Registration

Number,

1-6

Surfaces,

4

Regulator, voltage,

2-4

aluminum,

4-2

Reverse

Polarity Contactor,

2-4,

painted,

4-2

6-2

System,

cabin

heating/ventilation,

2-5

electrical,

2-3

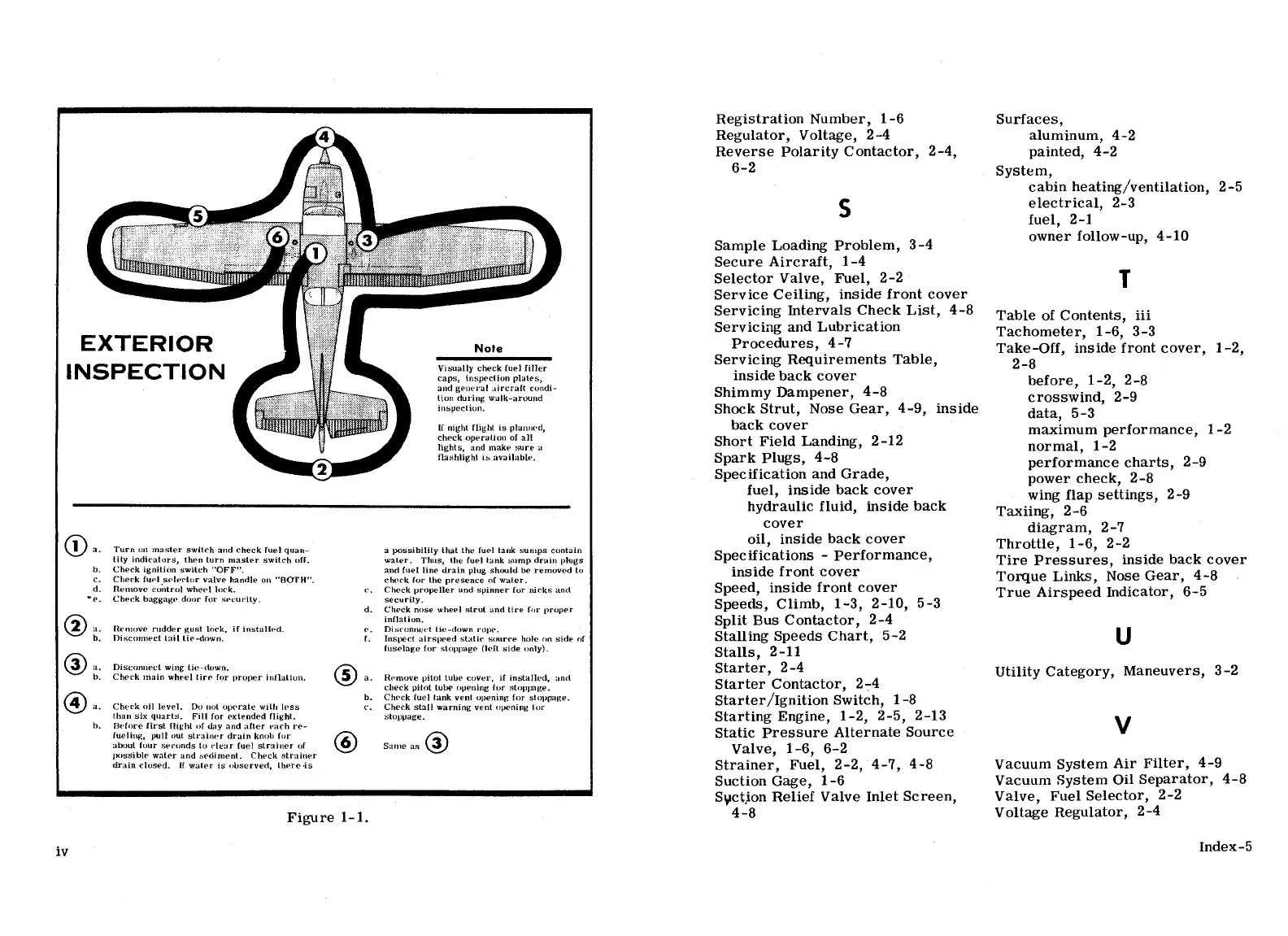

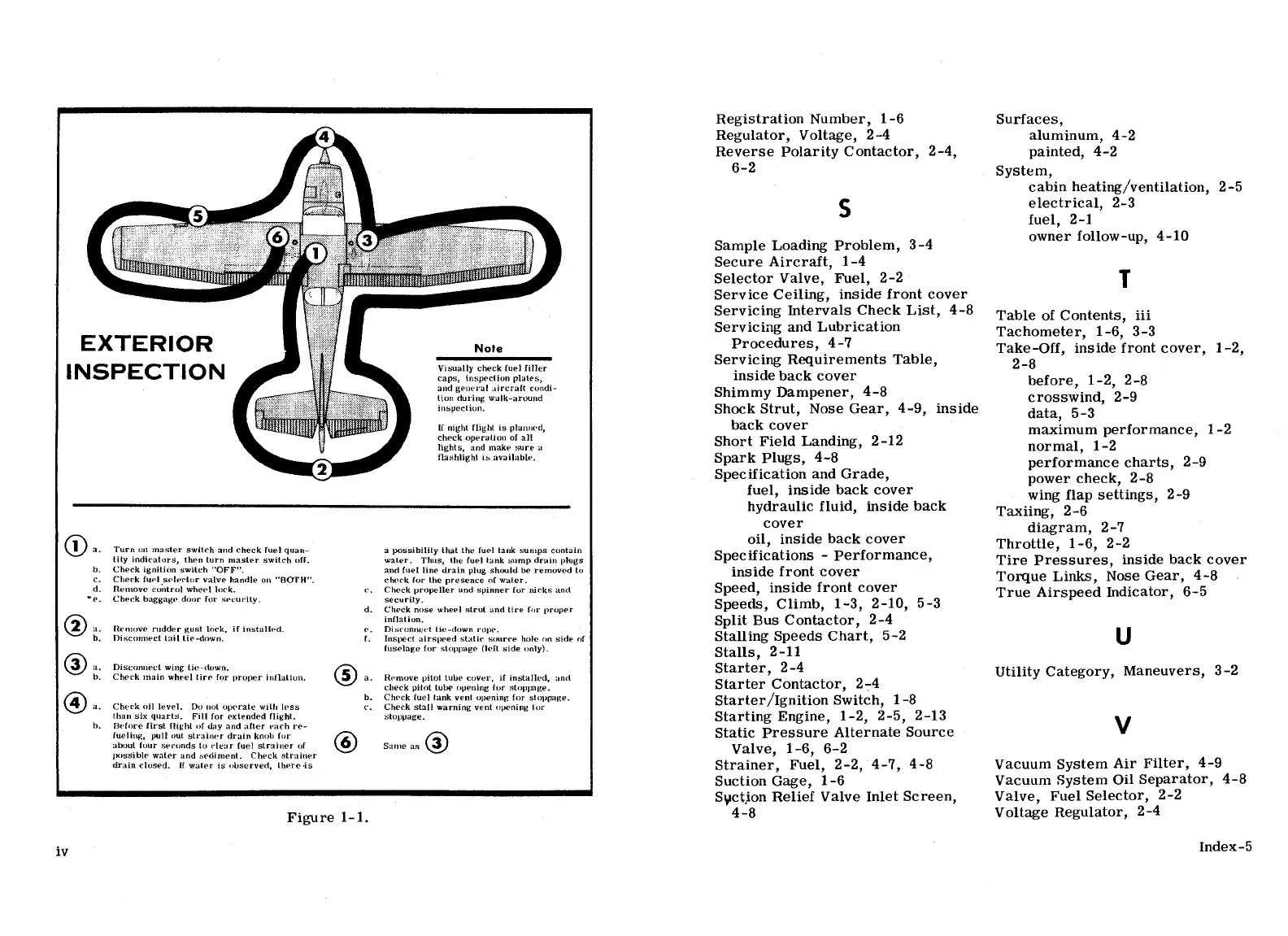

5

fuel,

2-1

6

owner

follow-up,

4-10

Sample Loading Problem,

3-4

gy

Secure

Aircraft,

1-4

Selector

Valve, Fuel,

2-2

Service

Ceiling,

inside front cover

Servicing

Intervals Check

List,

4-8

Table of

Contents, iii

Servicing

and

Lubrication

Tachometer,

1-6,

3-3

EXTERIOR

Note

Procedures,

4-7

Take-Off,

inside front

cover,

1-2,

Servicing

Requirements Table

2-8

INSPECTION

h

u

aes

inSideback cover

before,

1-2,

2-8

ud ge I

au

condi

Shimmy

Dampener,

4-8

crosswind,

2-9

nspecuen-

Shock Strut, Nose

Gear,

4-9, inside

data,

5-3

1

K night night is

planned,

back

cover

maximum performance

1-2

gÊ,°iiie°iuan

Short

Field

Landing,

2-12

normal,

1-2

flashlight is

available.

Spark

Plugs,

4-8

performance

charts,

2-9

Specification and

Grade,

power

check,

2-8

