- 37 -

6. CLEANOUT, DISASSEMBLING AND REASSEMBLING

OF PARTS IN CONTACT WITH THE PRODUCT

IMPORTANT:

Cleanout and sanitization are important operations that must be carried out at the end of

every working day with utmost accuracy, as a rule, in order to guarantee a high quality

product and the observance of all hygienic rules.

6.1 PRELIMINARY CLEANOUT

To clean the machine do as follows:

l With the machine OFF, opening shut-off valve on machine front side.

l Fill both cylinders with water using the special hose.

l After filling with water, press the button for heating side and the button for

production side.

When programmed time has elapsed, the machine will automatically set at STOP position.

l By first turning the lever 502 and then lowering the handle 5, let all water come out of the cylinders.

l After emptying the freezing cylinder, (front lid is opened by lifting the lever 289 and pulling

it to the right), it is advisable to clean the cylinder with a bolt of water while keeping the

beater blocked in its seat.

l Disassemble then the machine by removing its parts.

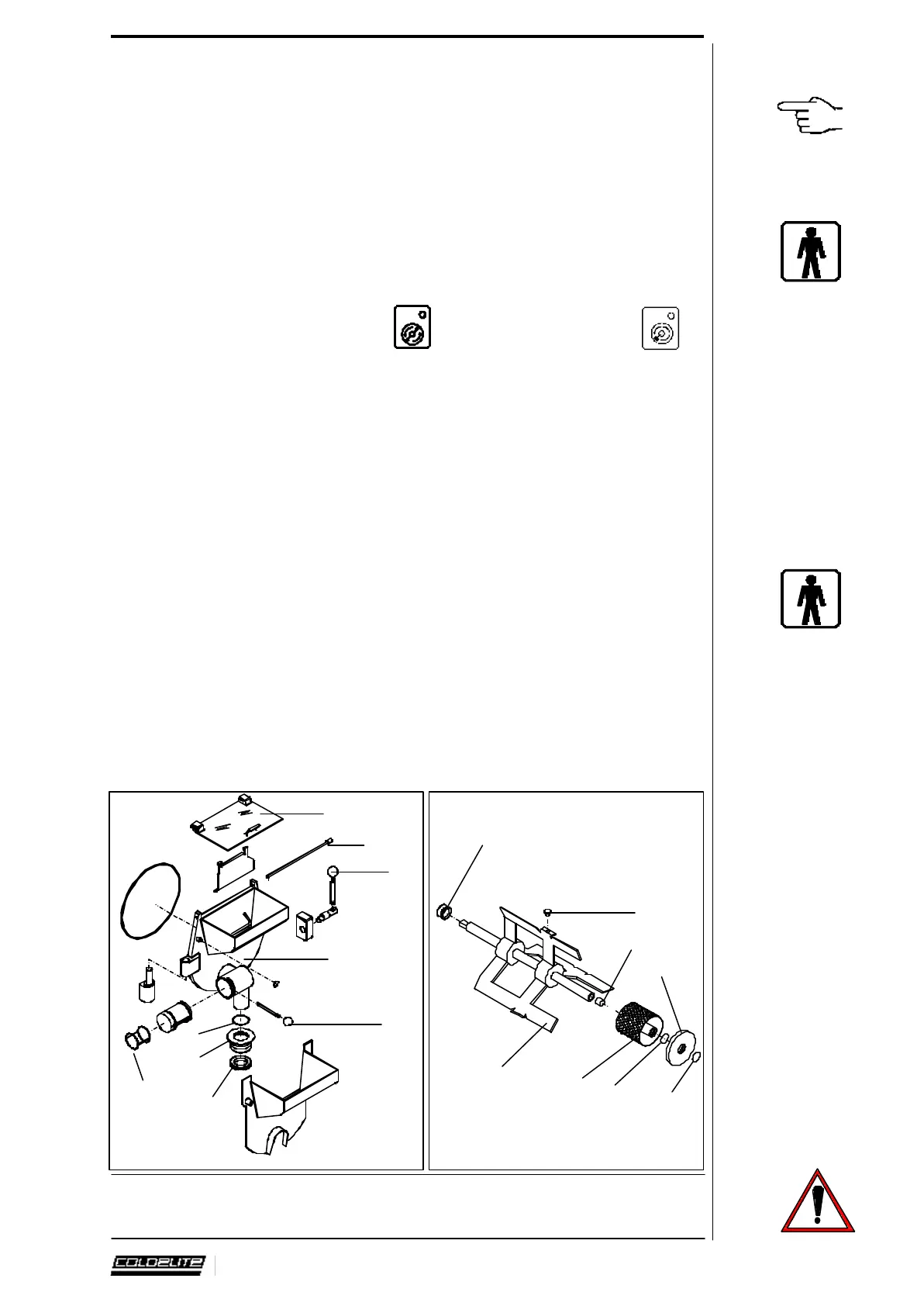

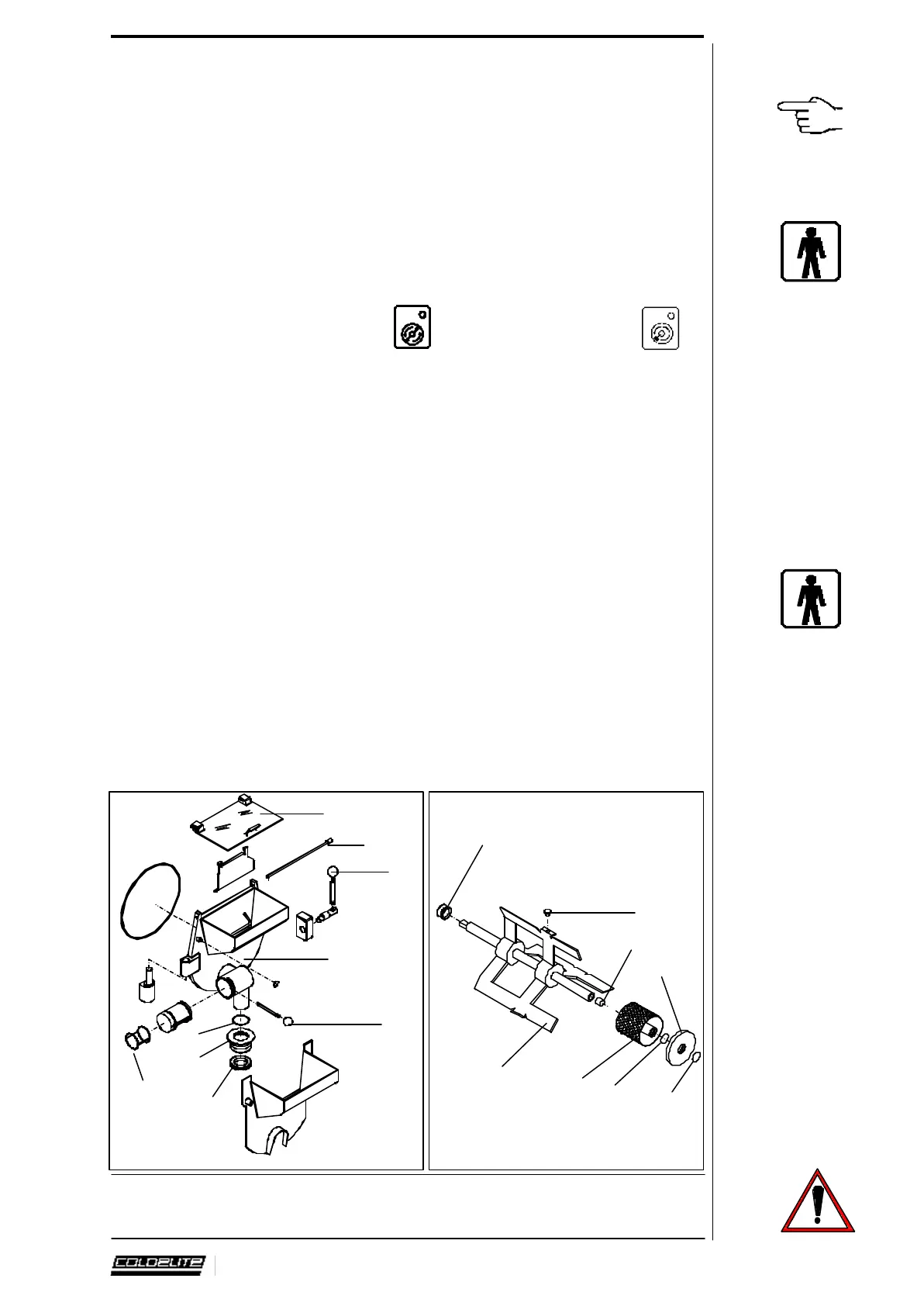

6.2 TOP FRONT LID DISASSEMBLY (HEATING/MIXING

SIDE)

To disassemble front lid 301 release it by lifting lever 289 and shifting it to the right.

l Open the front lid by shifting it to the left and lift it while extracting it from the spigot pin.

l Disassemble the spigot by unscrewing pin 5 and pushing it out of its seat.

l By means of the special extractor, remove seal 303.

l Disassemble front lid mouthpiece protection 290 by extracting check pin 6.

l Disassemble beater 21 after extracting it from its seat, withdraw stuffing box 28 wash them

and, if dirty, also remove plastic plugs 85.

l Withdraw the flavour-case 547, OR 1131 and 1136, cover 547A.

CAUTION!

Clean with sanitizers at the end of every working day.

Handle with care, as a fall to the ground might damage the beater.

303

289

6

290

5

301

304

305

306

28

21

85

85A

547

1131

547A

1136

Loading...

Loading...