8-14 Lift Truck Maintenance

Uprights and lift chains require special attention to main-

tain them in safe operating condition.

• Uprights can drop suddenly. Look at the upright, but

keep hands out.

• Lift chain repairs and adjustments should be made by

trained service personnel.

Forks

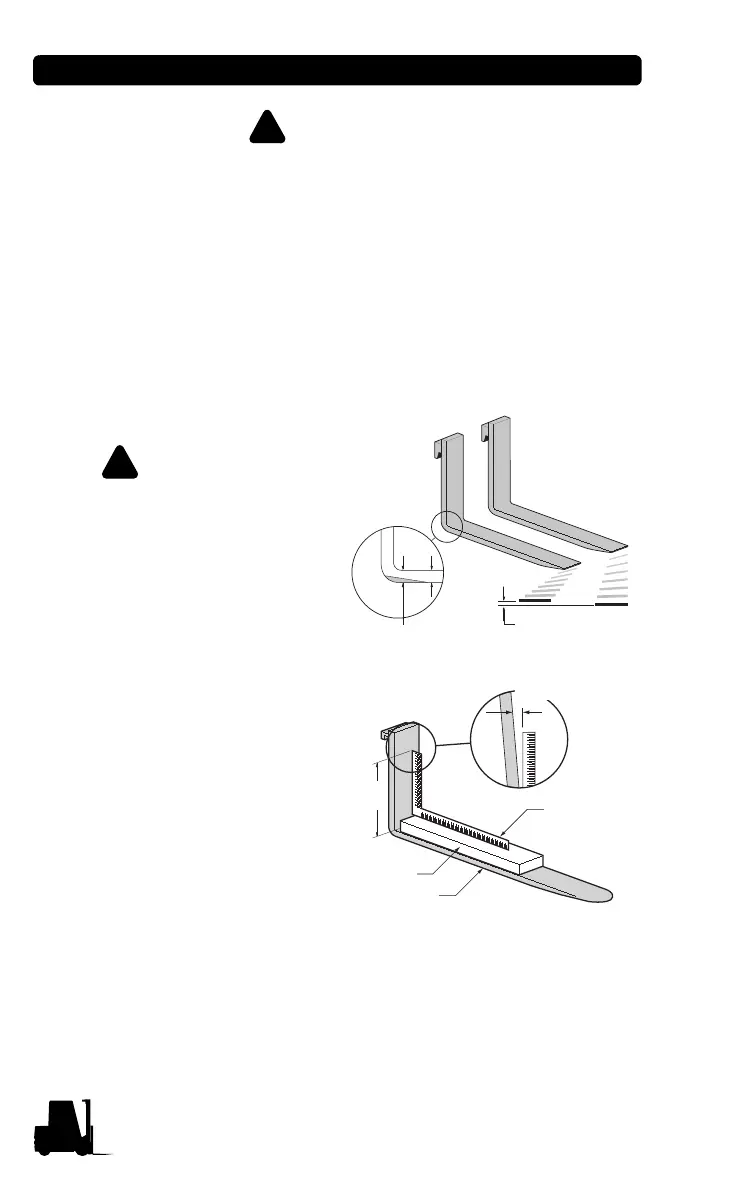

Inspect the load forks for cracks, breaks, bending and wear. The fork

top surfaces should be level and even with each other. The height

difference between both fork tips should be no more than 1.5% of the

blade length.

If the fork blade heel is

worn down by more than

10 percents, the load

capacity is reduced and the

fork must be replaced.

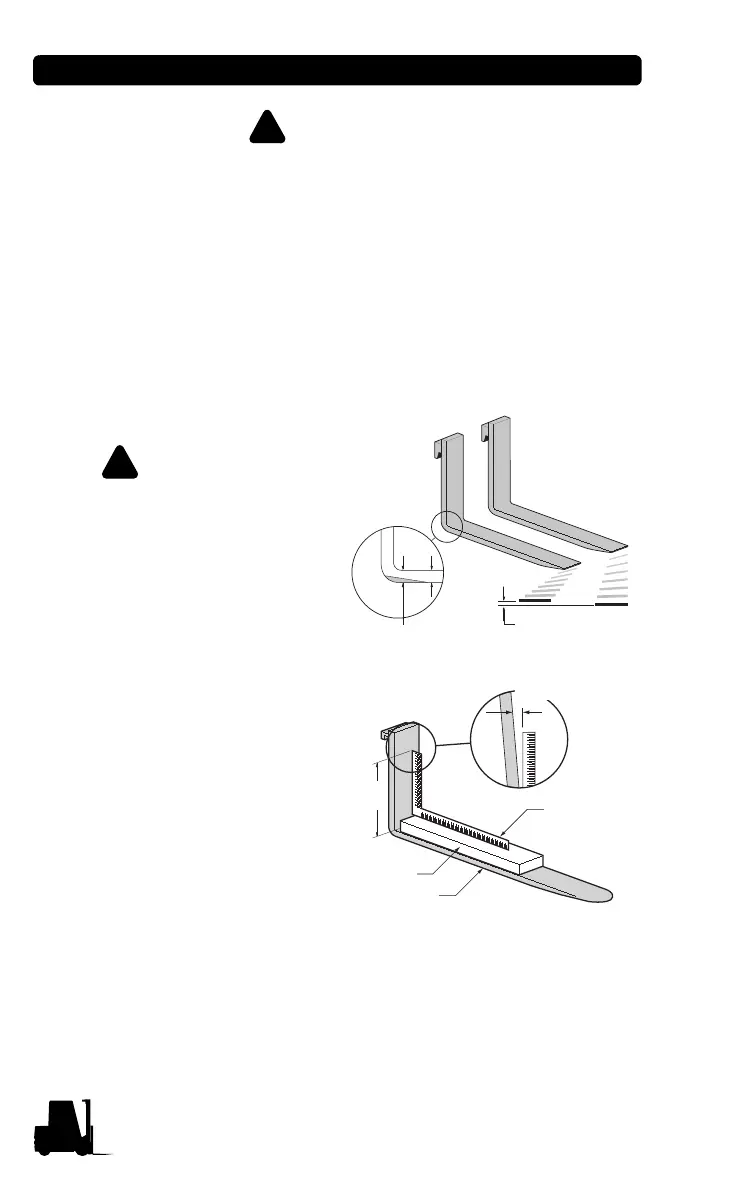

Inspect the forks for twists

and bends. Put a 2" thick

metal block, at least 4" wide

by 24" long, on the blade of

the fork with the 4" surface

against the blade. Put a 24"

carpenter's square on the top

of the block and against the

shank. Check the fork 20"

above the blade to make sure

it is not bent more than 0.6"

(14.5 mm) maximum.

If the fork blades are obviously bent or damaged, have them

inspected by a trained maintenance person before operating the

truck.

Inspect the fork locating pins. Be sure they are not damaged or

broken and operate freely and lock correctly. Check the fork stop

pins for secure condition.

A

10% of "A" is

max. wear

1.5% is

max. height

difference

20"

Carpenter

Square

Blade

2" X 4"

50 cm

(20 in)

5 x 10 cm

(2 x 4 in)

Blade

Carpenter

square

14.5mm(0.6 in)

Loading...

Loading...