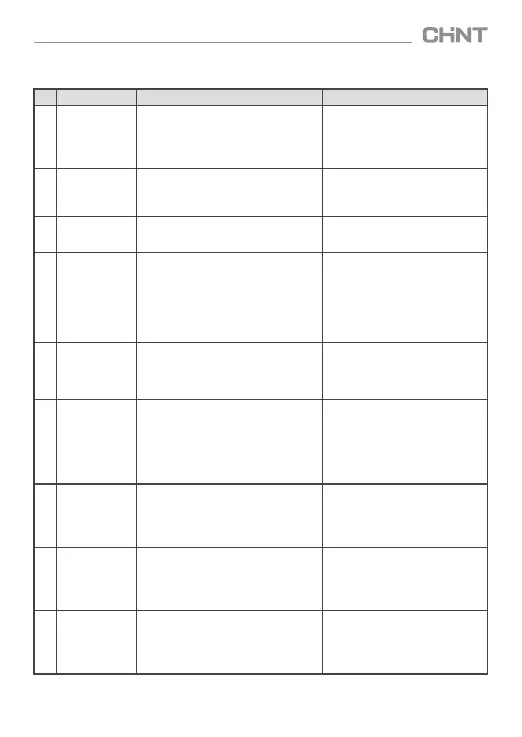

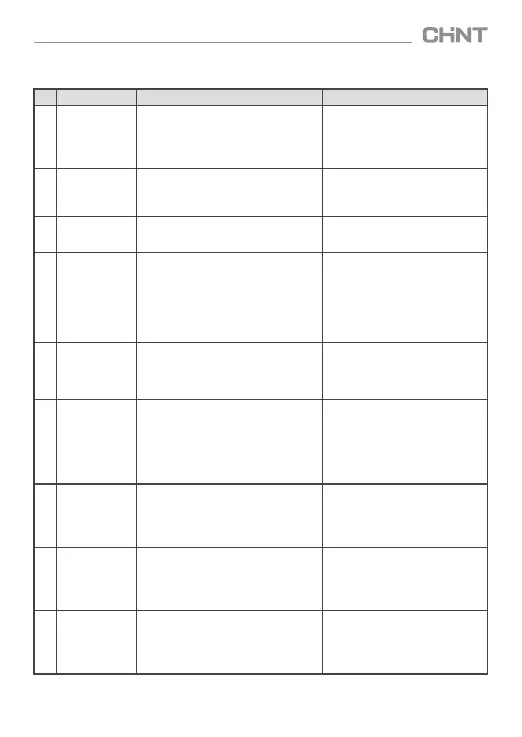

Table 5 Analysis and troubleshooting of faults

No.

Faults

Cause analysis

Solutions

1

Load equipment is

turned on, but the

controller still

displays

undercurrent “≡1”

1. The sampling current is smaller than

150mA or the secondary circuit of the

current transformer is open;

2. Fault exists in the current transformer

or the controller.

1. Check if the secondar y circuit of the

sampling current transformer is open;

2. If the measured IS1 and IS2 sampling

currents are bigger than 200mA,

replace the controller.

2

Sometimes the

controller

displays“≡0”

Current transformer sampling current is

bigger than 6.0A, which means the

selected sampling current transformer

ratio is too small.

Select CT based on the primary current

of current transformer is larger than

load current.

3

Controller always

displays “≡U”

or voltage value

1. Undervoltage or over voltage alarm,

display this code;

2. Product fault

Test voltage before increasing set

overvoltage threshold. If the increase

is invalid, replace the product.

4

The displayed

power factor keeps

changing, or the

leading and

lagging indicator

keep switching.

1. Load is relatively low and sampling

current is smaller than 200mA;

2. Caused by frequent load change,

such as electric welding machine,

spot-welder, rolling mill, pressing machine,

hauling equipment;

3. Electrical load is not stable; transformer

load rate is relatively low.

1. Turn on motor load and observe the

display of the controller;

2. Select dynamic reactive power

compensation equipment for fast

changing load;3. Select controller

that uses non-isometric optimal

switching, such as NWK1-GR liquid

cr ystal controller.

5

Af ter adding

capacitors, the

power factor

remains almost

the same.

The installation position of the current

transformer is wrong; the primary current

is not included in the cabinet.

Take total current: sampling current

=load current + capacitor current,

which means the primar y line of the

cabinet is connected after the

sampling transformer.

6

No matter what

load, the controller

always displays

leading, the power

factor is negative,

and the system

does not operate

automatically.

1. Wrong sampling phase sequence, such

as phase A for current, and phase AB for

voltage;

2. There is equipment such as frequency

converter or rectifier installed at load

end, which causes harmonic interference.

1. Determine sampling phase

sequence according to 7.3.4;

2. Select NWK1-GR liquid crystal

controller with stronger anti-

harmonic interference capability.

7

Capacitor

switching is too

frequent

1. Fast change of load current, the set

delay time is shorter than 10s;

2. The set target power factor is too low;

3. The set reactive power threshold is

too low.

1. The set delay time is longer than

30s;

2. Increase target power factor;

3. Increase reactive power threshold

properly.

8

The displayed

power factor is

lower than 0.90,

but no capacitor

is added

automatically.

1. Load is relatively low, the required

reactive power Qs is smaller than set

value of F-1 reactive power threshold;

2. The set transformer ratio is too small.

1. Recommend to replace with 2

groups of capacitors with smaller

capacity;

2. Set transformer ratio correctly;

9

The controller

displays garbage

characters or the

controller is

crashed.

1. Abnormalities such as lightning strike;

2. Electromagnetic interference。

Disconnect the power and restart the

machine. If the problem occurs

repeatedly, replace the product.

JKF8 SeriesSmart Low-Voltage Reactive Power Compensation Controller

08

Loading...

Loading...