INSTRUCTIONS

AND

PARTS

' !

DIVISION, ATLAS

PRESS

COMPANY

KALAMAZOO,

MICHIGAN

49001

...

LEVELING

THE

DRILL

PRESS

Drill

press

should

be

level

and

rest solidly

on

Boor; place

~

shims

underneath

the

three

foundation

holes

to

level

the

drill

press. Equal pressure should

be

applied

to founda-

tion

bolts

to

prevent

distorting

the

base.

1661

RAISING HEAD

AND

TA-

BLE

TO

OPERATING

POSITION

1.

To

position

drill

head, loosen

clamp

handle

on

left

side

of

drill

press.

2.

Slide

head

up

column

to

desired

height

and

tighten

clamp handle.

3. Loosen set screw

in

safety collar

and

slide

it

up

column

until

it

touches

bottom

of

head,

then

tighten

set screws.

4.

To

position table, loosen

clamp

handle

on

right

side

of

table.

5. Slide table

up

column

to

desired

height,

and

tighten

clamp

handle.

Generally, the normal and most convenient position

for the

head is about

8"

to 10" from

top

of

column.

IMPORT

ANT:

Always keep safety collar locked

· · under head.

LUBRICATION

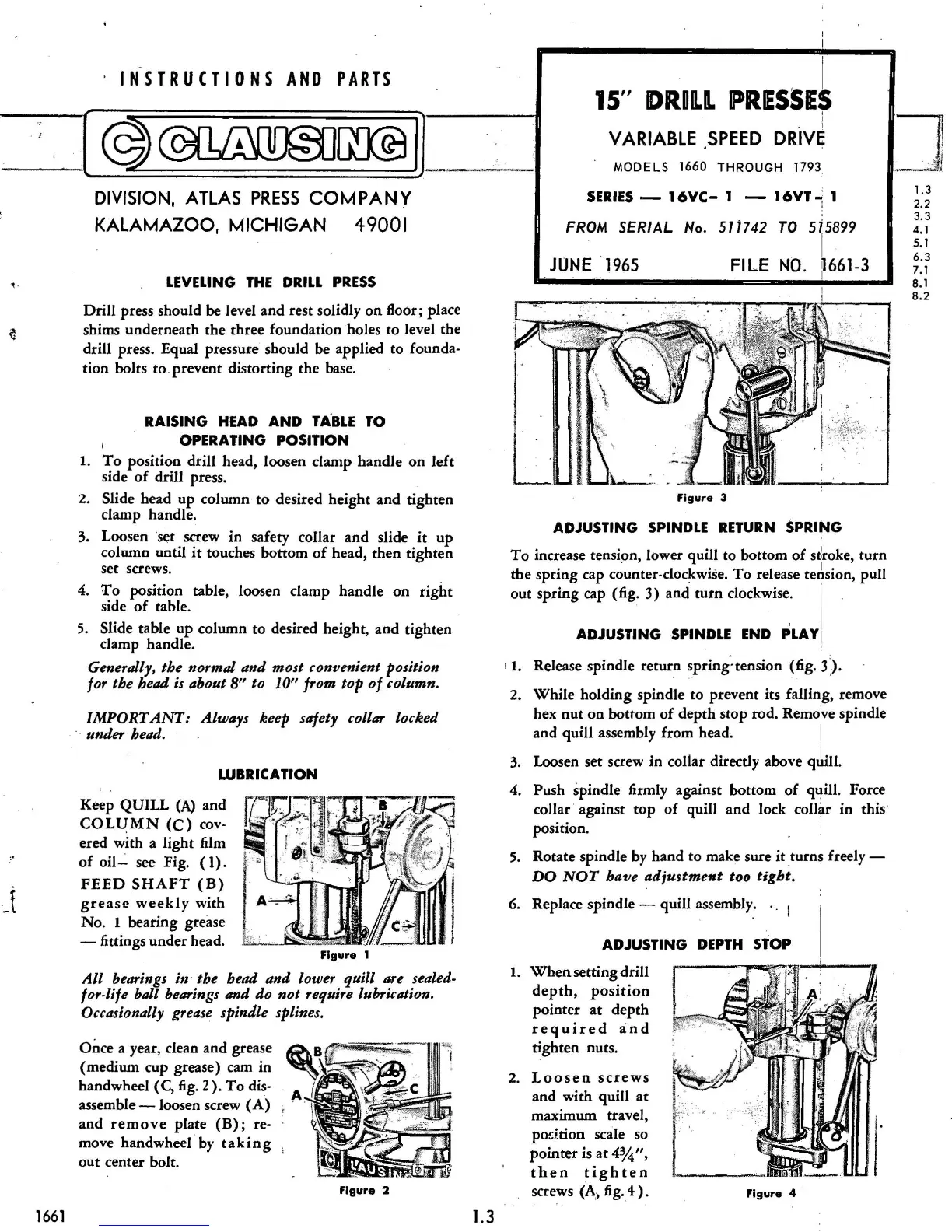

Keep

QUILL

(A)

and

COLUMN

(C)

cov-

ered

with

a

light

film

of

oil_:_

see Fig.

(1).

FEED

SHAFT

(B)

grease

weekly

with

No.

1

bearing

grease

- fittings

under

head.

Figure

1

All

bearings

in

the head and lower quill

Me

sealed-

for-life ball bearings and do not require lubrication.

Occasionally

grease spinJle splines.

