Page 38 BB4500-BB5000 Operating Manual

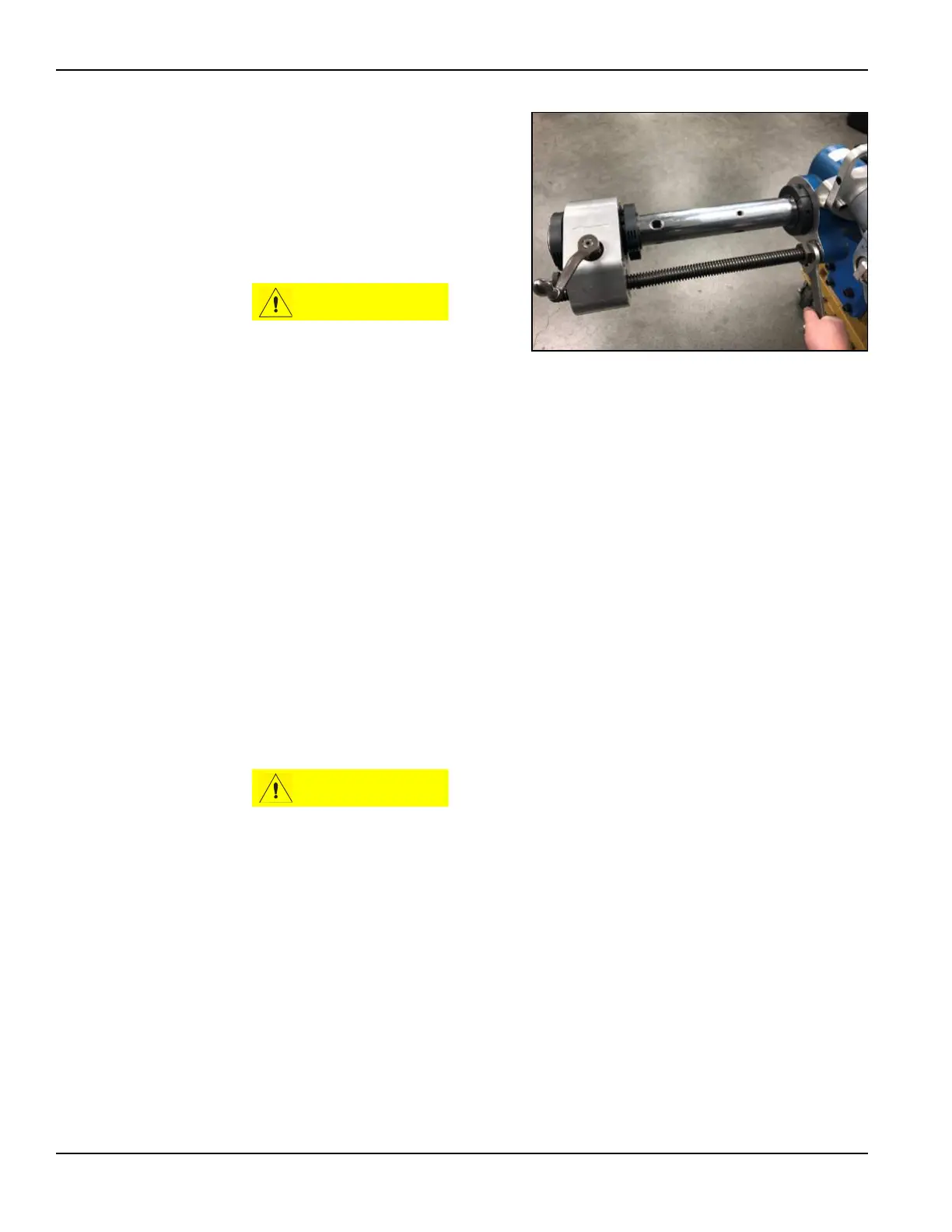

The AFU may be set anywhere

along the bar. It is not necessary to

insert the leadscrew directly into

the RDU. The leadscrew may be

screwed into the tack weld block

that may then be welded or

clamped directly to the workpiece.

Take care not to bend or

unduly stress the leadscrew

during installation.

Do the following:

1. Carefully slide the bar through the spherical mounting bearings.

If positioning the AFU between the mounting support brackets, slide it

onto the bar at this point rather than in step 10.

2. Insert the bar into the opposing bearing bracket.

3. Install the RDU onto the bar, positioning it against the spherical bearing

bracket so that one of the spring pins engages one of the slots in the bearing

mount.

4. Tighten the clamp ring to 30 ft-lbs (41 Nm). Slide the bar to see if it is free

to move. If it does not move, the clamp ring is too tight. Loosen the clamp

ring bolt until the bar has some resistance but moves freely.

The clamp ring must be tightened before the machine is turned on. Do

not rely on the spring pins to hold the rotational torque of the machine.

5. Tighten the clamp collar over the collet, as shown in Figure 3-11 on page

39. Turn the collar screw until the collar is snug, but the bar slides easily

through the unit. In most boring applications, this collar can remain loose.

FIGURE 3-10. POSITIONING THE AFU

Loading...

Loading...