3130

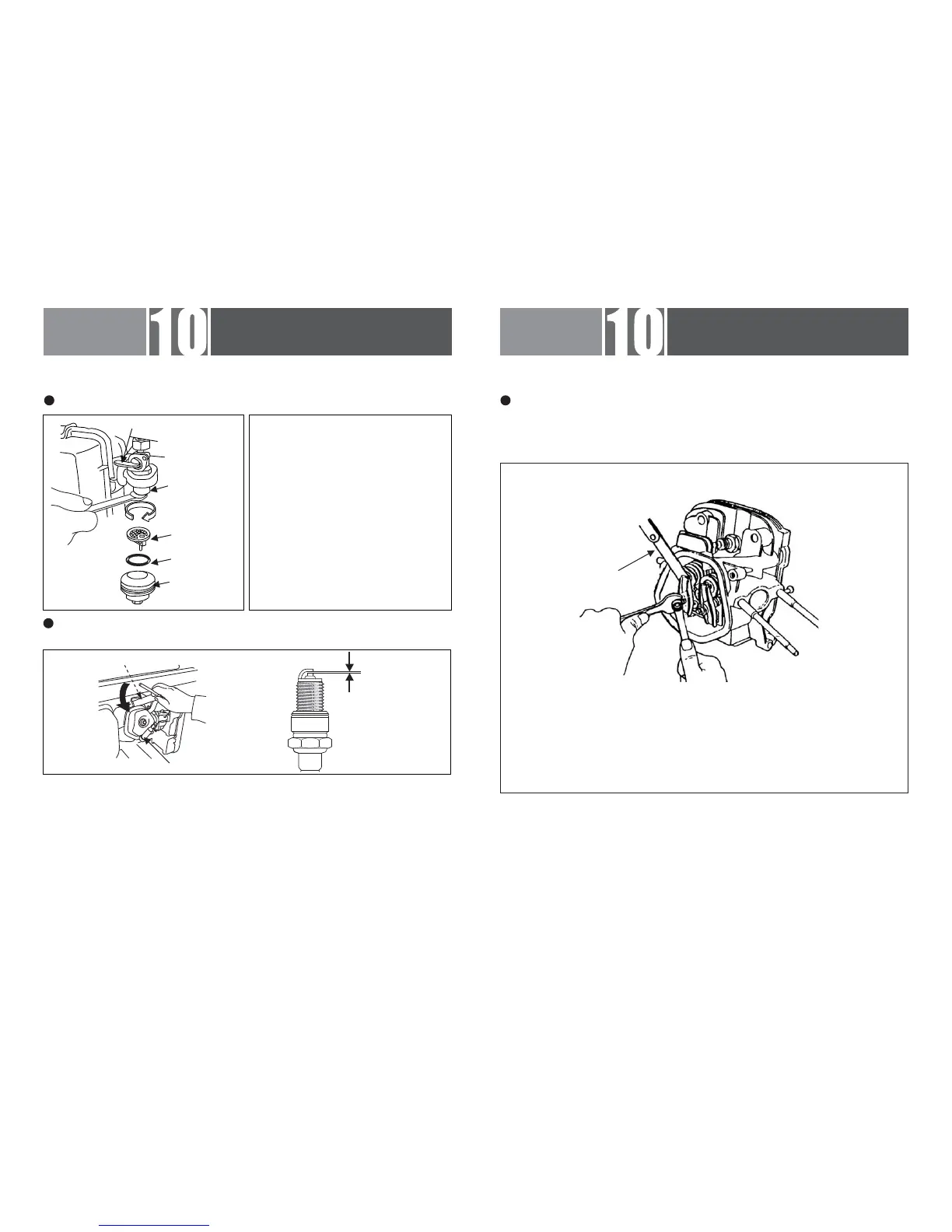

Clean the fuel valve lever sediment cup

Sediment cup

O-Ring

Fuel filter

Sediment cup

Fuel valve

1. Close the fuel valve and remove

the sediment bowl. Take out the

O type seal ring and strainer.

2. Clean the sediment bowl, O

type seal ring and strainer with

incombustible or high flash

solvent.

3. Reinstall the O type seal ring

and strainer, and tighten the

sediment bowl

4 Open the fuel valve and inspect

for leakage.

-

-

-

-

.

.

Clean the spark plug

Recommended spark plug models F7RTC and F7TC:

1 Remove the spark plug cap.

2 Clean the spark plug base.

3 Remove the spark plug with the spark plug socket spanner.

4 Inspect the spark plug insulator visually for damage. If it is damaged

replace a new one.

5 Measure the spark plug gap with a gap gauge. Twist the side electrode

to adjust the gap.The gap should be kept between 0 70 and 0 80mm.

