Page 18 of 49

2.5.2 To Stop Engine

If engine is started from main pump controller use

main pump controller to stop the engine.

If engine is started from engine gauge panel: Return

MODE SELECTOR switch to

AUTOMATIC/MANUAL STOP position, engine

will stop. Close cooling system manual by-pass

valve if opened.

IMPORTANT: DO NOT leave the MODE

SELECTOR switch in the MANUAL RUN position

during AUTOMATIC operation. (The controller

will be unable to stop the engine and DAMAGE

MAY RESULT).

2.5.3 Emergency Stop Instructions

If energized to stop solenoid fails, you will NOT be

able to stop the engine from the instrument control

panel or fire pump controller. Use the emergency

stop lever to choke off fuel supply and shut the

engine down.

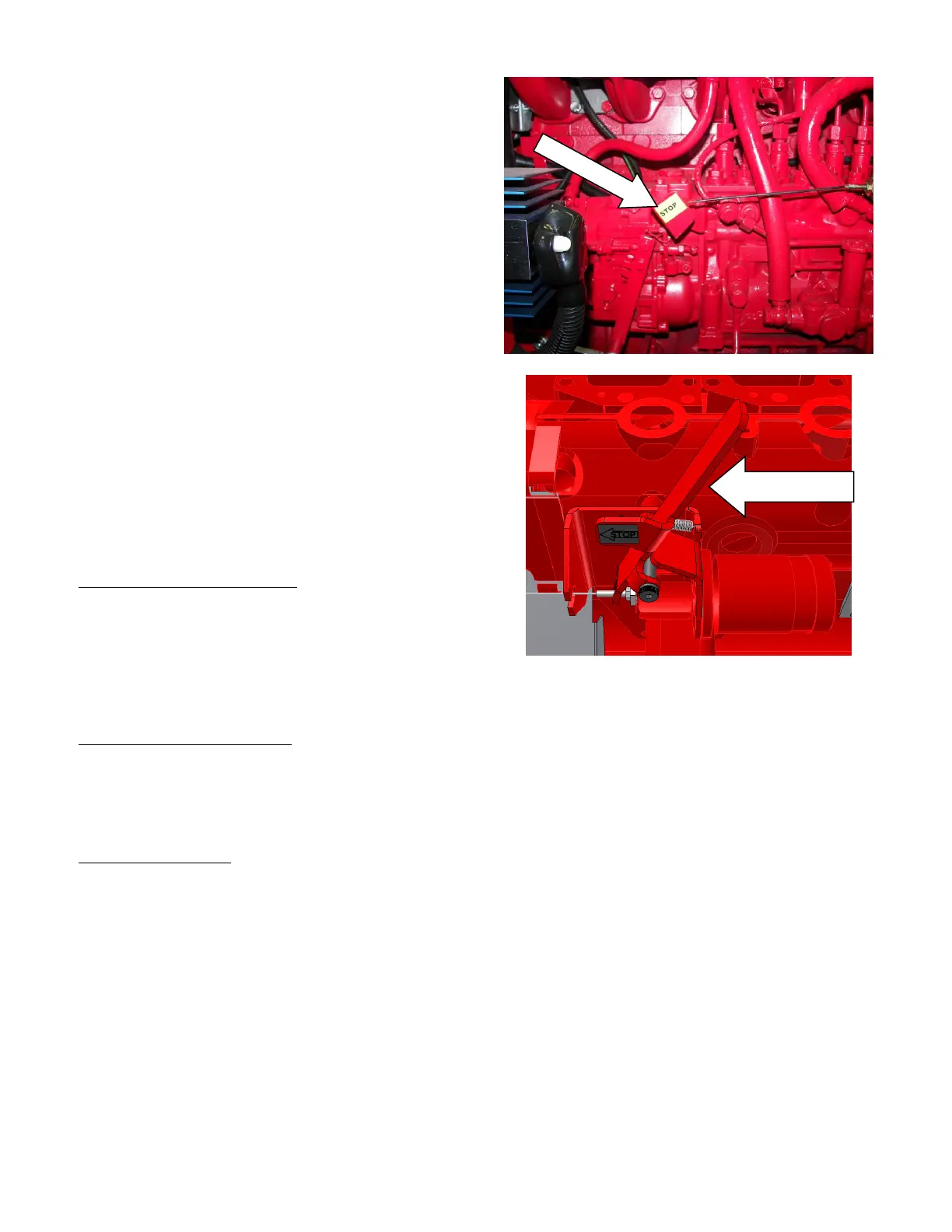

DP6H & DQ6H engine models: The emergency stop

lever is located on the right side (same side as

instrument panel) of the engine on the fuel injection

pump. To stop the engine, rotate the emergency stop

lever clockwise until it stops (see Figure #10A).

Continue to hold lever in “STOP” position until

engine comes to a complete stop.

