16 Operating Instructions

7 PLATE HEAT EXCHANGER (OPTION)

Cleaning of plate exchanger

Soldered heat exchanger: For the removal of lime- and rust deposits, purifying agent SWEPcip AS, RS, CS or

S (according to material) is suitable. Cleaning may be performed by means of SWEP cleaning device C.I.P 90

(circulation method) or a stationary pump.

Screwed heat-exchanger: In this case the heat exchanger can also be disassembled for cleaning.

See attached concept for further technical data

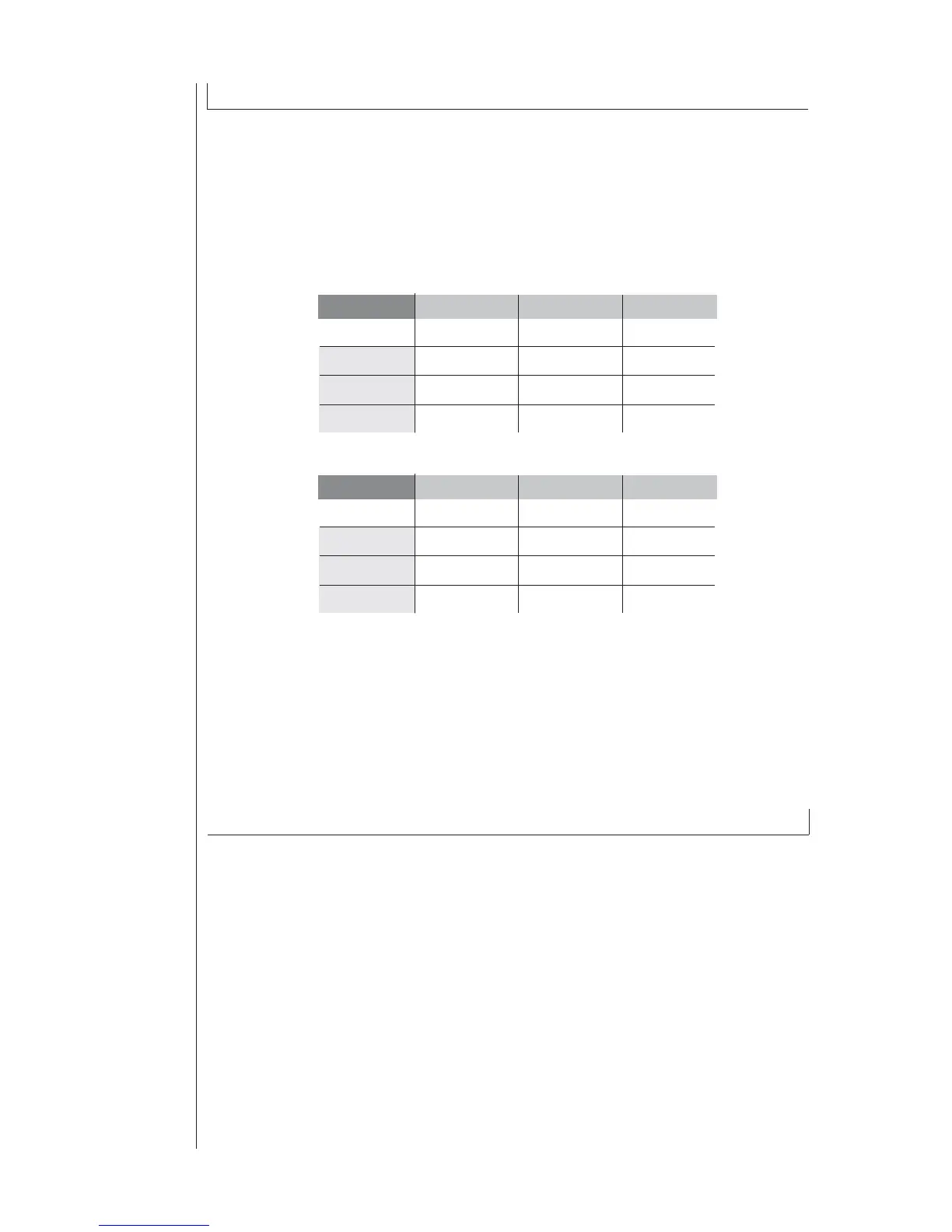

Stainless steel

Lime Rust Lime + Rust

SWEPcip AS SWEPcip CS SWEPcip AS

Max. Temp: 80 °C 80 °C 80 °C

Max. time: 8 h 8 h 8 h

Mixture ratio: 1:10 1:5 1:10

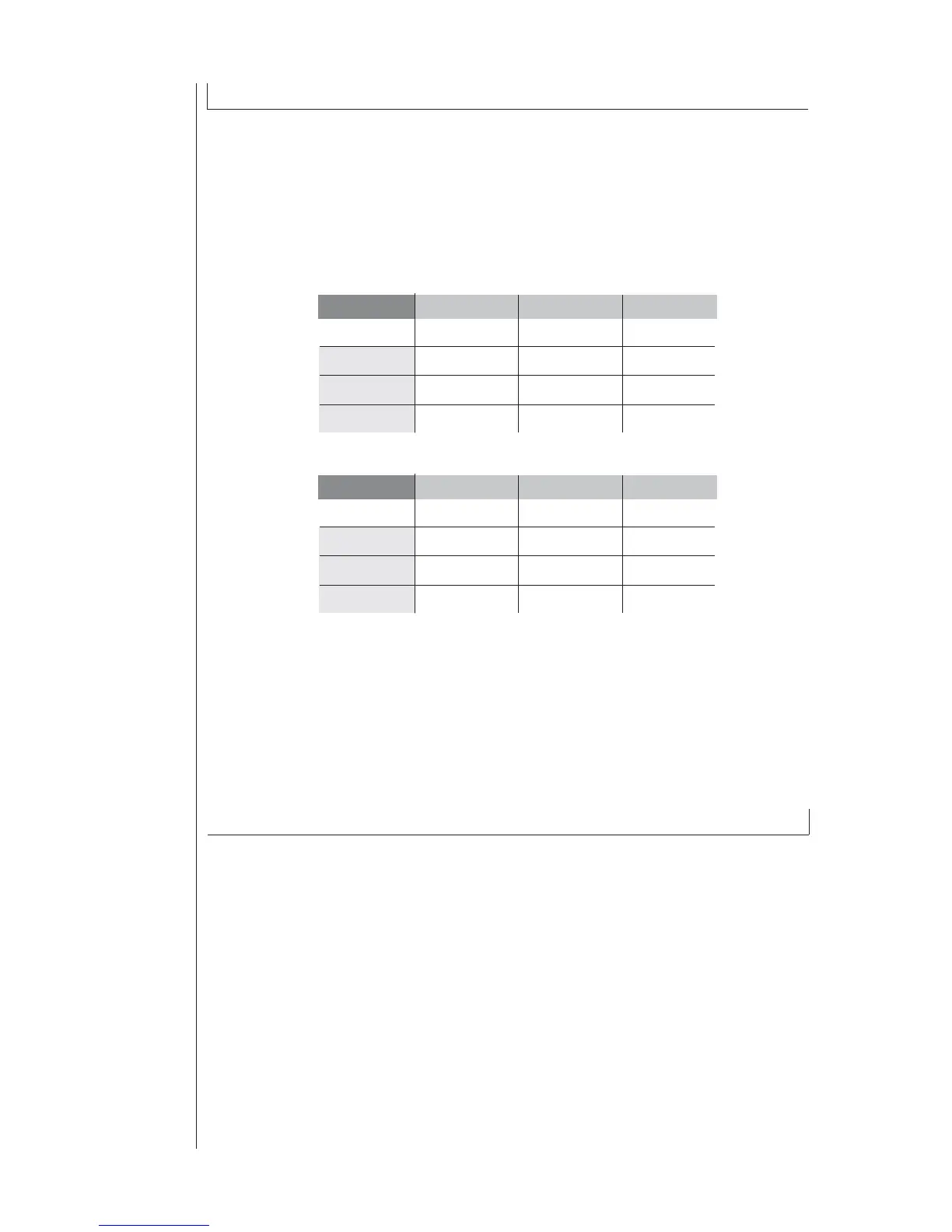

Steel Lime Rust Lime + Rust

SWEPcip AS SWEPcip RS SWEPcip S

Max. Temp: 80 °C 80 °C 50 °C

Max. time: 8 h 8 h 8 h

Mixture ratio: 1:10 1:5 1:5

8 Waste disposal

The refrigerant cycle of the chiller contains an enviroment friendly refrigeration fl uid. Only registered and quali-

fi ed refrigeration companies are permissible to carry out work on the chiller. Before attending any repairments or

maintanance work on the refrigeration cycle the refrigerant must be recovered by means of a recovery unit. Any

intention blowing off the refrigerant is prohibited. Disposal of the refrigerant and any other parts like compressor

oil or waste water must be completed according to local regulations only.

Specifi cation subject to change.

Loading...

Loading...