27.odt rev27 3-15-22

Loading...

Loading...