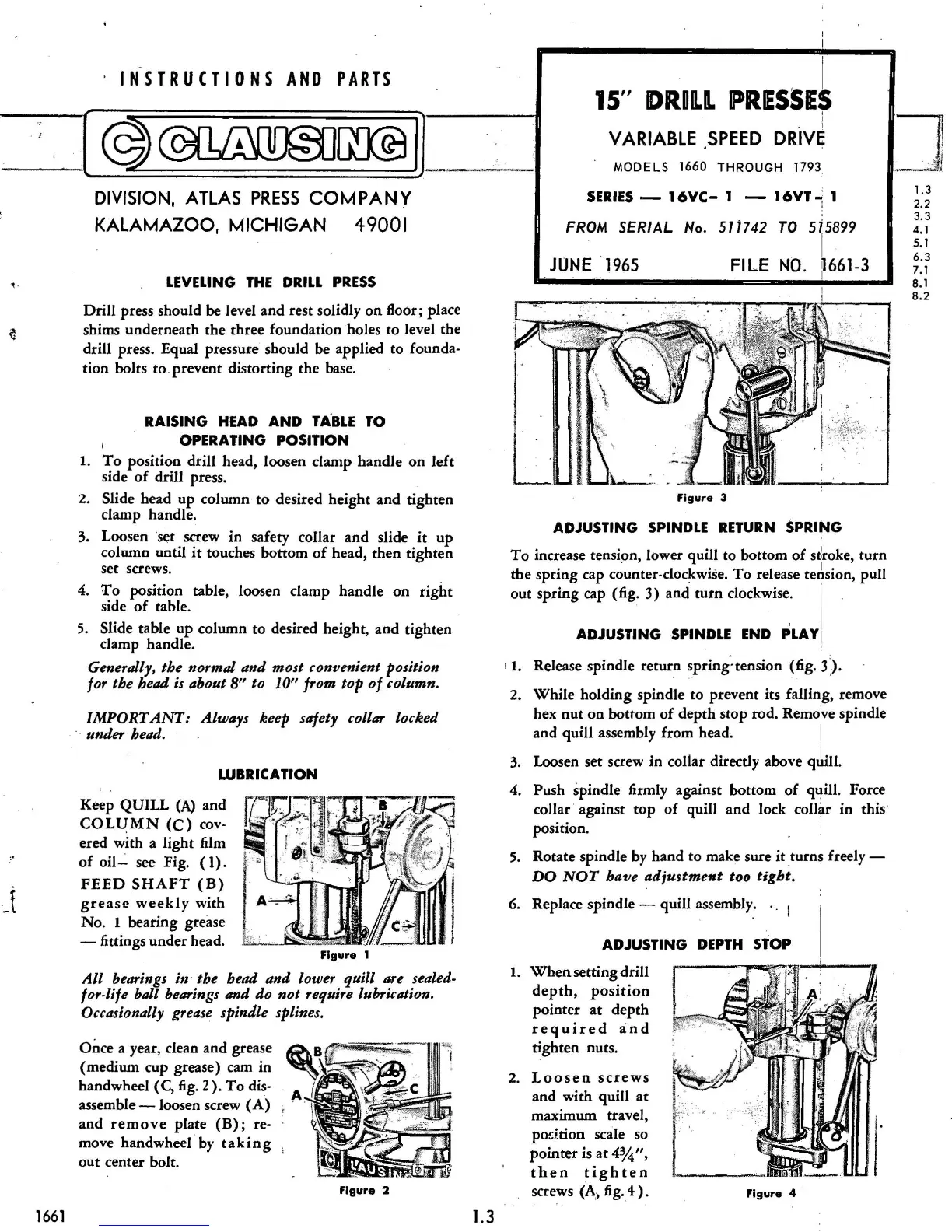

O~ce

a year, clean

and

grease

(medium

cup

grease) cam

in

ha

ndwheel

(C

, fig. 2

).

To

dis-

assemble

-loosen

screw

(A)

,

and

remove

plate

(B);

re

-

move ha

ndwheel

by

taking

out

center bolt.

Figure

2

1.3

. . I

15"

DRDILl

IPRIESSES

I

I

. i

VARIABLE

.SPEED

DRIVE

MODELS

1660 THROUGH 1793

SERIES-

16VC-

1 - 16VT..; 1

;

FROM

SERIAL

No.

511742

TO

5 5899

JUNE

1965

FILE

NO.

Figure

3

ADJUSTING SPINDLE RETURN

SPRING

To

increase tension,

lower

quill

to

bottom

of

s

~

roke,

turn

the

spring

cap

counter

-

doc~wise.

To

release teAsion,

pull

out

spring

cap (fig:

3)

and

turn

clockwise.

ADJUSTING SPINDLE END PLAY[

' 1. Release

spindle

return

S.pring·tension

(fig.

3).

2.

While

holding

spindle

to

prevent

its

falling

, remove

hex

nut

on

bottom

of

depth

stop

rod.

Remo\re

spindle

and

quill

assembly

from

head. j

3. Loosen

set

screw

in

collar directly above qJill.

4. Push

spindle

firmly

against

bottom

of

q4

ill

. Force

collar against

top

of

quill

and

lock

coll~r

in

this

·

position.

5.

Rotate

spindle

by

hand

to

make

sure

it

turns

freely -

DO

NOT

have

adjustment

too

tight.

6. Replace

spindle

-

quill

assembly. . .

1

ADJUSTING DEPTH

STOP

1.

When

setting

drill

depth,

position

pointer

at

depth

r

equired

and

tighten

nuts.

2.

Loosen

screws

and

with

quill

at

maximum

tr

avel,

po

d

tion

scale

so

pointer

is

at

4%",

then

tighten

screws {A, fig.

4)

.

Figure

4 ·

1.3

2.2

3.3

4. 1

5.1

6.3

7.1

8.1

8.2

Loading...

Loading...