English

8

Maintenance

All maintenance, cleaning and repair operations must be performed with the machine suitably supported, the engine switched off (and cool), and

the ignition keys removed.

Maintenance Schedule

After 1 hour of work

• Check all nuts and bolt for tightness – retighten if required.

• Check belt tension and taper lock tightness – adjust / tighten if required

• Grease main brush rotor bearing

Every 8 hours or daily

CHECK

• Check all nuts and bolt for tightness – retighten if required.

• Check condition in engine air filter – clean / replace as required

• Check wear and condition of brushes

• Check Oil level and top up if necessary

LUBRICATE

• Lubricate main rotor bearings – apply 20 shots of grease to each main rotor bearing

After every 100 hours (or annually, whichever occurs first), in addition to the above

CHECK

• Check belt condition - replace if required

• Check axle bearing condition - replace or lubricate as required

• Check main rotor bearings condition - replace as required

• Check condition of battery & connections

• Check condition of brushes and tines and replace as required

• Check condition of battery cables - replace if damaged

• Grease height adjustment mechanism – apply 20 shots of grease

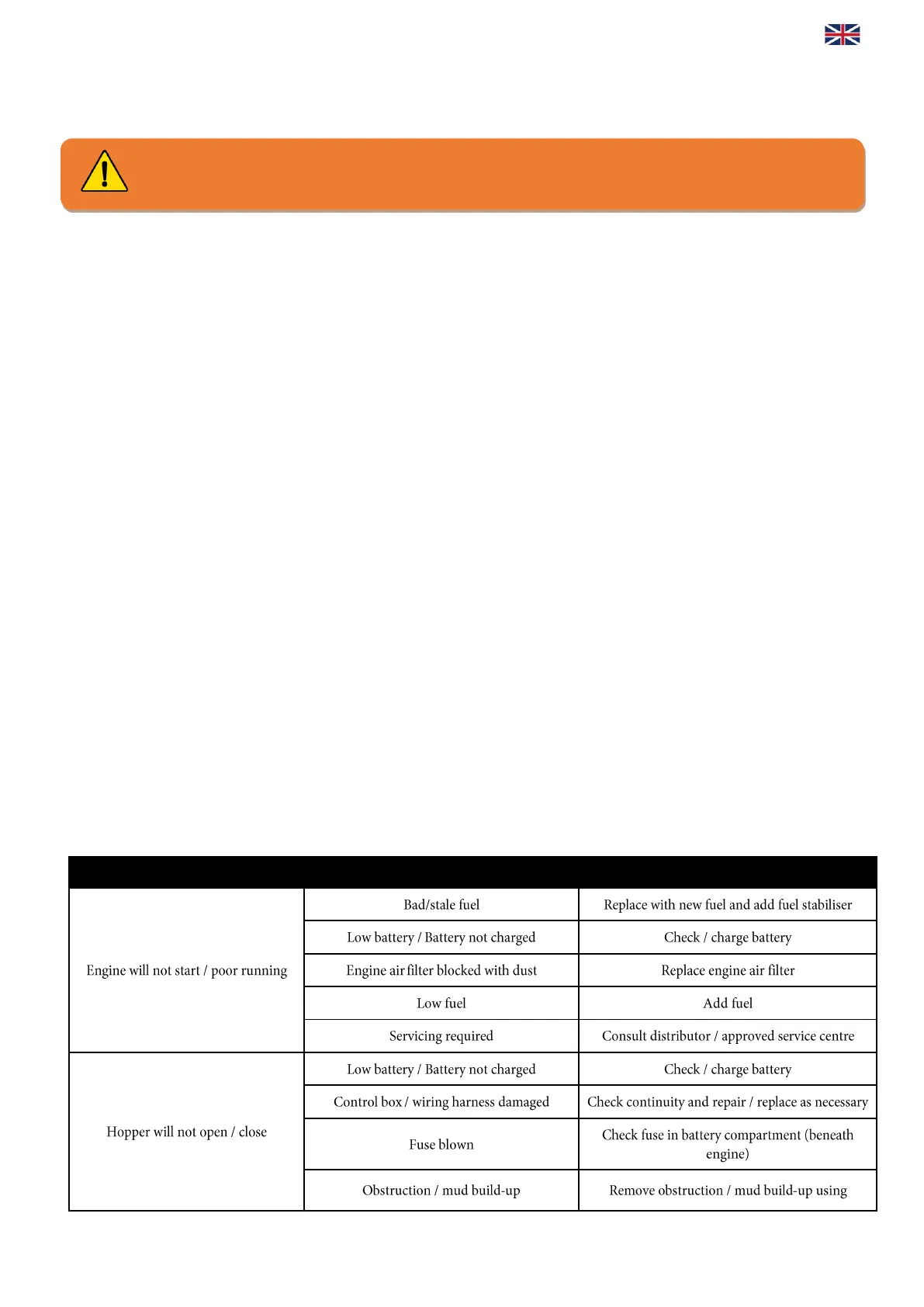

Troubleshooting

Loading...

Loading...