Ŷ *URPPHW

Ŷ 3LSHJURPPHW

Ŷ HOERZVIRUSUHVVXUHWDSSLQJ

Ŷ 3ODVWLFSOXJVIRUSURWHFWLQJVFUHZV

Ŷ (OHFWULFDOZLULQJ

Ŷ $QWLYLEUDWLRQPRXQWVIRUIDQV

7KHVHFRPSRQHQWVFDQEHUHPRYHGDQGUHSODFHGLQWKHHYHQWRIPLFURELDORUIXQJDOLQIHFWLRQ,WLVUHFRPPHQGHGWKDWWKH\EH

UHSODFHGHYHU\PRQWKV

$VWKHFDEOHVDUHQRWELRORJLFDOO\LQHUWWKH\PXVWEHPRQLWRUHGFORVHO\DQGEHVXEMHFWWRIUHTXHQWFOHDQLQJ6KRXOGDGHIHFWEHFRPH

DSSDUHQWKDYHWKHVHUHSODFHGE\WKHDXWKRULVHG87&6HUYLFHWHDPV

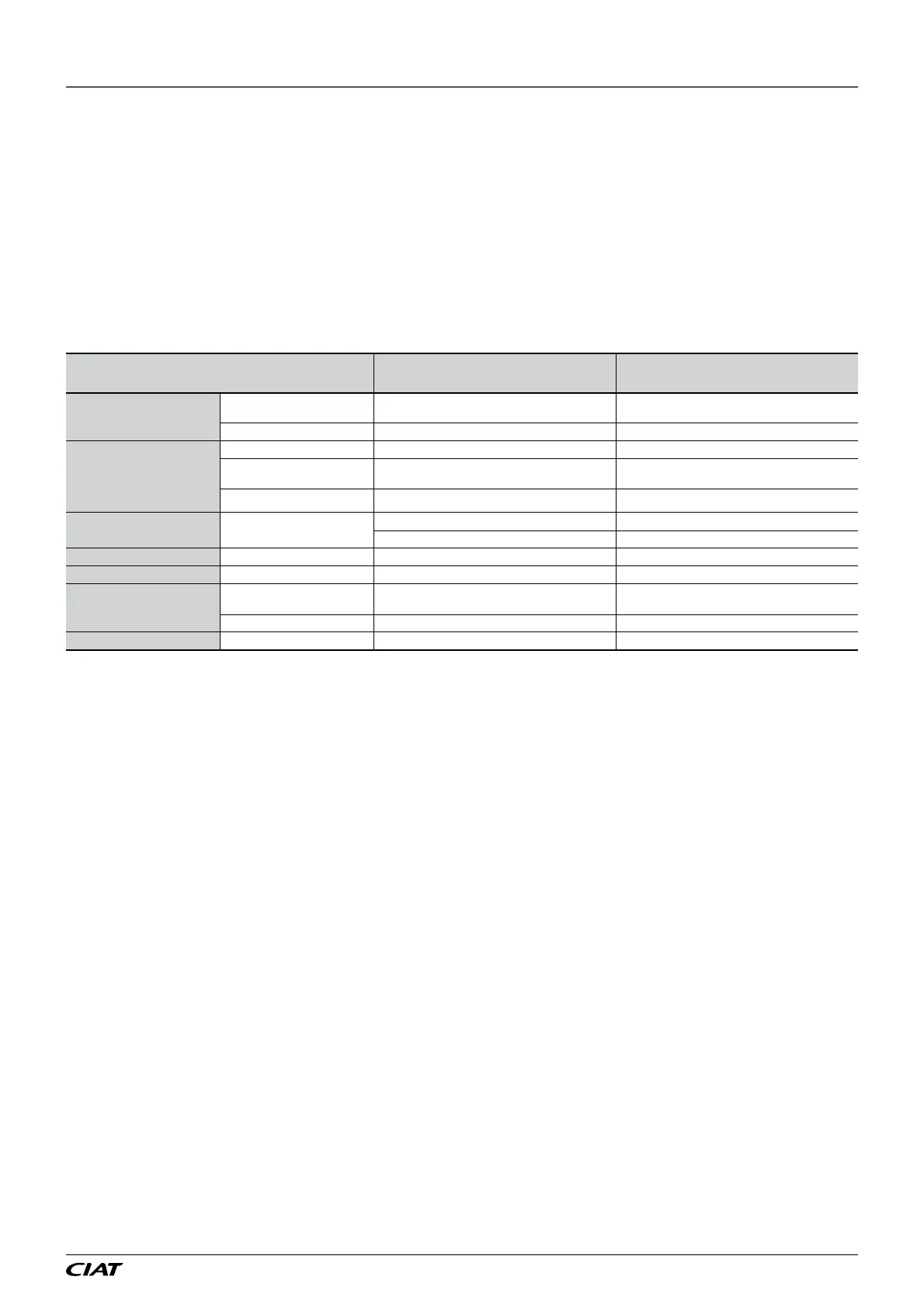

10.12 - 3URORQJHGGRZQWLPH

Components Perform before or during prolonged downtime Perform after prolonged downtime

Fan

Bearings

0RQWKO\URWDWLRQWRSUHYHQWWKHIRUPDWLRQRIÀDW

areas on the treads

Belts Slacken the belts Alignment and tension

Motor

Motor Retighten the electrical connections

Roller bearing

0RQWKO\URWDWLRQWRSUHYHQWWKHIRUPDWLRQRIÀDW

areas on the treads

Cooling grille Check the cooling grille cleanliness

Water coils

Drain or add glycol

Bleed the air

Siphon

Drain Fill

Registers

Dampers Check for hard points in the rotation

Rotary heat exchanger

Bearing

0RQWKO\URWDWLRQWRSUHYHQWWKHIRUPDWLRQRIÀDW

areas on the treads

Belt Check tension

+XPLGLÀHU

Check the condition of the cylinder

10 - OPERATION AND MAINTENANCE

(1 &/,0$&,$7

®

Loading...

Loading...