page 5

INSTRUCTIONS FOR THE USER

This is a partial sintex of the information provided in the manual; carefully read this manual

Carefully read this manual. Keep it with the electrical diagram. Make it available to technicians for servicing.

Ask the installer for training on start-up, shutdown, changing set points, placing in at-rest status, maintenance, what to do

or not to do in the event of a breakdown.

Provide for scheduled maintenance by specialized technicians so as to ensure long-lasting operation of the unit.

If you expect the machine to be shut down for long periods of time, disconnect the electrical power supply. In winter, take

necessary measures to deal with possible freezing (unit and system pipes) .

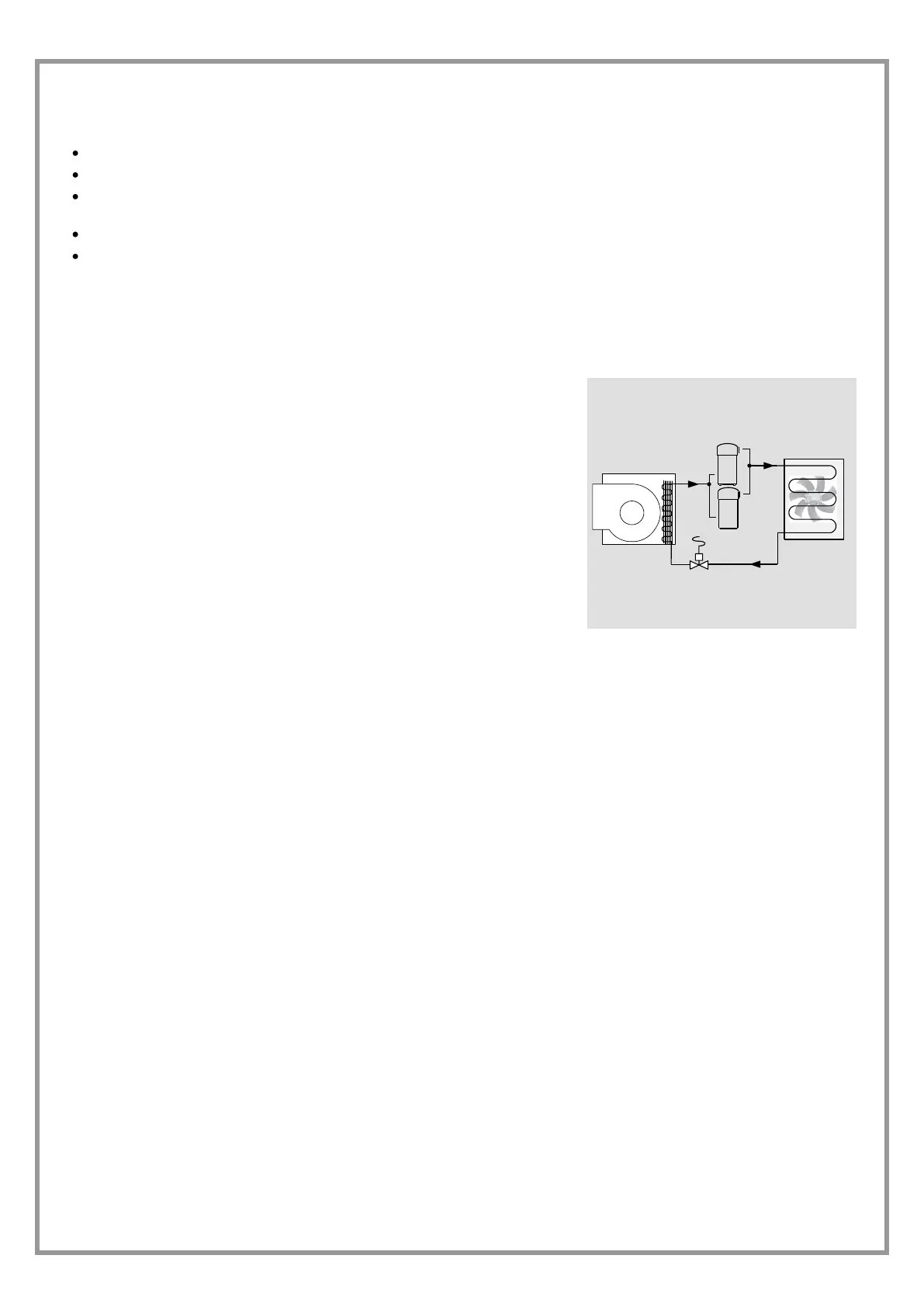

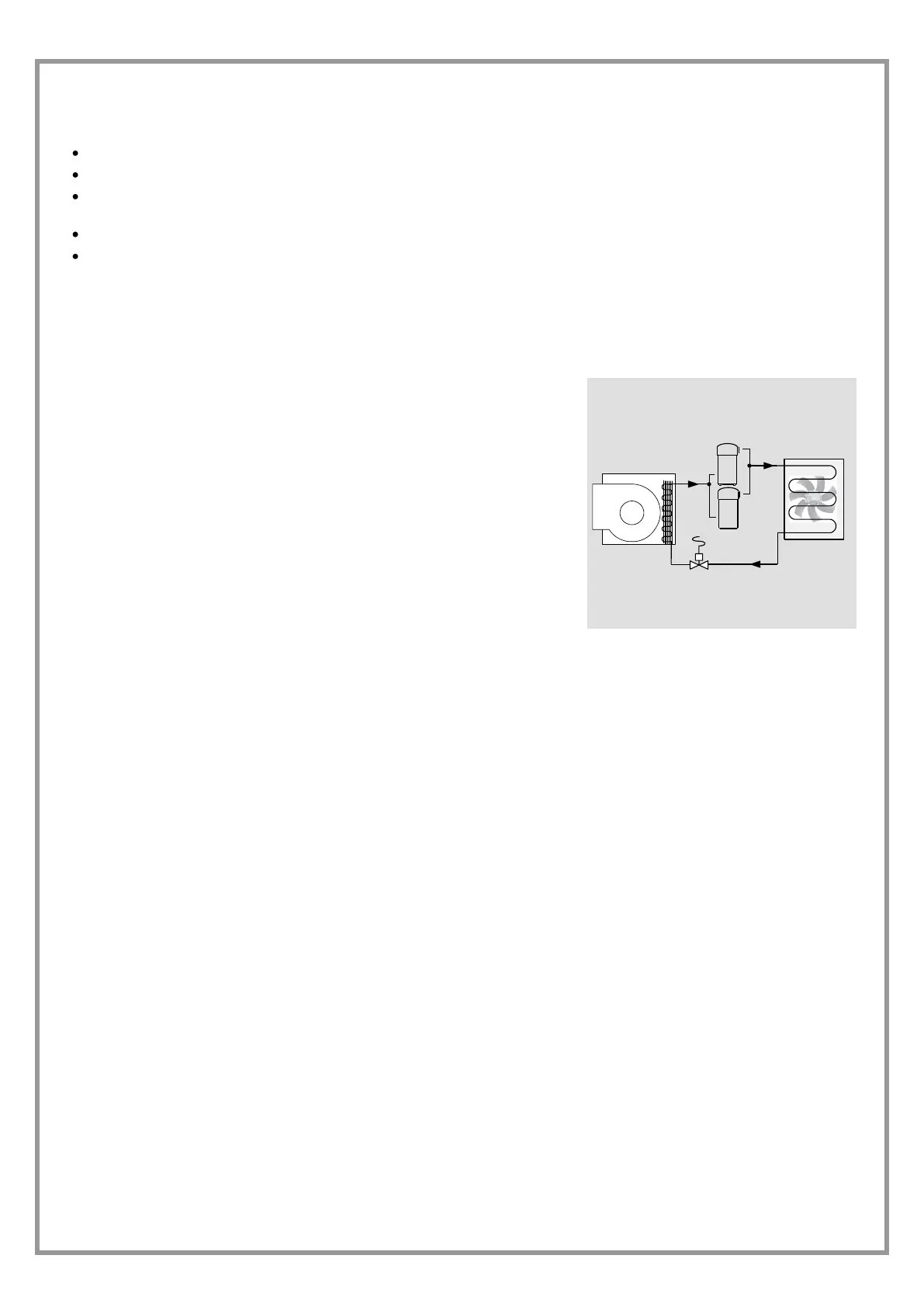

PRINCIPLE OF OPERATION

SUMMER: the cooling cycle allows the transfer of excess indoor heat to the

external environment.

1. The compressor compresses the refrigerant gas, placing it at high pressure

and high temperature.

2. In the external coil, the refrigerant is cooled, and the heat is released to the

outside.

3. When it cools, the refrigerant becomes liquid.

4. The expansion valve causes a sudden drop in the pressure of the refrigerant,

which becomes very cold as its volume increases

5. In the utility side coil, the refrigerant (evaporating) absorbs heat from the

ambient inlet air, cooling it

6. the refrigerant at gaseous status is sucked up by the compressor and the

cycle is repeated

COMMON CAUSES OF SHUTDOWN

air filter dirty

coils dirty - clogged by leaves - nearby obstacles - covered with snow

set point too low (in summer) or too high (in winter)

external permissions (remote ON-OFF etc.)

Loading...

Loading...