fuel,

inside back cover

wing

flap

settings,

2-9

hydraulic fluid,

inside

back

Taxiing,

2-6

cover

diagram,

2-7

oil,

inside

back

cover

Throttle

1-6

2-2

a. Turn on master

switch and

check fuel

quan-

a

possibility

that Lhe fuel tank

sumps contain

I

?

Lity

indicators, then turn

master

switch off. waLer.

Thus,

the fuel

tank

sump

drain

plugs

Specifications

-

Performance,

Tire

Pressures,

inside back cover

b. Check ignition switch

"OFF".

and fuel line drain

plug should be removed to

inSide

front cover

c. Check

fuel

selector

valve handle

on "BUTH". check for Lhe presence

of

water.

. .

TOrque

Links,

Nose Gear,

4-8

d. Remove

control wheel lock.

c, Check propeller and sµinner

for

nicks

and

Speed, mside front cover

True Airspeed

Indicator,

6-5

e. Check baggage

door for

security.

d.

seheucrk

ny<>se

wheel strut and

tire for

proper

Speeds,

Climb,

1-3, 2-10,

5-3

inna =-

Split

Bus

Contactor,

2-4

a. Hemove rudder gust

lock,

if

installed.

e. Disconnect

lie-down

rope.

b. Disconnect Lail

tie-down.

f. Inspect airspeed static

