22-11

Page 12

All

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODELS SR22 AND SR22T

15 Jun 2010

(d) Serials 22-0498 thru 22-1367: Using rigging lockout tool and pin, lockout elevator empen-

nage bellcrank.

(e) Using tensiometer, verify elevator control cable tension. If elevator control cable tension

falls outside specified tolerance, perform Adjustment/Test - Elevator System Rigging.

(Refer to 27-30) (Refer to 27-30)

(f) On servo capstan, position bridle cable stop-ball between 11 o’clock and 1 o’clock posi-

tions (stop-ball at top of capstan).

(g) Position aft bridle cable and clamp assembly to outboard elevator cable and loosely

secure with bolts and nuts.

(h) Position forward bridle cable and clamp assembly to outboard elevator cable and loosely

secure with bolts and nuts.

Note: Use a ratcheting open-end wrench and socket for tightening bridle cable

clamp assembly to elevator cable.

(i) At forward bridle cable clamp assembly, push clamp assembly forward, tighten clamp to

elevator cable.

Note: While tightening bridle cable clamp to elevator cable, capstan will rotate.

Offset this rotation while adjusting opposite bridle cable tension so that

when specified tension is reached, the bridle cable stop-ball is between 11

o’clock and 1 o’clock positions (stop-ball at top of capstan).

(j) At aft bridle cable clamp assembly, push clamp assembly aft while tightening clamp to ele-

vator cable.

(k) Using the techniques described above, adjust bridle cable tension to 17.0 ± 4.0 lb (7.7 ±

1.8 kg).

(l) Serials 22-0002 thru 22-0497: Remove lockout pin from elevator actuation pulley.

(m) Serials 22-0498 thru 22-1367: Remove rigging lockout pin and tool from elevator empen-

nage bellcrank.

(n) Install access panel RE1. (Refer to 06-00)

(7) Adjustment/Test - Bridle Cable Tension - Serials 22-1368 & subs, 22T-0001 & subs

(a) Acquire necessary tools, equipment, and supplies.

(b) Remove access panel RE1. (Refer to 06-00)

(c) Using rigging lockout tool and pin, lockout elevator empennage bellcrank.

(d) Using tensiometer, verify elevator control cable tension. (See Figure 06-001) If elevator

control cable tension falls outside specified tolerance, perform Adjustment/Test - Elevator

System Rigging. (Refer to 27-30)

(e) On servo capstan, position bridle cable stop-ball at 3 o’clock position (stop-ball at back of

capstan).

