20 • Important: Always read and follow operating instructions.

Infl ation

NEVER exceed tire manufacturer's recom-

mended air pressure. Tires can explode,

especially if inflated beyond these limits.

Use clip-on air chuck, keep hands, arms

and entire body back from inflating tire.

Avoid distraction during inflation. Check

tire pressure frequently to avoid over infla-

tion. Excessive pressure can cause tires to

explode, causing serious injury or death to

operator or bystander.

If you change tires defined as truck tires,

they must be inflated per OSHA instructions.

1. Ensure both beads are seated. When both beads

are seated, the tire is ready for inflation.

2. Replace the valve core if it was removed.

3. Depress the inflation pedal to position 2 to inflate

the tire. The pressure limiter will cycle the air flow as

described earlier. On most tires, the pressure limiter

will cease air flow at approximately 60 PSI. On smaller

volume tires the pressure may be higher.

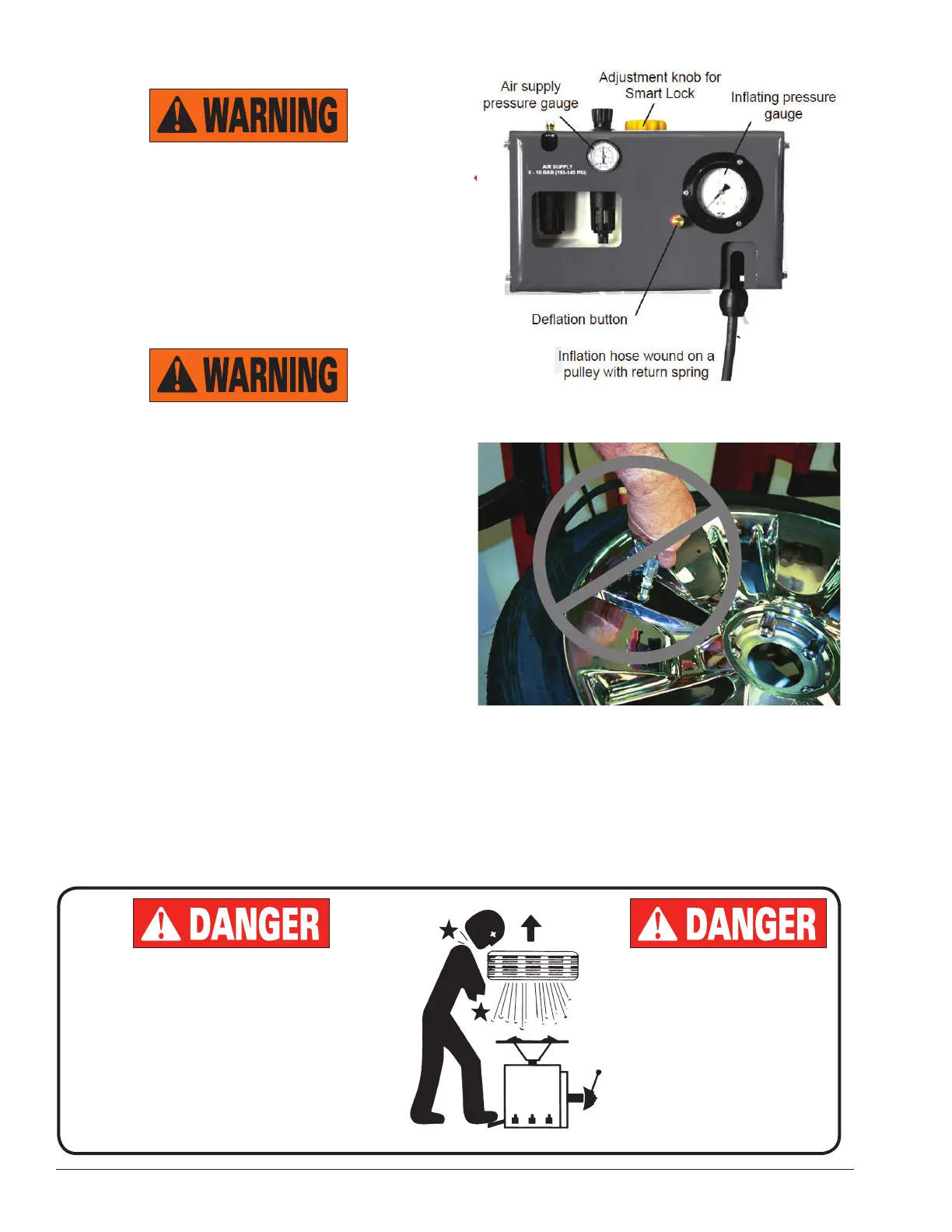

