11/2008 Chicago Pneumatic Compressors

Page 2 62 305 549 65

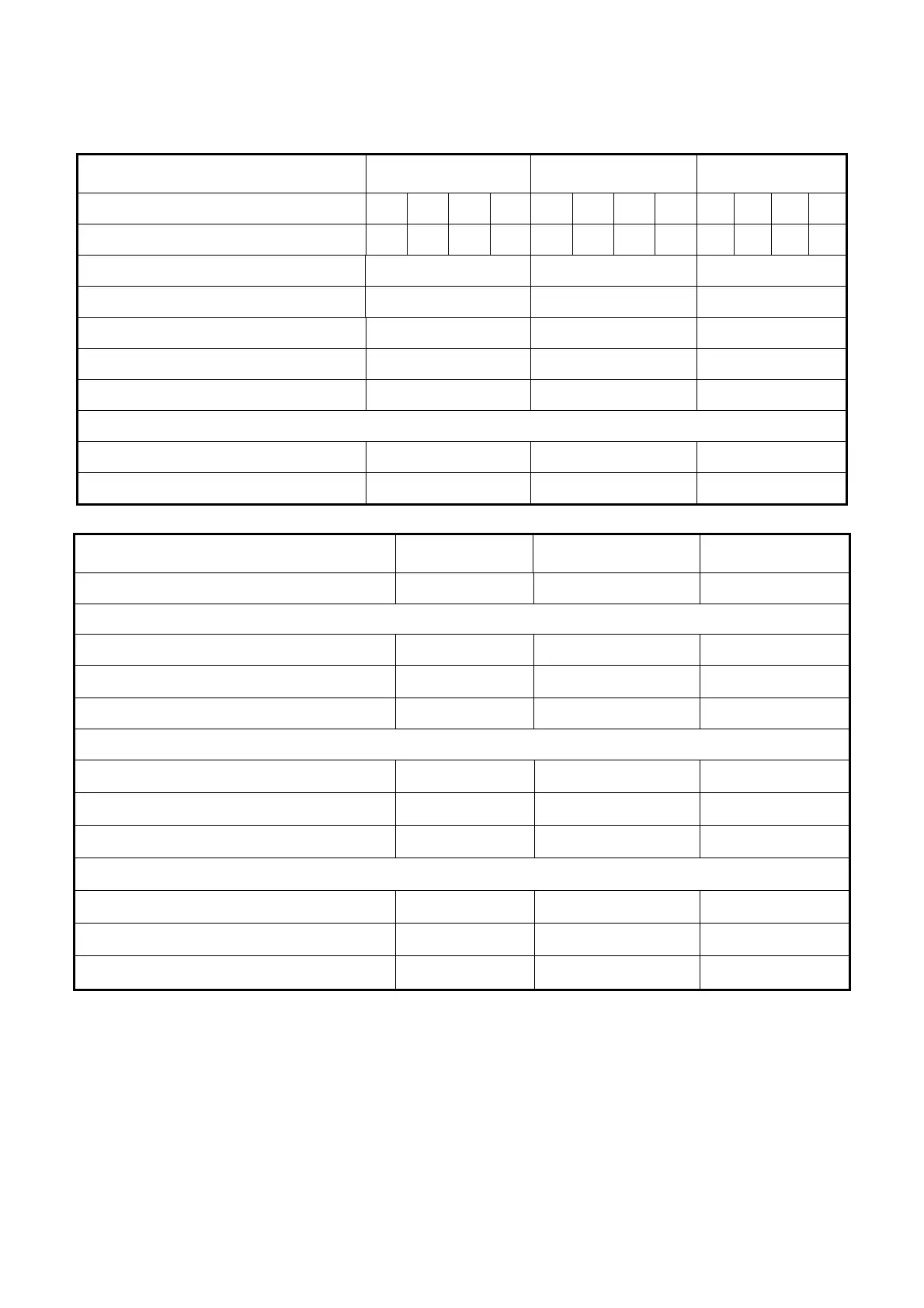

TECHNICAL DATA

STANDARD MACHINES

CPC MODEL 40 50 60

Nominal pressure at full flow

PSI 100 125 150 175 100 125 150 175 100 125 150 175

Actual flow *

(as per ISO 1217 : 1996)

cfm 166 152 137 118 208 185 164 150 268 234 209 196

Motor power hp 40 50 60

Ø Discharge orifice NPT 1.25” 1.25” 1.5”

Sound level at 3.3 ft

(as per ISO 2157 + 3 db(A))

dB (A) 73 75 73

Capacity gal 5.02 5.02 6.08

Carryover ppm 3 3 3

* Suction pressure: 14.5 PSI abs - Relative humidity: 0 % - Ambient temperature: 68 °F

- Effective discharge pressure : 102 PSI, 138 PSI or 181 PSI (effective)

