Cirrus Users Guide V26.docx Page 22 of 23 Printed 10/10/16

Unscheduled/Emergency Maintenance

There are a number of issues that may occur and there are some “Tricks” that make

repairing them easier.

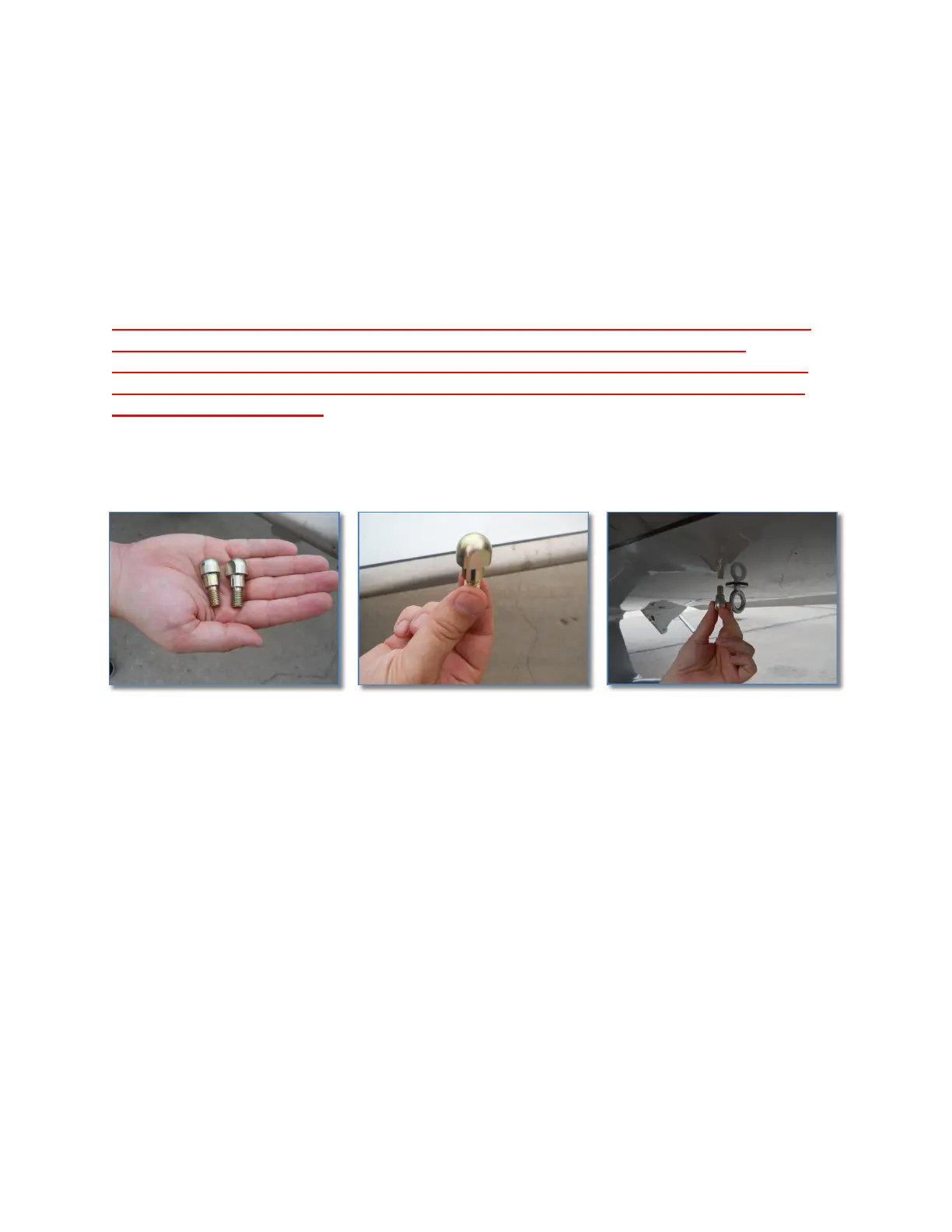

Flat Tire: If the aircraft requires jacking up, make sure you remove the tie-down eye bolt

from the jack point screw and replace it with the one of the jacking lugs which are

usually kept in the center console or the storage pocket inside the rear baggage door.

UNDER NO CIRCUMSTANCES SHOULD YOU JACK ON THE TIE-DOWN RINGS.

THE RING MAY SLIP OFF OR IT WILL WILL SNAP AND THE JACK WILL

PUNCTURE THE WING AS IT FALLS! ALSO, JACK BOTH WINGS EVENLY NOT

JUST ONE SIDE. THIS ALSO AVOIDS THE NOSE WHEEL ROTATING AND THE

JACK POINT SLIPPING!

If the jack lugs are unavailable, simply remove the tie-down rings and replace them with

a standard bolt of the same thread size.