4. Release air pressure from tire by pressing the

manual deflation button (fig. 27). Inflation hose must

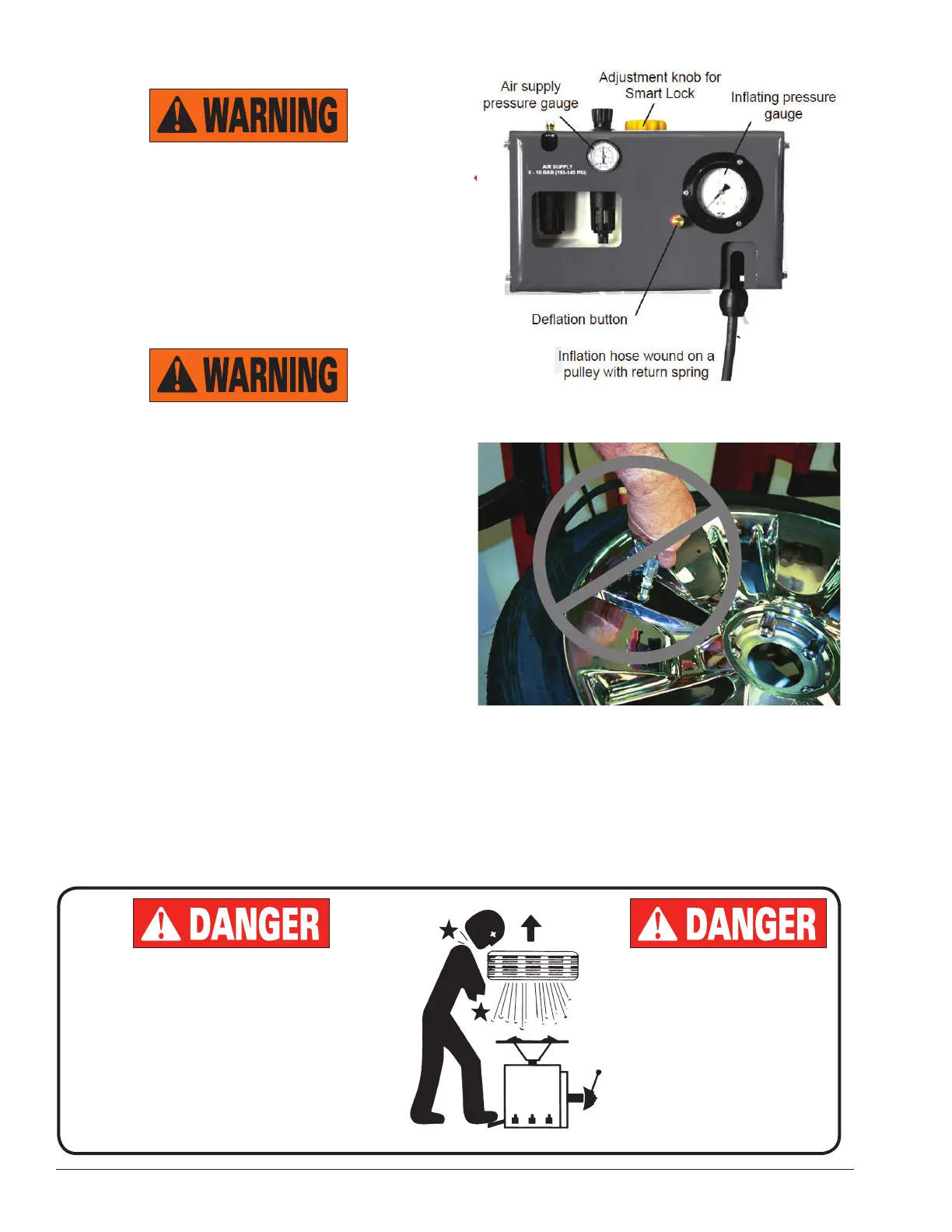

be attached to the valve stem. Never add or adjust tire

pressure using an air hose without a clip-on air chuck

and in-line valve. Do not use a hand-held style chuck

(figure 28).

5. Important: When inflating tires that require more

than 60 PSI, always use a safety cage and air hose with

a clip-on air chuck and in-line valve. The air hose must

have enough length between the chuck and the opera-

tion/in-line valve to allow the operator to stand outside

the trajectory.

Figure 27 - Location of Deflation Button

Figure 28 - Do Not Use a Hand-held Style Air Chuck

Manual Release Valve

Explosion Hazard

Never exceed 40 PSI while

seating beads. If you use

more than 40 PSI always

use safety cage.

Remember R.I.M.

(see page iv and back cover)

Explosion Hazard

Never infl ate tire

above

manufacturer’s

recommended

pressure after

bead is seated.

Loading...

Loading...