b) To enter PID parameter setting mode press (SET), then enter code “0036”, press (SET) again.

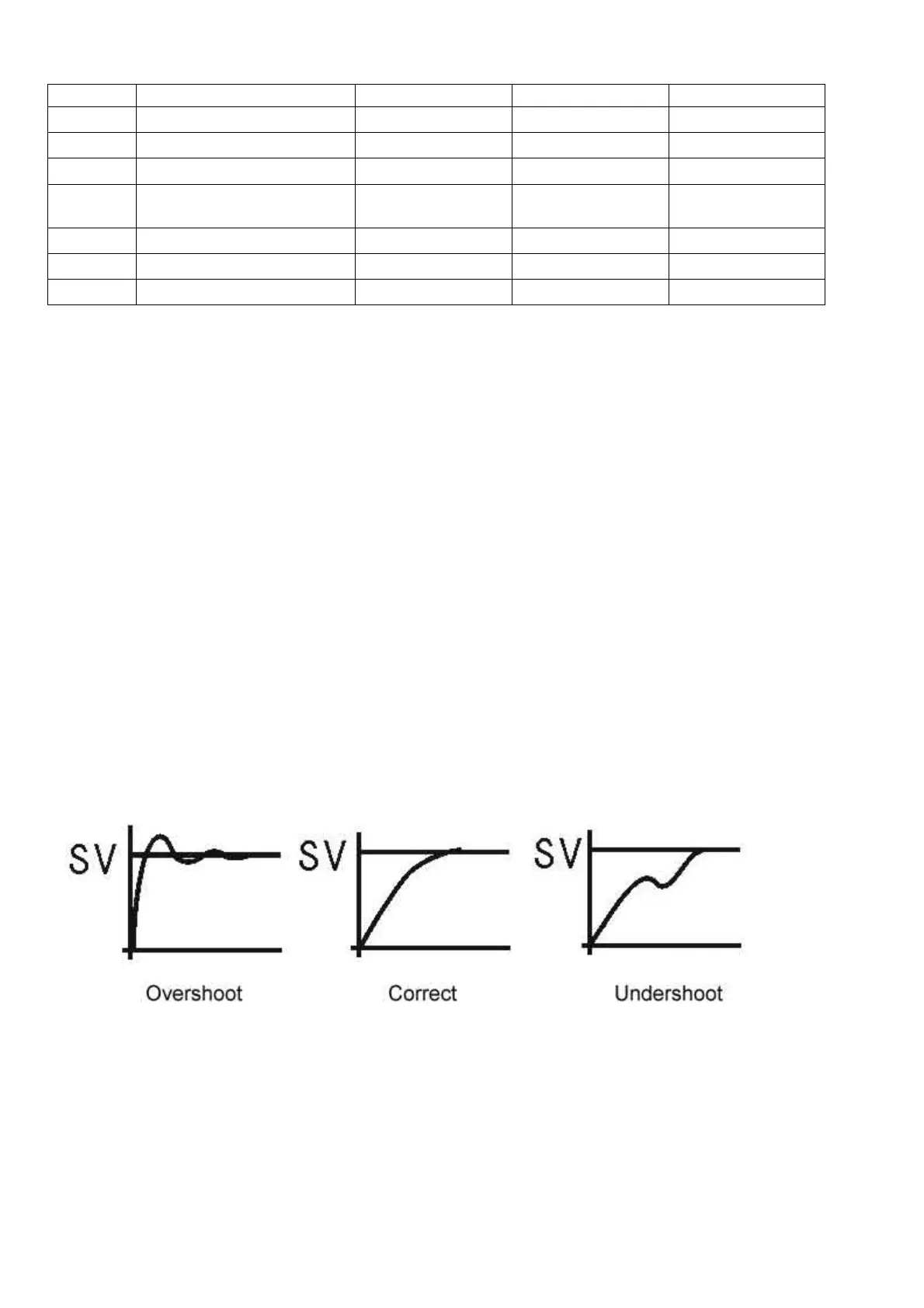

Table 3. PID and Relevant Parameters:

Symbol Description Range Default Comment

P

Proportional Band 0.1 ~ 99.9 (%) 5.0 Note 4

I

Integration Time 2 ~ 1999 (Sec) 100 Note 5

D

Differentiation Time 0 ~ 399 (Sec) 20 Note 6

SouF

Overshoot Suppression

Coefficient

0.0 ~ 1.0 0.2 Note 7

Ot

Control Period 2 ~ 199 (Sec) 2 Note 8

Filt

Digital Filtering Strength 0 ~ 3 0 Note 9

End

Exit

P,I and d parameters control the accuracy and respond time of the temperature controller. Auto-

tuning is recommended for user who does not familiar PID control theory. P, I and d values

should only be adjusted by professionals.

