3.2.5 Exhaust System

Excessive back pressures to the engine exhaust can

considerably reduce both engine performance and

life. It is therefore important that exhaust systems

should be the proper diameter and be as short as

possible within the minimum amount of bends. Refer

to Installation & Operating (see Page 5) for exhaust

data. Also refer to table below for maximum exhaust

restrictions.

The installation of the exhaust system should consist

of the following:

• Personnel protection from hot surfaces.

• Adequate supports to prevent strain on the

engine exhaust outlet and minimize

vibration.

• Protection against entry of water and other

foreign matter.

While the engine is running inspect exhaust pipe

outlet outside of the pump room itself for

environmental hazards such as excessive smoke

conditions. The following could be used as a guide

for general engine operating conditions.

1) Blue Smoke – Possible engine oil

consumption.

2) White Smoke – Possibility of water in

cylinders, water in fuel or internal engine

problem.

3.3 LUBRICATION SYSTEM

3.3.1 Checking Sump Oil

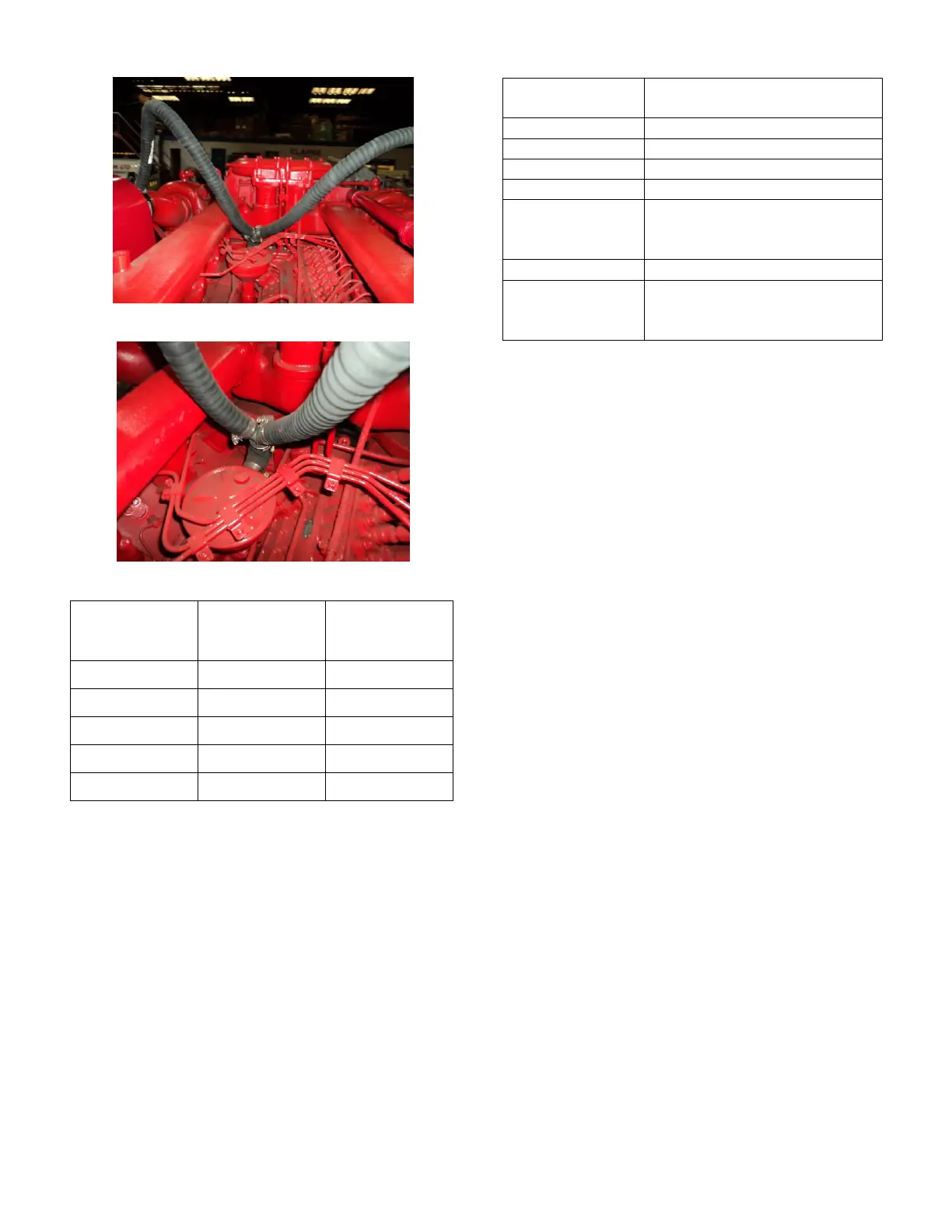

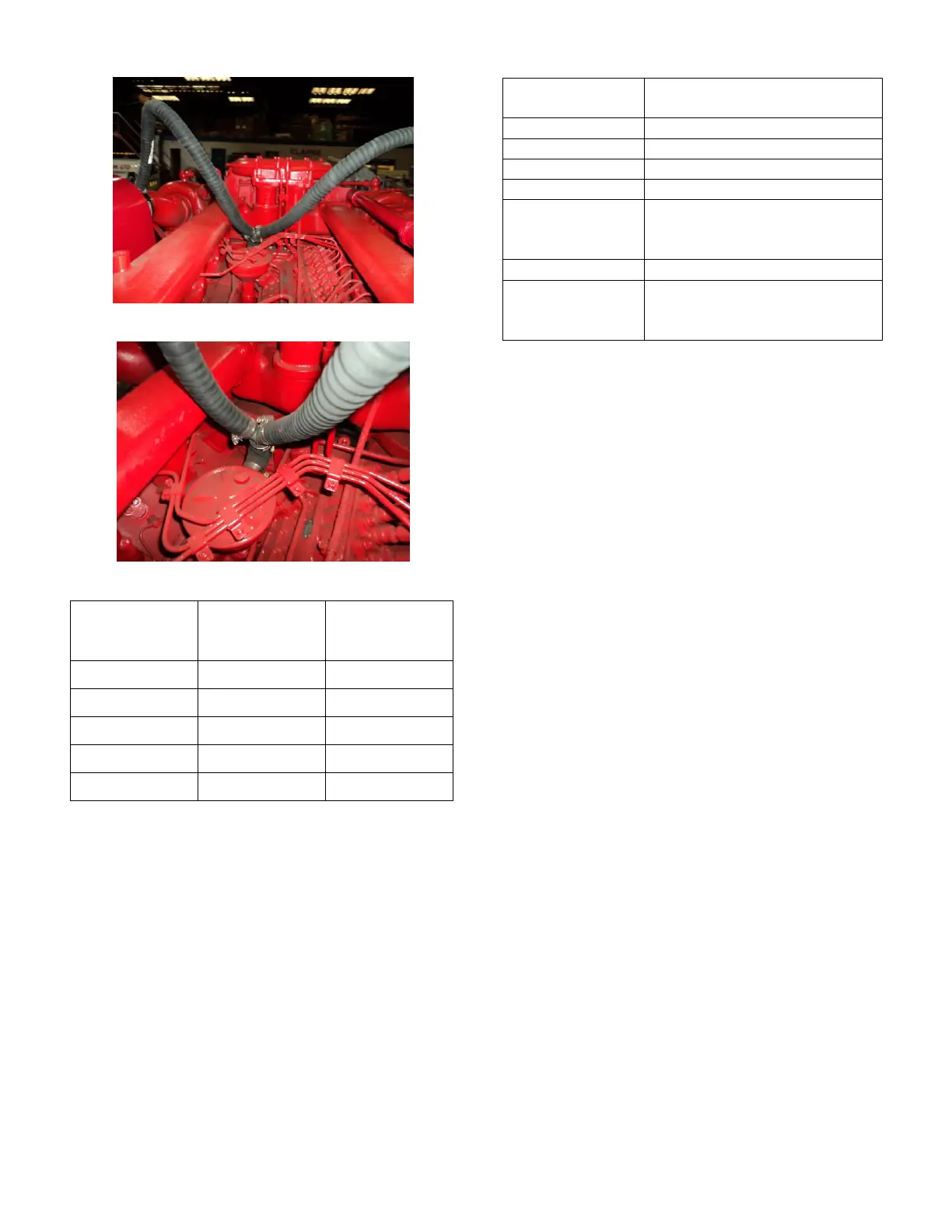

Check the sump oil level using the dipstick on the

engine as shown in Figures #18A and 18B.

This level must always be between the dipstick marks

Min. and Max. with the engine not running. On

DT2H engines the dipstick should be reinserted for

measurement very slowly so that the level on the

dipstick is accurate.

Loading...

Loading...