source

hole

on side

of

Stalling

Speeds Chart,

5-2

fuselage

for

stoppage

(lefL

side only)

Stalls,

2-11

iLn

e ire

on

proper

innation.

a. Remove puoi tube

cover, U

instaHed,

and

Starter,

2-4

Utility Category,

Maneuvers,

3-2

check pilot tube oµening for

stoppnge.

Starter Contactor,

2-4

a. Check oil

level. Do not operate

with

less s

llanknient oenening

>r stoµpage

Starter/Ignition

Switch,

1-8

than

six

quarts.

Fill

for extended

flight, stoppage.

Starting Engine,

1-2, 2-5,

2-13

h.

I3efore first

flight of day and after

each

re-

fueling,

pull out strainer

drain

knob for

Static

Pressure Alternate

Source

V

about four seconds

to clear fuel

sLrniner of

Same as

Valve

1-6

6-2

possible water and sediment.

Check strainer

i i

drainclosed.

Ifwaterisobserved,there.is

Strainer,

Fuel,

2-2,

4-7,

4-8

VacuumSystemAirFilter,

4-9

Suction Gage,

1-6

Vacuum System

Oil

Separator,

4-8

Syct.ion Relief

Valve

Inlet Screen, Valve,

Fuel

Selector,

2-2

Figure

1-1.

4-8

Voltage

Regulator,

2-4

.

Index-5

1V

Loading...

Loading...