Note 4

Proportional Band (P): When P increases, fluctuation of object being controlled decreases. When

P decreases, fluctuation of object being controlled increases. When P value is too small, system

may become non-converge.

Note 5

Integration time (I): its purpose is to reduce static error. When I decrease, respond speed is

faster but system is less stable. When I increase, respond speed is slower, but system is more

stable.

Note 6

Differentiation time (d): its purpose is to control in advance and compensate delay. Setting d-

value too small or too large would decrease system stability, oscillation or even non-converge.

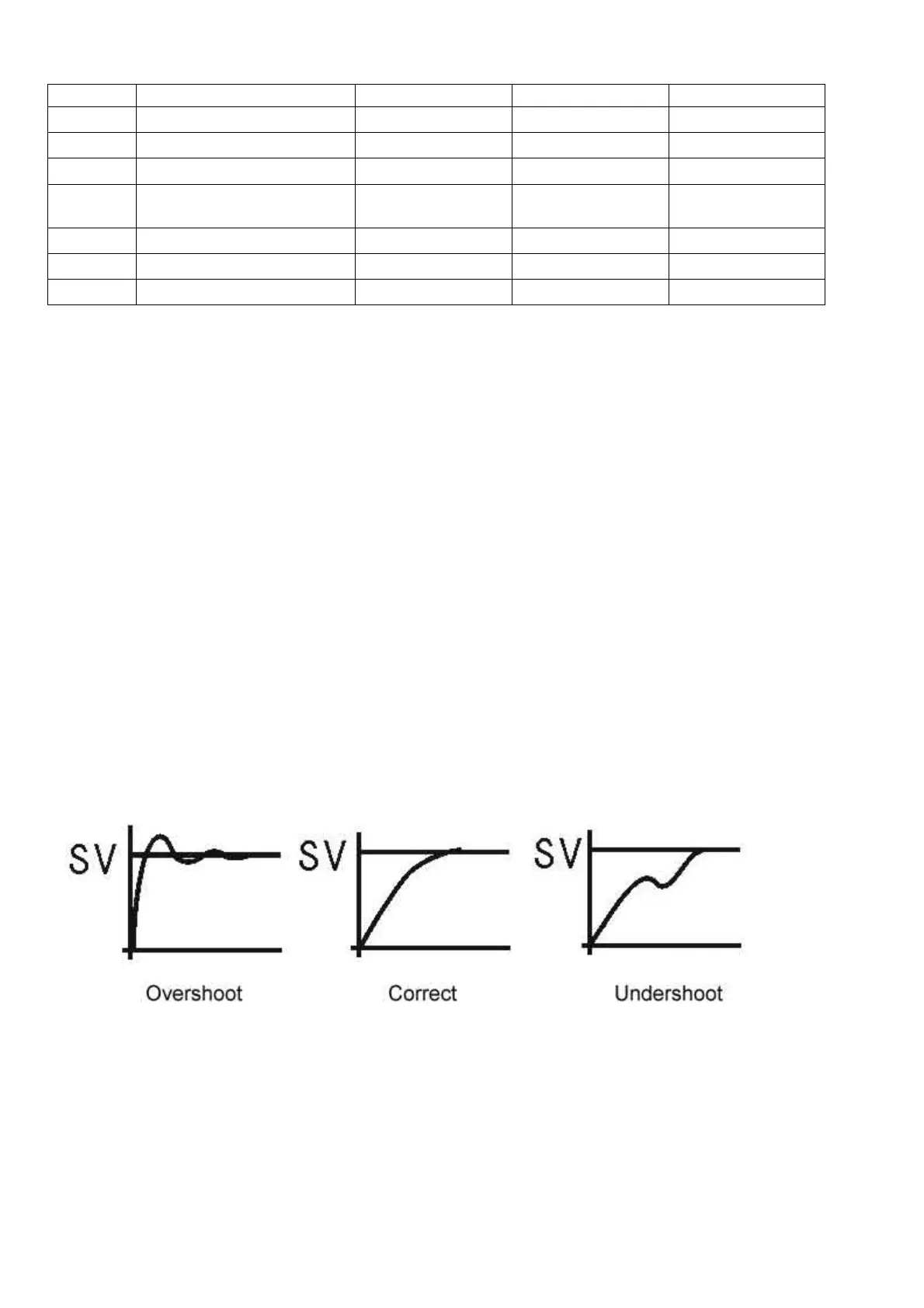

Note 7

Overshoot suppression coefficient. When overshoot exists, increase SouF. When undershoot

exists, decrease SouF.

Note 8

Control Period (ot): When ot gets smaller, heating/cooling cycle is drived faster, system respond

speed is faster. But when using contact control (Relays), contacts wear out faster.

When contact control (Relay) is used, normally set ot=5~15.

When non-contact control (SSR) is used, normally set ot=2.

Loading...

Loading...