Dead Battery or Stuck Starter: These can be simple fixes, but be aware of some

issues if you have to remove the cowling.

• Protect the prop spinner and the windshield. It’s very easy to scratch the polished

or painted prop spinner when removing or reinstalling the cowling

• Like many composite components the cowling derives its rigidity from being

screwed together. Once you start to remove the screws the cowling becomes

“floppy” and can easily twist and damage surrounding parts

• Take part of an old cardboard box about 18” x 24” and cut a “mouse hole” about

4” in diameter in the center of the lower edge

• Place this piece of cardboard between the back of the prop spinner and the

cowling with the mouse hole sitting over the crankshaft

• Keep this in place for both removal and reinstallation of the cowling

• Also, be aware that there are environmental air ducts that attach to the lower

cowling and these need to be reattached during reinstallation

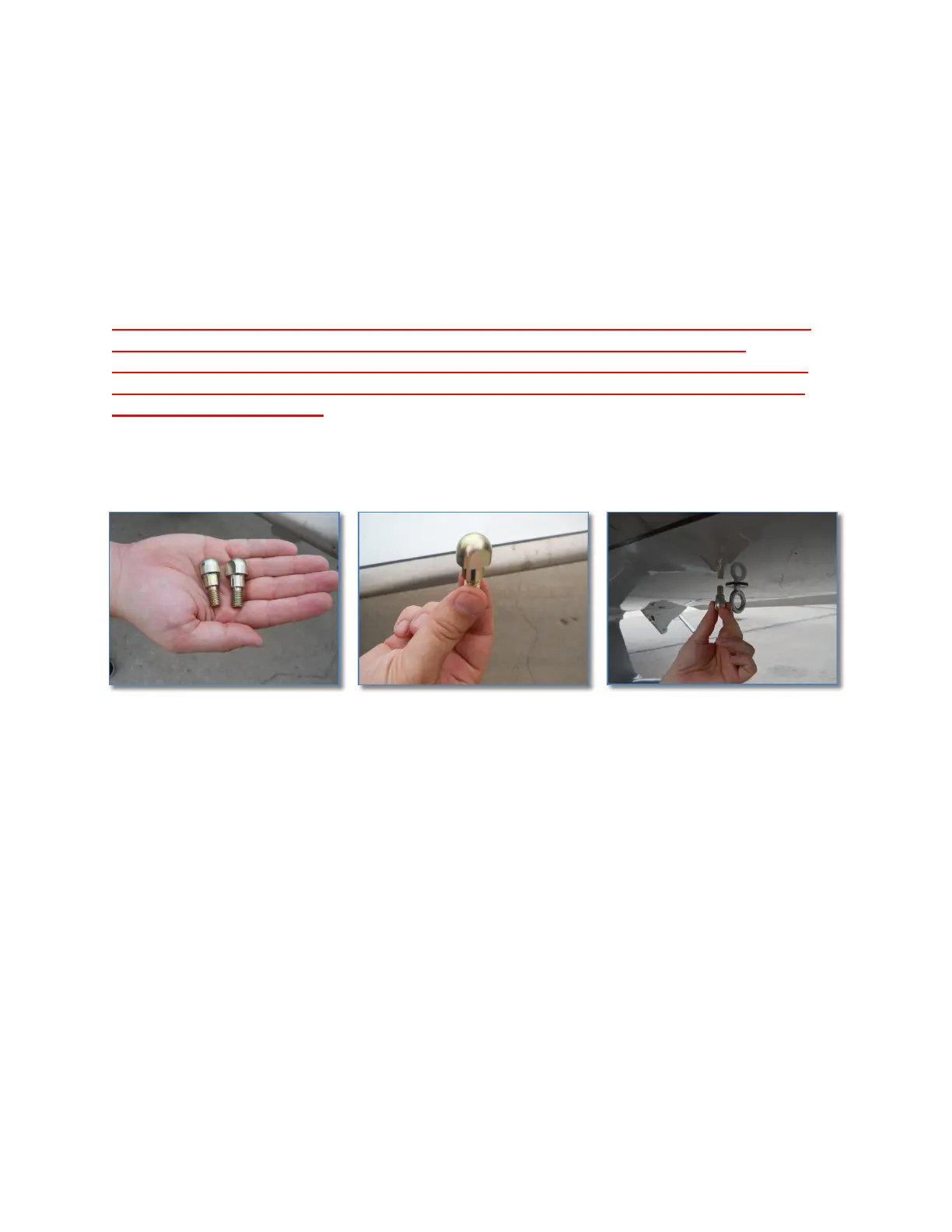

• When re-installing the cowling make 100% sure you have replaced the screws at

the 9 O’clock and 3 O’clock positions in the air intakes just behind the prop

Loading...

Loading...