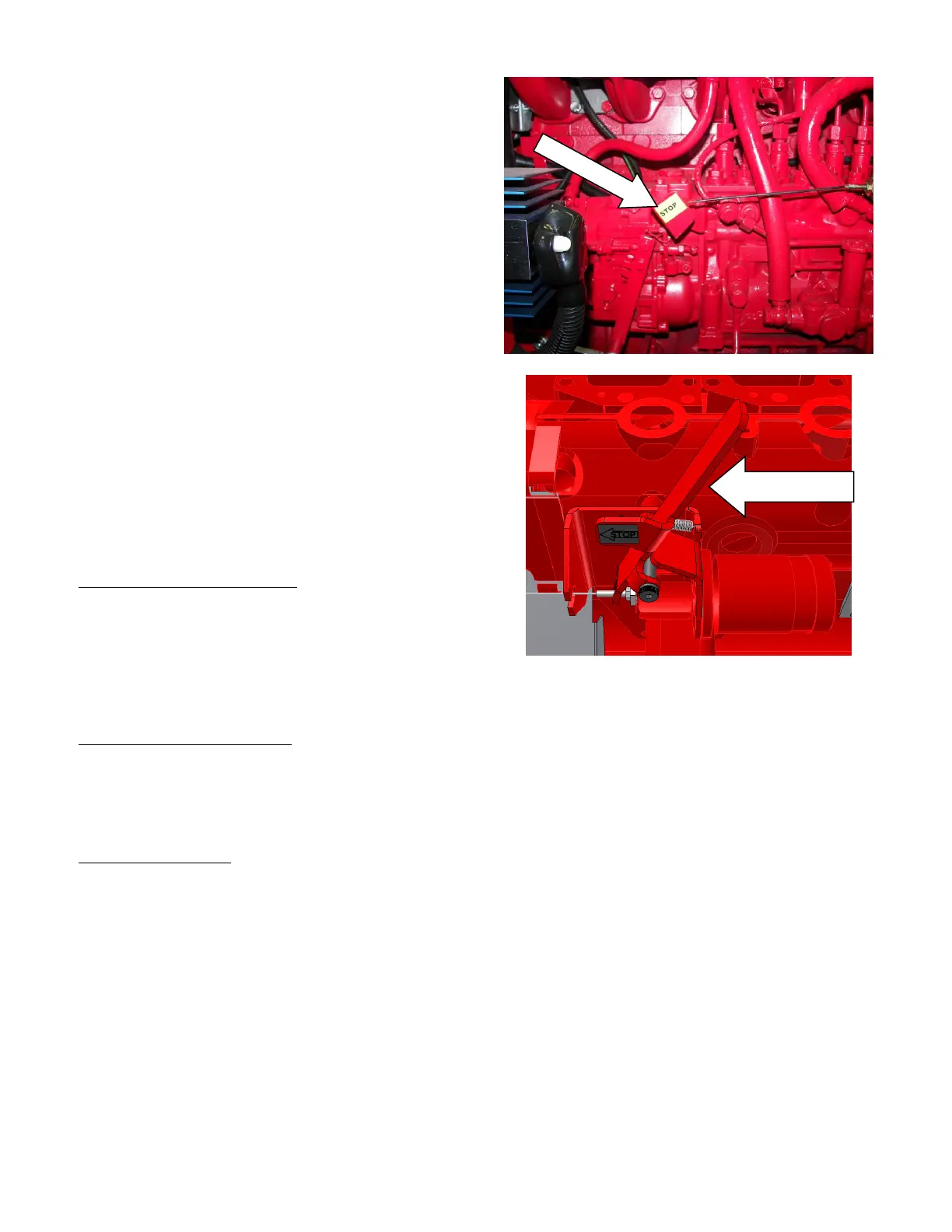

DR8H & DS0H engine models: The emergency stop

lever is located near the front of the engine. To stop

the engine rotate the emergency stop lever until it

stops. Continue to hold lever in “STOP” position

until engine comes to a complete stop.

DT2H engine models: If energized to stop solenoid

fails, you will NOT be able to stop the engine from

the instrument control panel or fire pump controller.

This solenoid is located on the left side (opposite side

of instrument panel) of the engine towards the front.

To stop the engine, rotate the emergency stop lever

counter-clockwise until the solenoid plunger is

completely depressed (see Figure #10B). Continue

to hold lever in “STOP” position until engine comes

to a complete stop.

Figure #10A

Figure #10B

2.6 WEEKLY TEST

An experienced operator should always be present

during the weekly test.

NOTE: This engine is designed to operate at rated

load conditions. For testing purposes the engine can

be run at lower load (lower flow) conditions.

Running times in any one period should not exceed

30 minutes maximum.

Before starting the engine make sure of the

following:

1) The operator has free access to stop the

engine in an emergency.

2) The plant room ventilation ducts are open

and the engine has good access for air.

3) All the guards are in position and, if not, for

whatever reason, any rotating parts will be

free and clear without restriction.

4) Battery covers are in place and there is

nothing on top of or touching the engine,

Loading...

Loading...