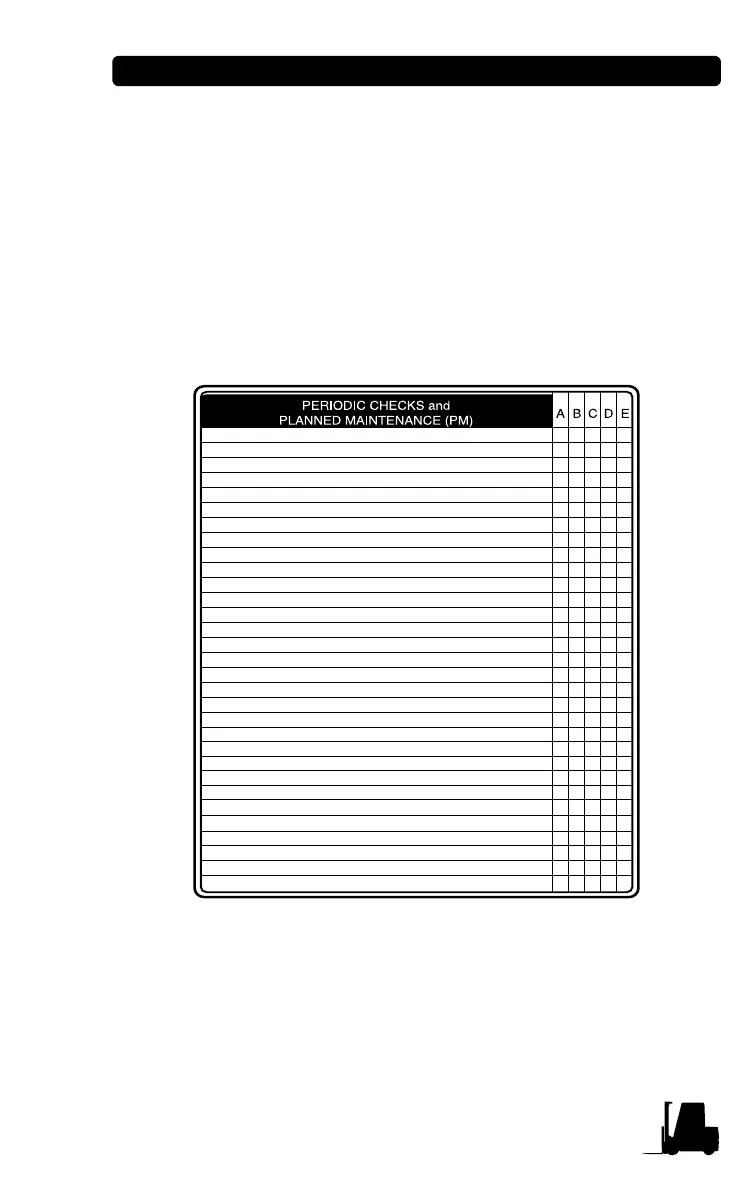

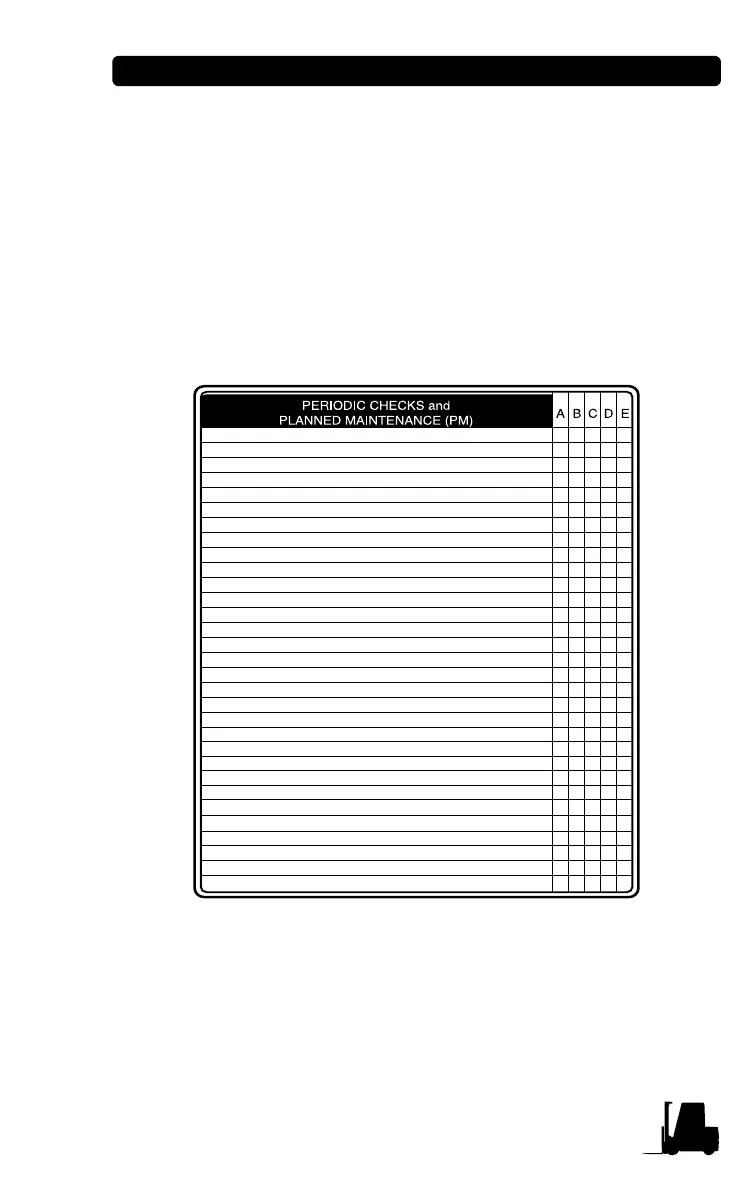

Planned Maintenance Intervals 7-11

Section 7. Planned Maintenance and Lubrication

The maintenance time intervals referred to in this manual relate to

truck operating hours as recorded on the hourmeter, and are based

on experience CLARK has found to be convenient and suitable

under typical (normal or average) operating conditions. The periods

and their designations are:

PM Interval:

A=8 - 10 hours or daily

B=50 - 250 hours or every month (typical PM interval)

C=450 - 500 hours or every 3 months

D=900 - 1000 hours or every 6 months

E=2000 hours or every year

NOTES:

* Air filter change interval may be determined by using an air

restriction indicator.

** Hydraulic filter change interval may be determined by hydraulic

filter restriction indicator.

Check truck visually and inspect components.

Test drive truck/check functional performance.

Air clean truck and radiator.

Check torque on critical fasteners.

Lubricate truck. (See component)

Drain and replace engine oil. (GAS & DSL)

Replace gas engine oil filter.

Replace diesel engine oil filter.

Clean and replace gas engine air filter. (*)

Clean and replace diesel engine air filter. (*)

Change diesel fuel filter

Change gas fuel filter

Inspect / adjust fan belts.

Drain / flush radiator coolant.

Check engine ignition and timing.

Engine tune-up.

Check battery.

Check transaxle fluid level.

Change transaxle fluid. (drain and replace)

Change (replace) transaxle oil filter.

Clean drive axle air vent.

Check brake condition and wear.

Check drive axle mounting and fasteners.

Lubricate steer axle linkage.

Check / lubricate steer axle wheel bearings.

Change / replace hydraulic sump oil filter and breather. (**)

Change / replace hydraulic sump fluid and oil filter. (**)

Lubricate tilt cylinder rod ends.

Check lift chain adjustment and wear.

Check / lubricate lift chains.

Lubricate upright rollers.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Loading...

Loading...