6 Inspect if the washer of the spark plug is in good condition.

7 Reinstall the spark plug and tighten it with the spark plug socket spanner.

Press down the washer of the spark plug and place the spark plug cap.

,

..

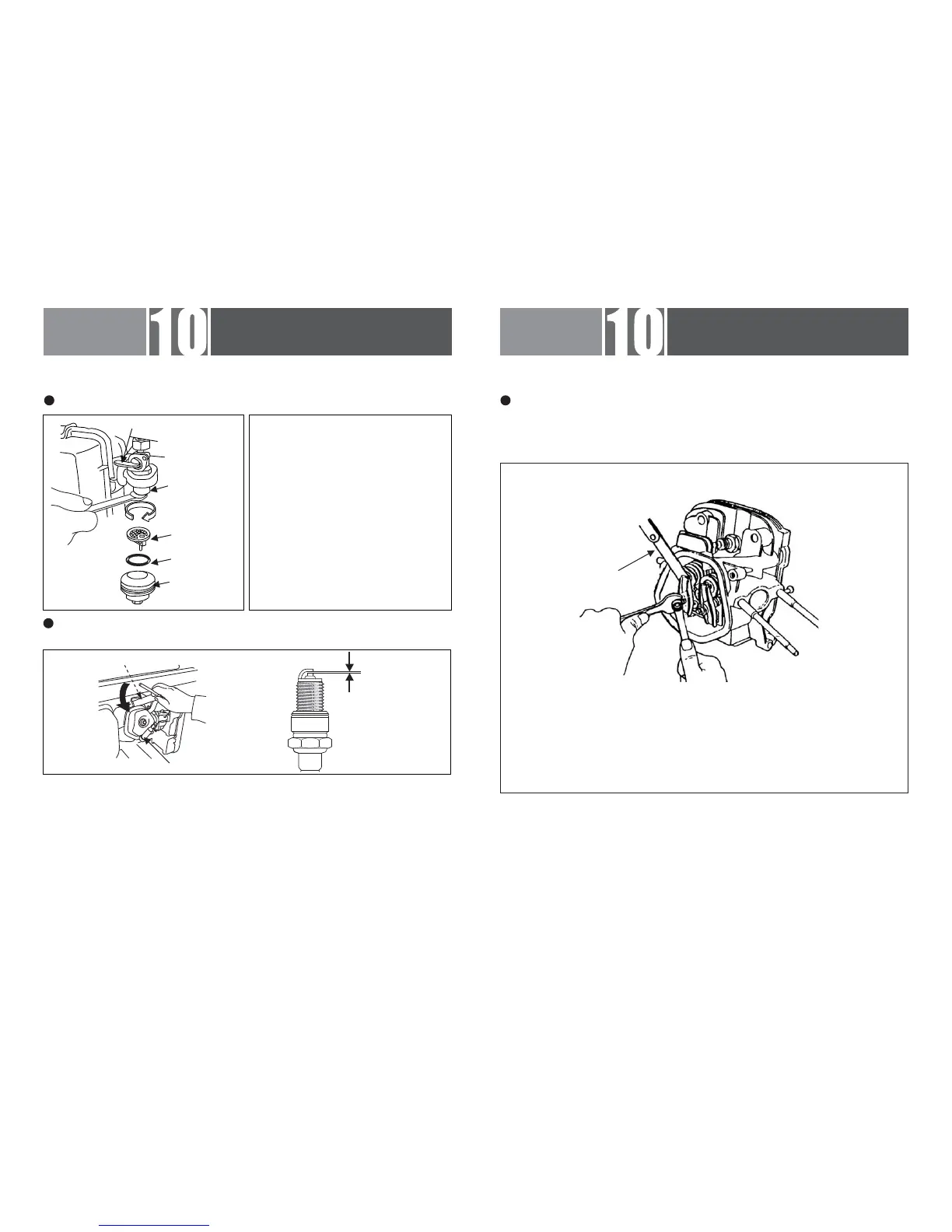

Valve clearance

(should be conducted by a professional person)

Figure 1 applicable to CPPG2.3 / CPPG2.5 / CPPG5 CPPG5T CPPG5.5.

//

0.70-0.80mm

Spark plug

wrench

Spark plug cap

Feeler gauge

Remove the cylinder head cover and measure the valve clearance with

the feeler gauge. The clearances are 0 1mm for the inlet valve and

0 15mm for the outlet valve.

.

.

Figure 1

Portable Gasoline Generator Operating Instructions

Maintenance

Portable Gasoline Generator Operating Instructions

Maintenance

Loading...

Loading...