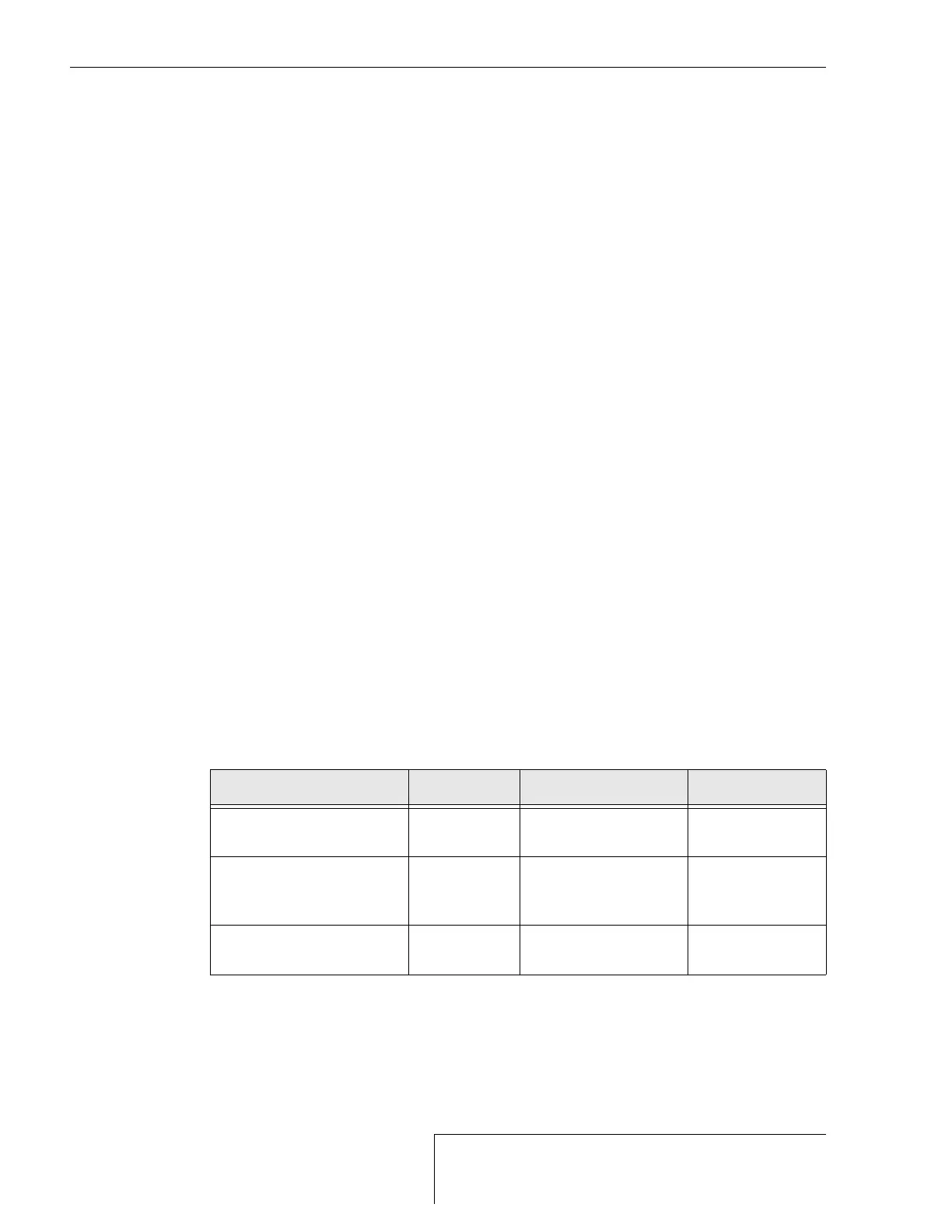

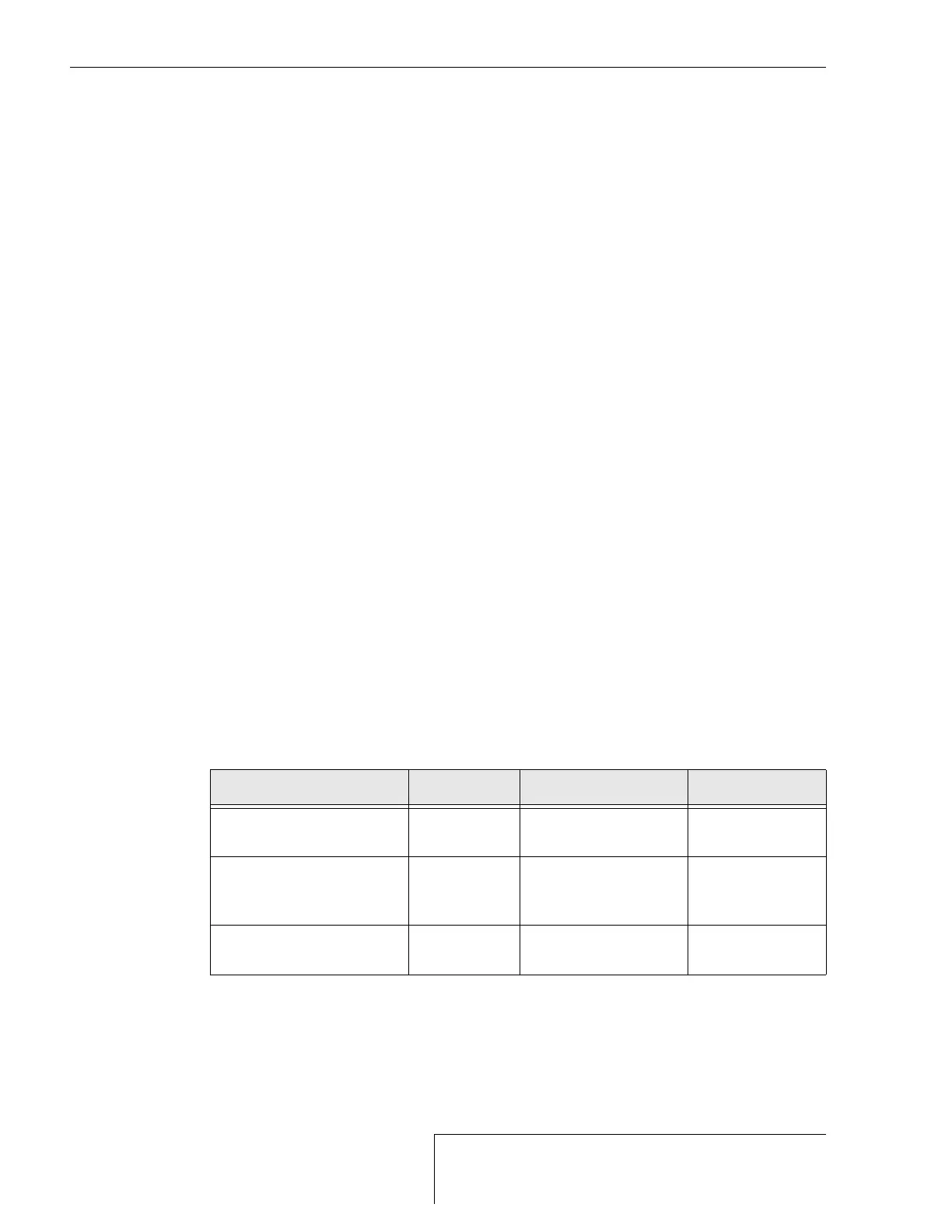

Description P/N or Spec. Supplier Purpose

Tensiometer BT-33-75D Kent Moore

Warren, MI 48092

Cable tension

determination.

Rigging Lockout Tool 14905-001 Cirrus Design

Duluth, MN 55811

218-727-2737

Lockout elevator

bellcrank.

3/16” Lockout Pin - Any Source Lockout elevator

bellcrank.

Loading...

Loading...