23

Starting up the system

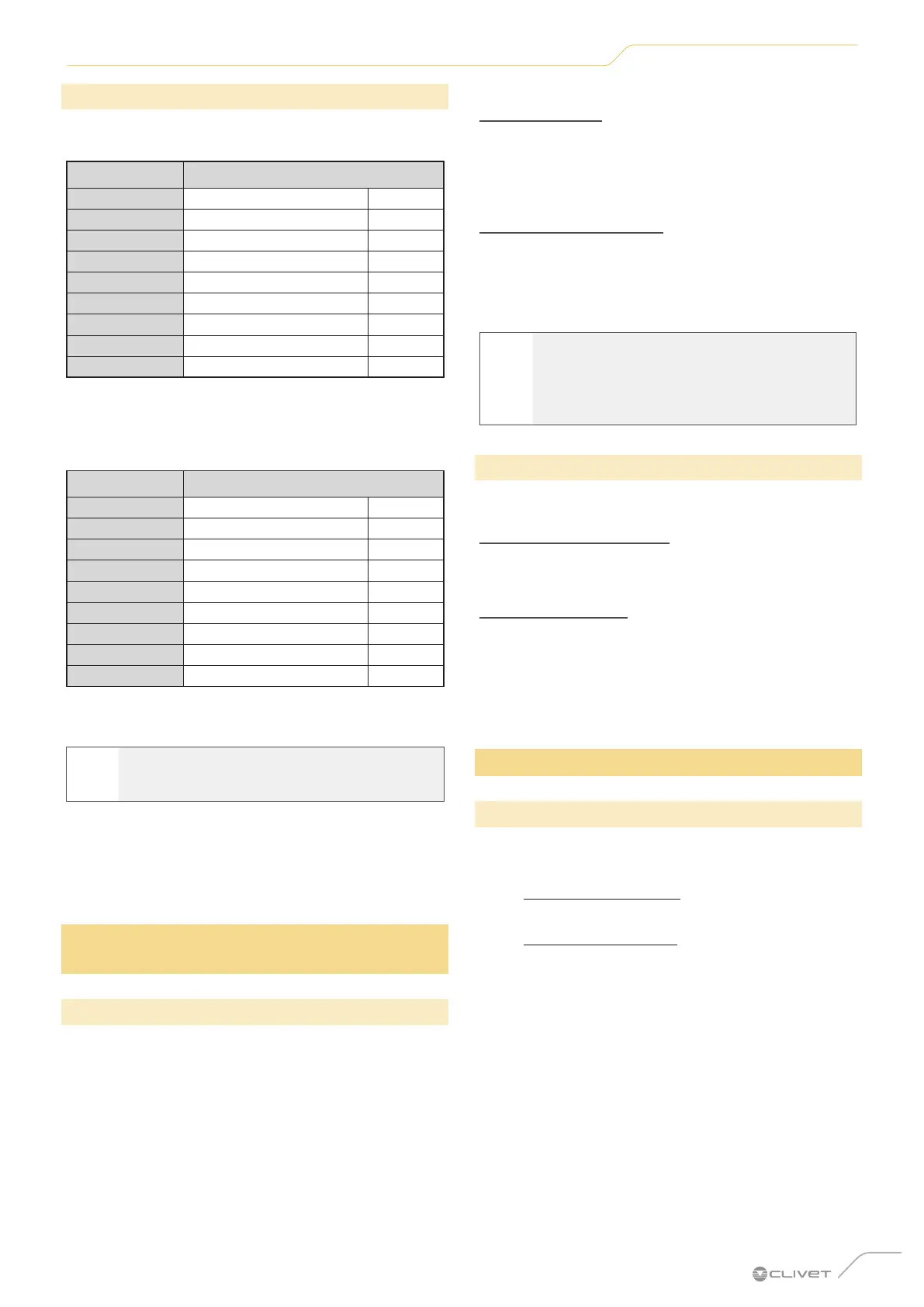

3.1.1 Refrigerant charge

The unit is factory pre-charged with a sufficient quantity

of refrigerant for pipe length up to 5 metres.

Outdoor unit Refrigerant pre-charge

35M 0.87 kg

53M 1.15 kg

70M 1.15 kg

88M 2.0 kg

105M 2.4 kg

105T 2.4 kg

120M 2.8 kg

140T 2.8 kg

160T 2.95 kg

If the length of the pipes is longer than 5 metres, an

additional charge of refrigerant is required.

For each additional metre, the following quantity of

refrigerant must be added:

Outdoor unit Additional charge

35M 12 g/m

53M 12 g/m

70M 24 g/m

88M 24 g/m

105M 24 g/m

105T 24 g/m

120M 24 g/m

140T 24 g/m

160T 24 g/m

The refrigerant must be charged through the low pressure

valve of the outdoor unit.

d

IT IS PROHIBITED TO

mix different types of refrigerant

FULL REFRIGERANT RECHARGE

If a full charge of refrigerant is required (e.g. after moving/

replacing the unit or after a leak), the total refrigerant

charge will be the sum of the factory refrigerant pre-charge

+ the additional charge for pipes longer than 5 metres.

3.2 Electrical dispersion and gas leakage

control

3.2.1 Electrical safety controls

After installation, check that:

– all electrical cables are installed according to

national and local codes and according to the

instructions in the Installation Manual.

– the earth wires are connected properly.

– the system’s electrical voltage is correct for the air

conditioner.

BEFORE THE OPERATING TEST

Checking earthing

Measure the earthing resistance with visual detection

and a specific tester. The earthing resistance must be

less than 0.1Ω.

DURING THE OPERATING TEST

Electrical dispersion control

During the operating test, use an electrode and multimeter

to conduct a complete electrical leakage test.

If an electrical leakage is detected, turn the unit off

immediately and consult a qualified electrician to identify

and resolve the cause of the problem.

f

ATTENTION ELECTRIC DANGER

All electrical connections must be done by a

licensed electrician according to the provisions

of national and local electrical codes.

3.2.2 Checking for gas leaks

There are two different methods of checking gas leaks.

Method with soap and water

Using a soft brush, apply soapy water or liquid detergent to

all pipe joints of the indoor and outdoor units. The bubble

formation will indicate a leak.

Leak detector method

If using a leak detector, follow the instructions in the user

manual of the device.

AFTER CHECKING FOR GAS LEAKS

After checking that the pipe joints are NOT leaking,

re-apply the valve assembly cover to the outdoor unit.

3.3 Operating test

3.3.1 Preliminary checks

The operating test shall be carried out only after the

following procedures have been completed:

– Electrical safety checks - Check that the electrical

system is safe and functioning properly

– Check for gas leaks - Check all joints with

countersunk nuts and check the system for leaks

– Check that the valves on the gas and liquid side

(high and low pressure) are fully open

Also check that:

– there are no obstacles near the unit’s inlet/outlet

that can limit performance or cause the product to

malfunction.

– the drain system is not blocked and the water

flows into a safe place.

– the heat insulation is installed properly.

– the length of the pipes and the amount of

refrigerant added have been recorded.

Loading...

Loading...