Dimensions

L x W x H

43.34 x 54.77 x 60.87 43.34 x 54.77 x 60.87 43.34 x 54.77 x 60.87

Approximate weight lbs 1532 1576 1742

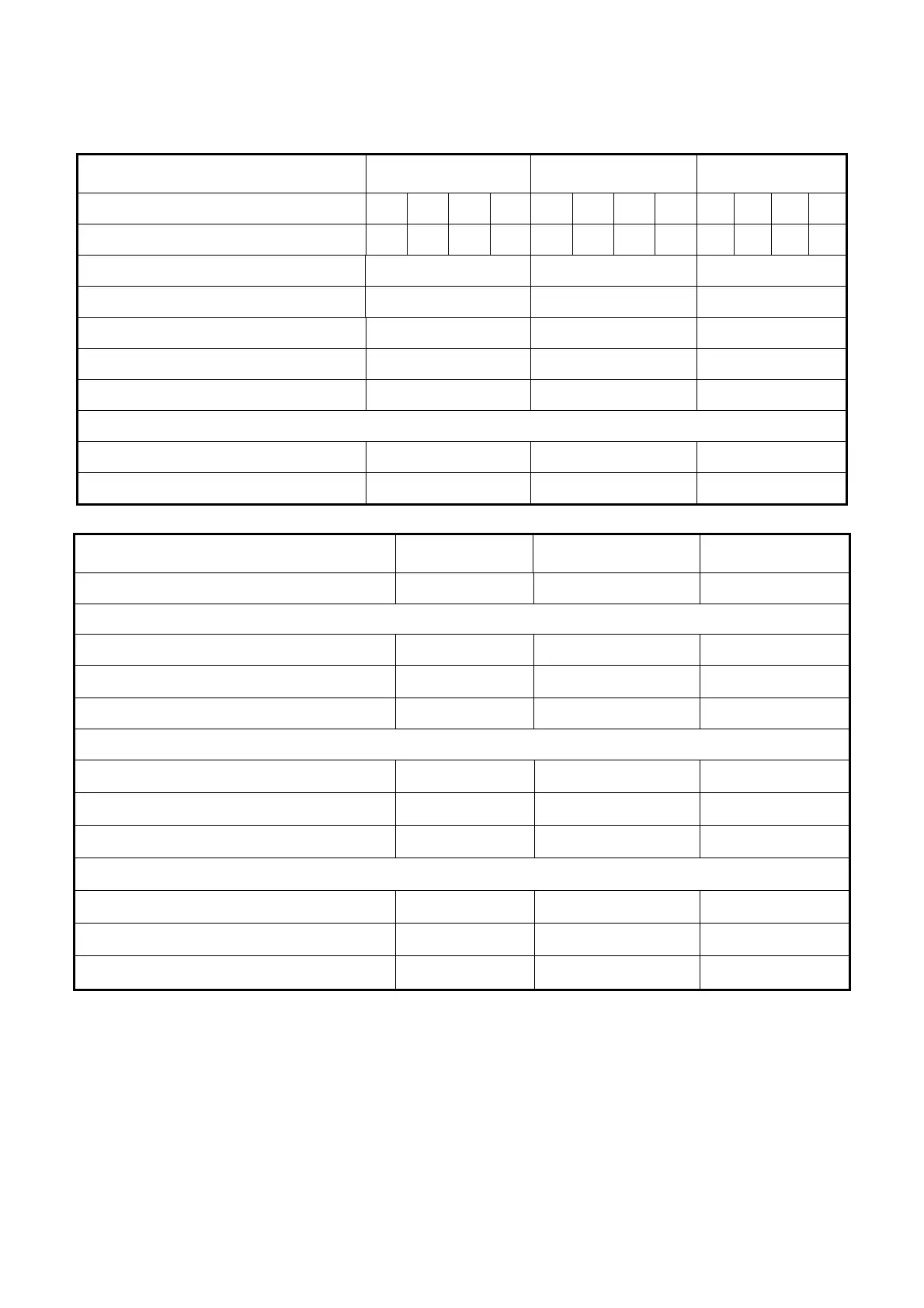

CPC MODEL 40 50 60

Motor power hp 40 50 60

Main Voltage 230 Volt / 3 / 60Hz

Nominal current

(A)

123 152 190

Power supply cable

AWG 0 AWG 00 AWG 0000

Fuse protection (RK5) 150 175 200

Main Voltage 460 Volt / 3 / 60Hz

Nominal current

(A)

66 79 100

Power supply cable

AWG 0 AWG 00 AWG 0000

Fuse protection (RK5) 80 100 125

Main Voltage 575 Volt / 3 / 60Hz

Nominal current

(A)

46 57 71

Power supply cable

AWG 6 AWG 4 AWG 3

Fuse protection (RK5) 50 70 80

Connection of the electric plate to an external control box

• Install an RC filter on the KM1 coil.

• Install an RC filter on the KM2 coil.

• All connections between external parts and the compressor must be carried out using a shielded cable, which must be

grounded at one of its ends.

WARNING: the operation connection cables between the different elements must never follow the same path

as the existing power cords. A separate installation from the power cords must be carried out.

• Install an RC filter on all the relay coils of the external operation units.

Loading...

Loading...